Method for eliminating horizontal current in aluminum cell aluminum liquor

An aluminum electrolytic cell and horizontal current technology, which is applied in the field of equipment-aluminum electrolytic cell, can solve the problems of high current density of cathode carbon blocks, reduce current efficiency, imbalance of aspect ratio, etc., achieve uniform current density distribution, improve current efficiency, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

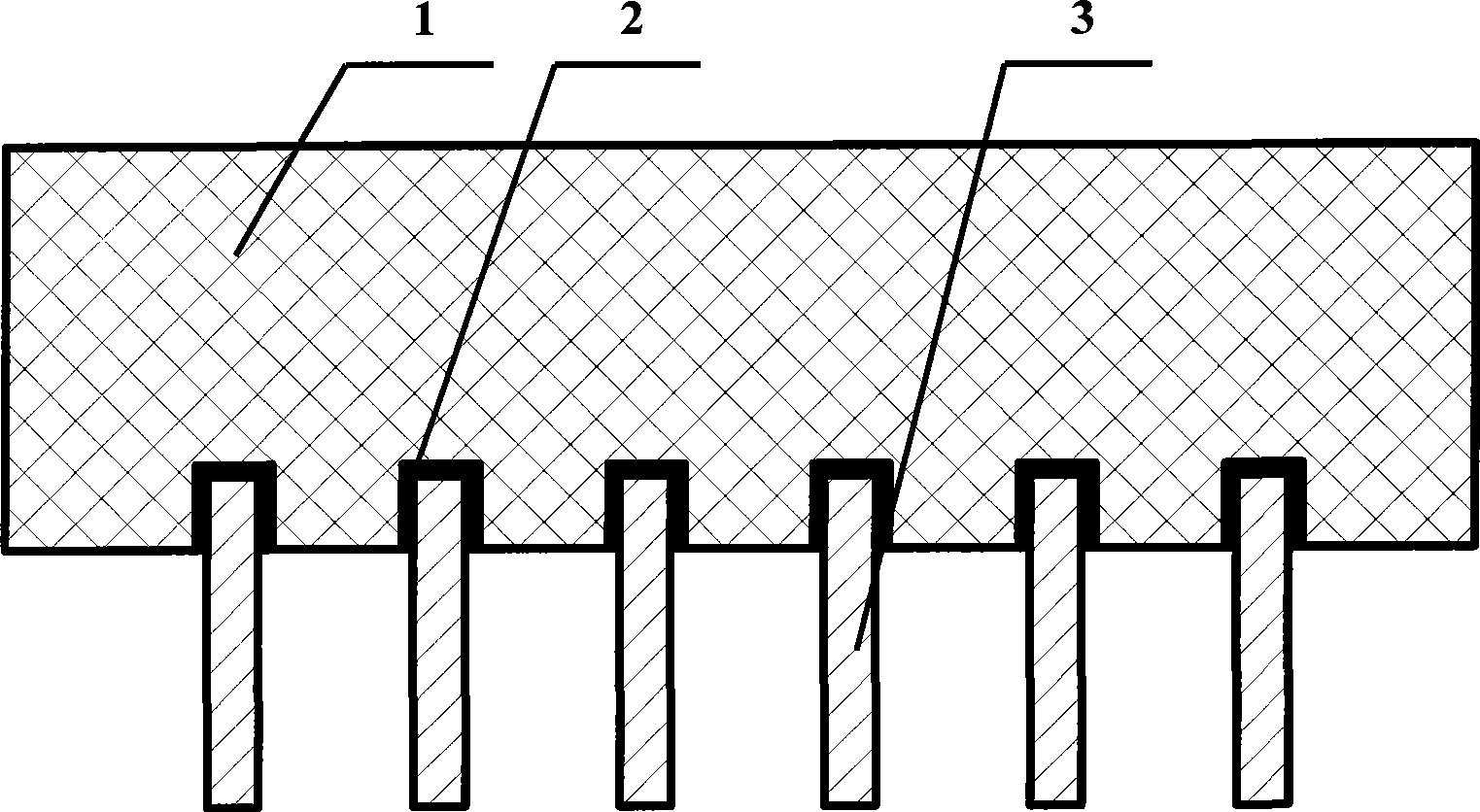

[0043] like figure 1 As shown, the method for eliminating the horizontal current in the aluminum liquid of the aluminum electrolytic cell is as follows: 1 to 100 connecting conductors 3 are arranged at the bottom of the cathode carbon block 1, and the connecting conductors 3 are any conductive materials such as steel rods or steel plates. One end of the conductor 3 is embedded in the cathode carbon block 1 through phosphorus pig iron or paste 2, and the connecting conductor 3 and the cathode carbon block 1 can be arranged vertically. The other end of the connecting conductor 3 passes directly from the bottom of the tank, so that the current passes through the aluminum liquid and the cathode carbon block 1 substantially vertically, thus eliminating the horizontal current in the aluminum liquid.

Embodiment 2

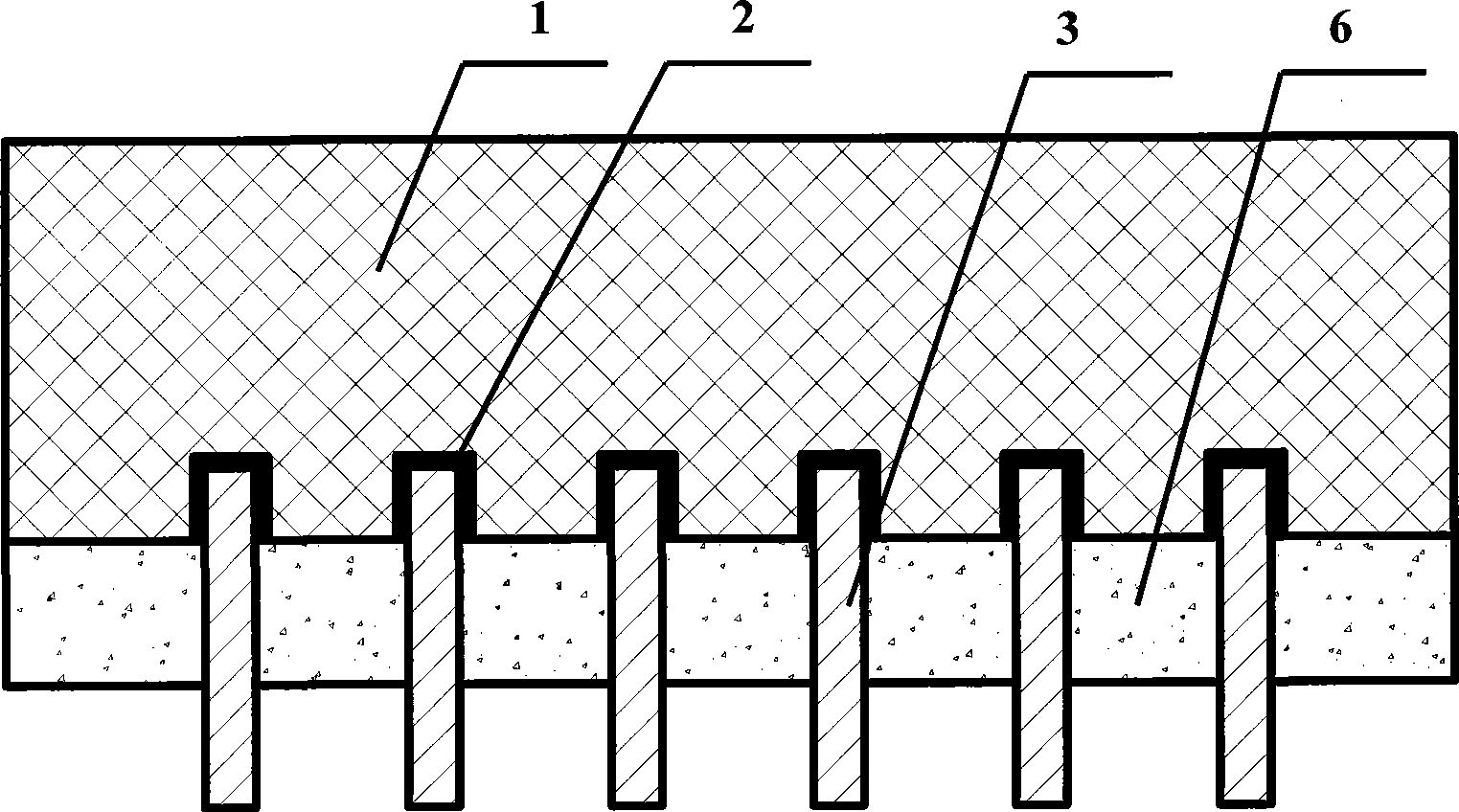

[0045] like figure 2 As shown, the method for eliminating the horizontal current in the aluminum liquid of the aluminum electrolytic cell is as follows: 1 to 100 connecting conductors 3 are arranged at the bottom of the cathode carbon block 1, and the connecting conductors 3 are any conductive materials such as steel rods or steel plates. One end of the conductor 3 is embedded in the cathode carbon block 1 through phosphorus pig iron or paste 2, and the connecting conductor 3 and the cathode carbon block 1 can be arranged vertically. The other end of the connecting conductor 3 passes directly from the bottom of the tank, so that the current passes through the aluminum liquid and the cathode carbon block 1 substantially vertically, thus eliminating the horizontal current in the aluminum liquid. In order to prevent electrolyte or aluminum liquid from leaking and corroding the connecting conductor 3, an anti-seepage material 6 is arranged under the cathode carbon block 1. The an...

Embodiment 3

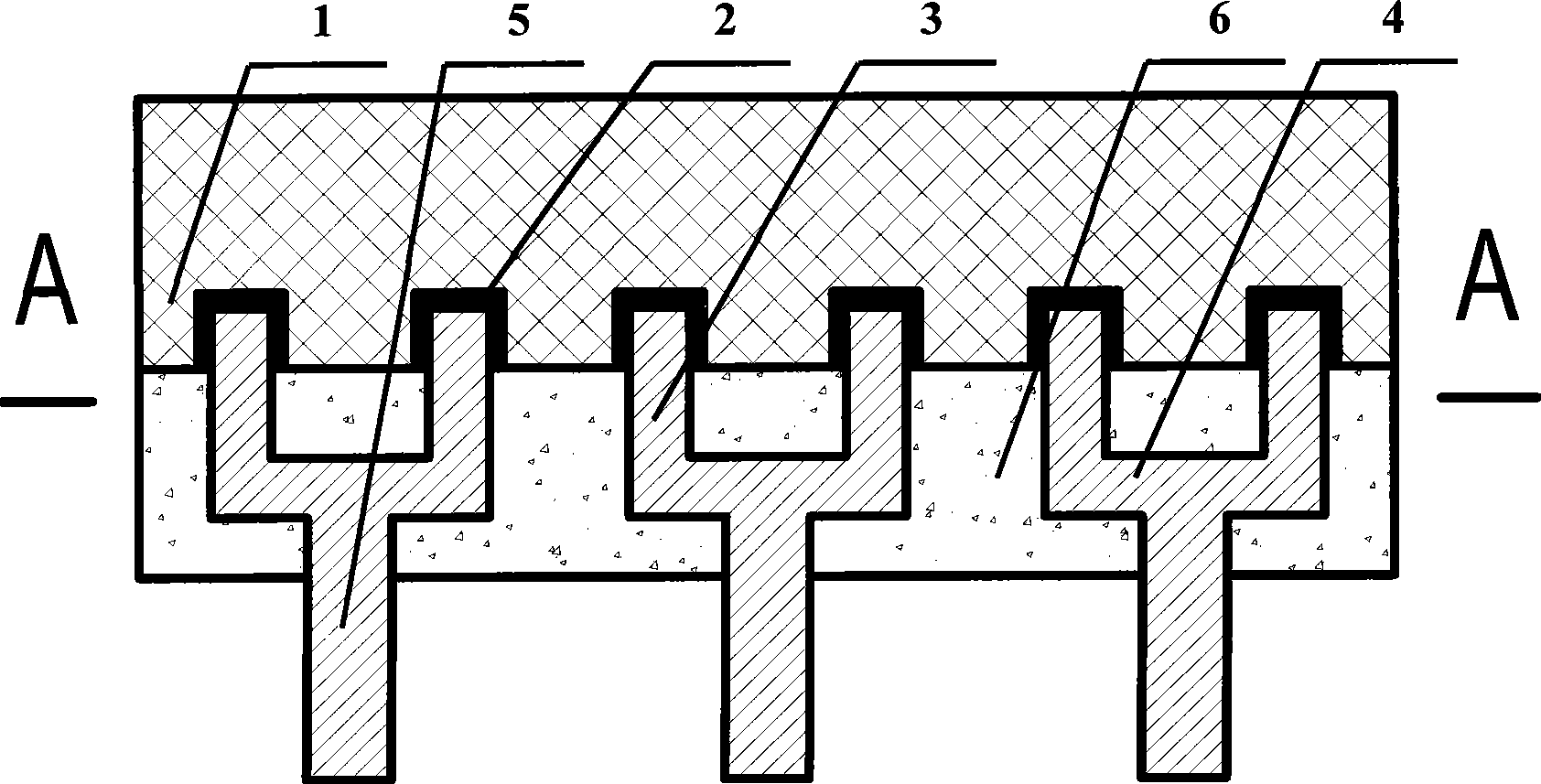

[0047] like image 3 , Figure 7 and Figure 8 As shown, the method for eliminating the horizontal current in the aluminum liquid of the aluminum electrolytic cell is as follows: 2 to 100 connecting conductors 3 are arranged on the lower part of the cathode carbon block 1, and the connecting conductors 3 and the cathode carbon block 1 can be arranged vertically. The anti-seepage material 6 is set under the carbon block 1, and one end of the connecting conductor 3 is embedded in the cathode carbon block 1 through phosphorus pig iron or paste 2; Two or more connecting conductors 3 at this end of the permeable material 6 are connected to the lead-out conductor 5 through the bus conductor 4, and the lower end of the lead-out conductor 5 stretches out the anti-seepage material 6 and passes out from the bottom of the groove. The lead-out conductor 5 is located directly below the cathode carbon block 1 . The connecting conductor 3 and the bus conductor 4 are all wrapped in the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com