Plasma cavity and precleaning equipment for physical vapor deposition

A plasma and chamber technology, used in ion implantation plating, electrical components, coatings, etc., can solve problems such as uneven plasma density distribution, and achieve the effect of improving processing quality, uniform ion density, and uniform processing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

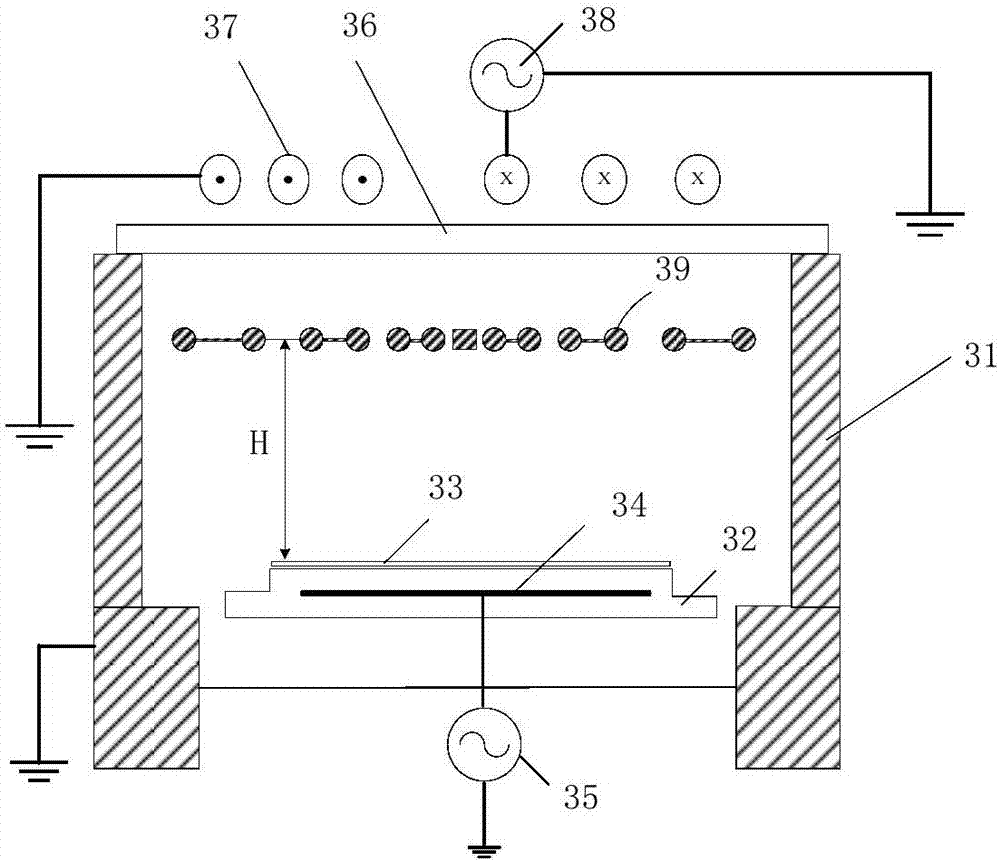

[0081] According to an embodiment of the plasma chamber of the present invention, the plasma adjusting device further includes a screw and a driving device, wherein one end of the screw is screwed to the ring, and the other end is connected to the driving device; and the driving device drives the screw to rotate, The ring is driven to move up and down along the screw, thereby adjusting the distance between the ring and the base.

[0082] As an embodiment of the present invention, the plasma processing equipment includes a position adjustment device (not shown in the figure), the position adjustment device is connected to the plasma adjustment device 39, and the position adjustment device can adjust the plasma adjustment device 39 according to the actual process characteristics The distance H from the base 32 is used to adjust the density distribution of the plasma in the cavity 31 . The position adjustment device includes a screw and a driving device (such as a screw adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com