Lead-silicon composite bipolar battery

A bipolar battery and battery case technology, applied in lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc., can solve problems such as uneven distribution and high current density, and achieve good electrical conductivity and current density. The effect of uniform distribution and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

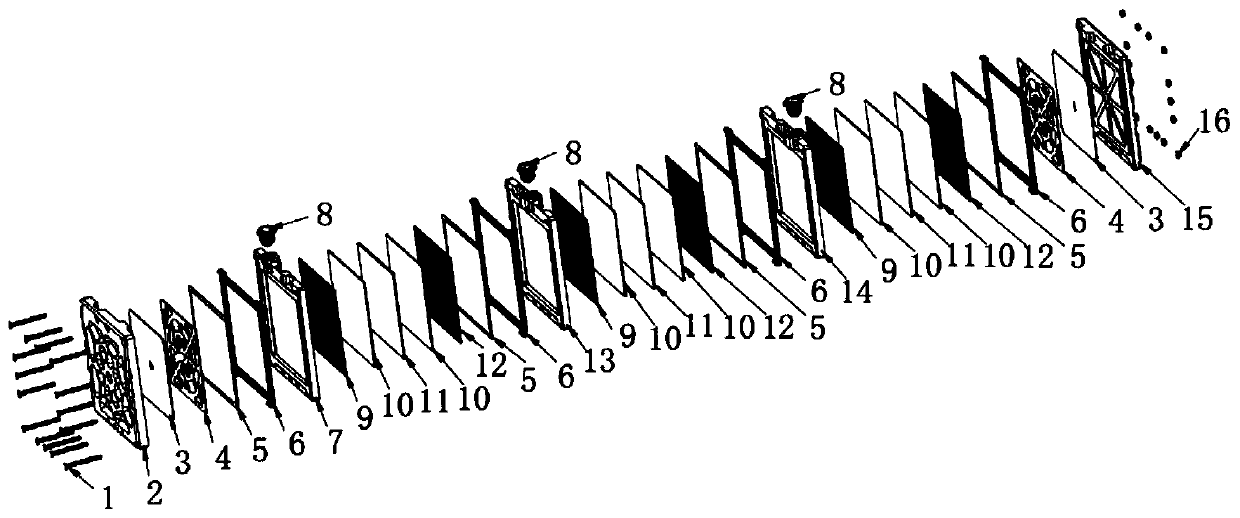

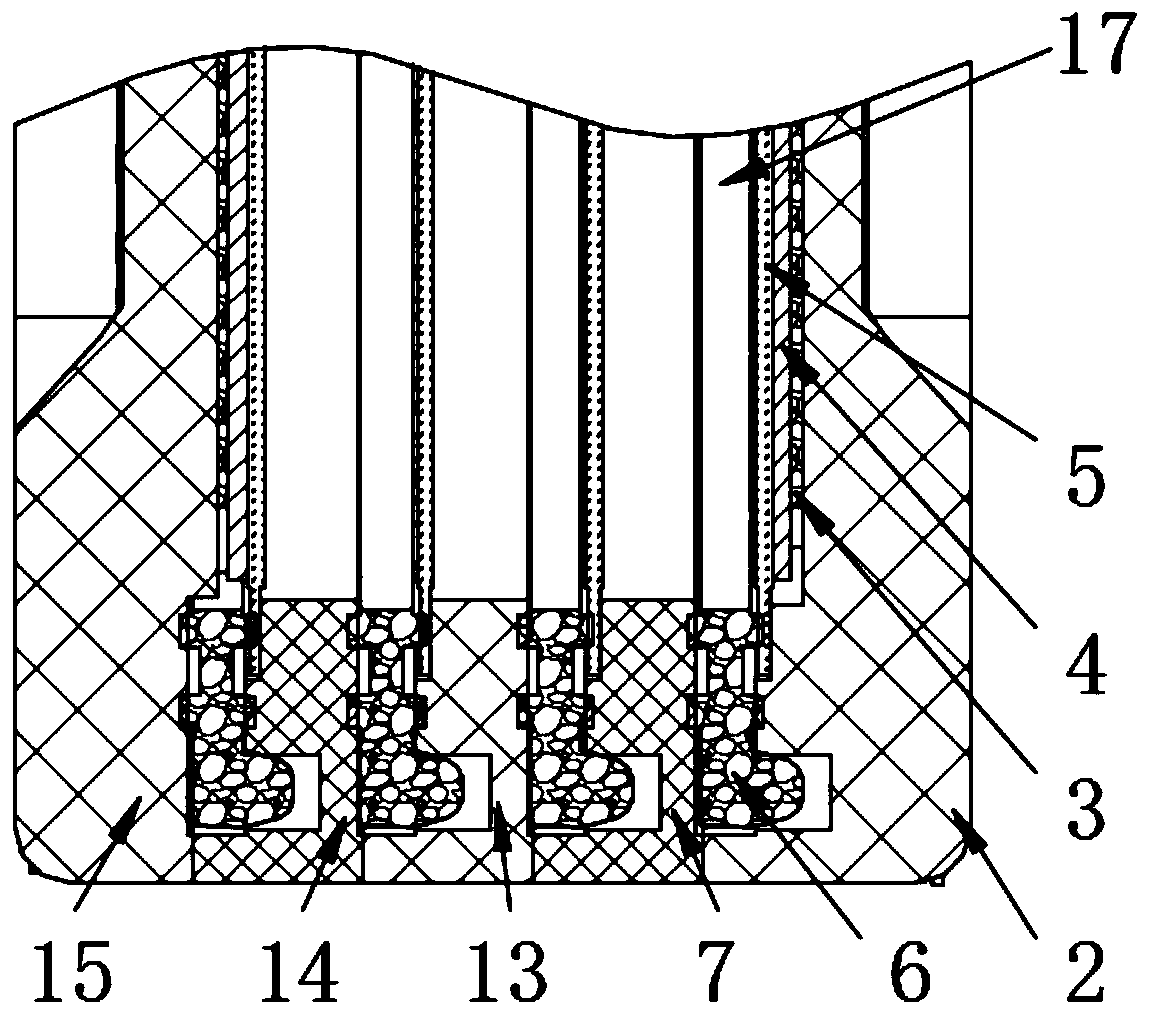

[0037] like figure 1 , 12 As shown, in the embodiment of the present invention, a lead-silicon composite bipolar battery electrode group includes a positive plate 9, a negative plate 12, a first separator 10 and a second separator 11, and the positive plate 9 and the negative plate The plates 12 are respectively formed by coating positive and negative active materials on the surface of the grid 18, and a first separator 10 and a second separator 11 are arranged between the positive plate 9 and the negative plate 12;

[0038] The grid 18 is a corrosion-resistant grid, and the grid 18 mainly plays the role of carrying the active material, and the positive active material is made of PbO 2 and positive electrode additives, and the negative active material is composed of spongy Pb and negative electrode additives. The plastic mesh grid 18 has the advantages of strong corrosion resistance and can significantly increase battery life. Compared with the lead grid of the existing stora...

Embodiment 2

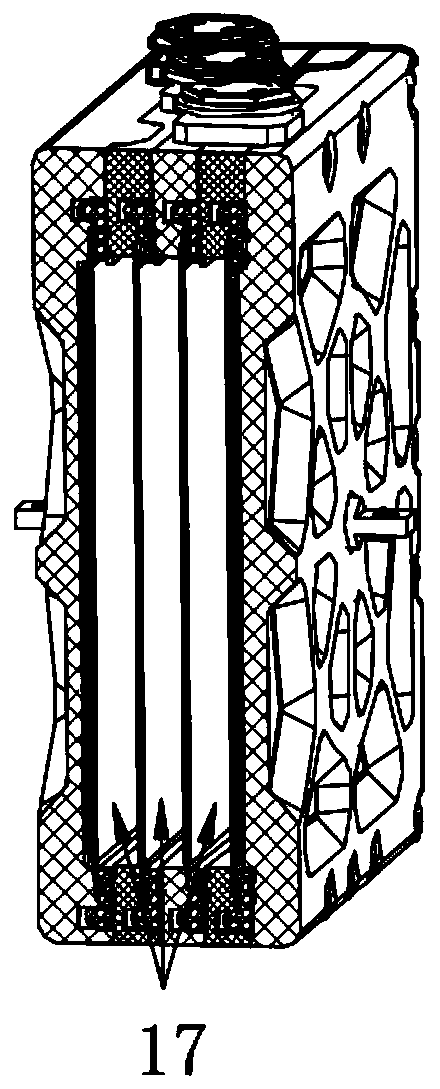

[0043] like Figure 1-16As shown, in the embodiment of the present invention, a lead-silicon composite bipolar battery includes the electrode group for the lead-silicon composite bipolar battery as described in Example 1, and also includes a fastening screw 1, a first battery case 2. The second battery case 7, the third battery case 13, the fourth battery case 14 and the fifth battery case 15, the first battery case 2 and the second battery case are arranged in sequence from top to bottom inside the battery 7. The third battery case 13, the fourth battery case 14, and the fifth battery case 15. The bottom of the first battery case 2 is evenly distributed with a plurality of fastening screws 1, and the upper ends of the fastening screws 1 pass through the first The battery case 2, the second battery case 7, the third battery case 13, the fourth battery case 14 and extend to the top of the fifth battery case 15, the same number of nuts 16 are evenly distributed on the upper part...

Embodiment 3

[0051] like Figure 1-16 As shown, in the embodiment of the present invention, a lead-silicon composite bipolar battery includes the electrode group for the lead-silicon composite bipolar battery as described in Example 1, and also includes a fastening screw 1, a first battery case 2. The second battery case 7, the third battery case 13, the fourth battery case 14 and the fifth battery case 15, the first battery case 2 and the second battery case are arranged in sequence from top to bottom inside the battery 7. The third battery case 13, the fourth battery case 14, and the fifth battery case 15. The bottom of the first battery case 2 is evenly distributed with a plurality of fastening screws 1, and the upper ends of the fastening screws 1 pass through the first The battery case 2, the second battery case 7, the third battery case 13, the fourth battery case 14 and extend to the top of the fifth battery case 15, the same number of nuts 16 are evenly distributed on the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com