Process for manufacturing premelting anode aluminium electrolytic tank

A technology for aluminum electrolytic cells and prebaked anodes, which is applied in the field of aluminum electrolytic cells, and can solve problems such as unsatisfactory use effects, damage to aluminum electrolytic cells, and reduced service life of electrolytic cell linings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

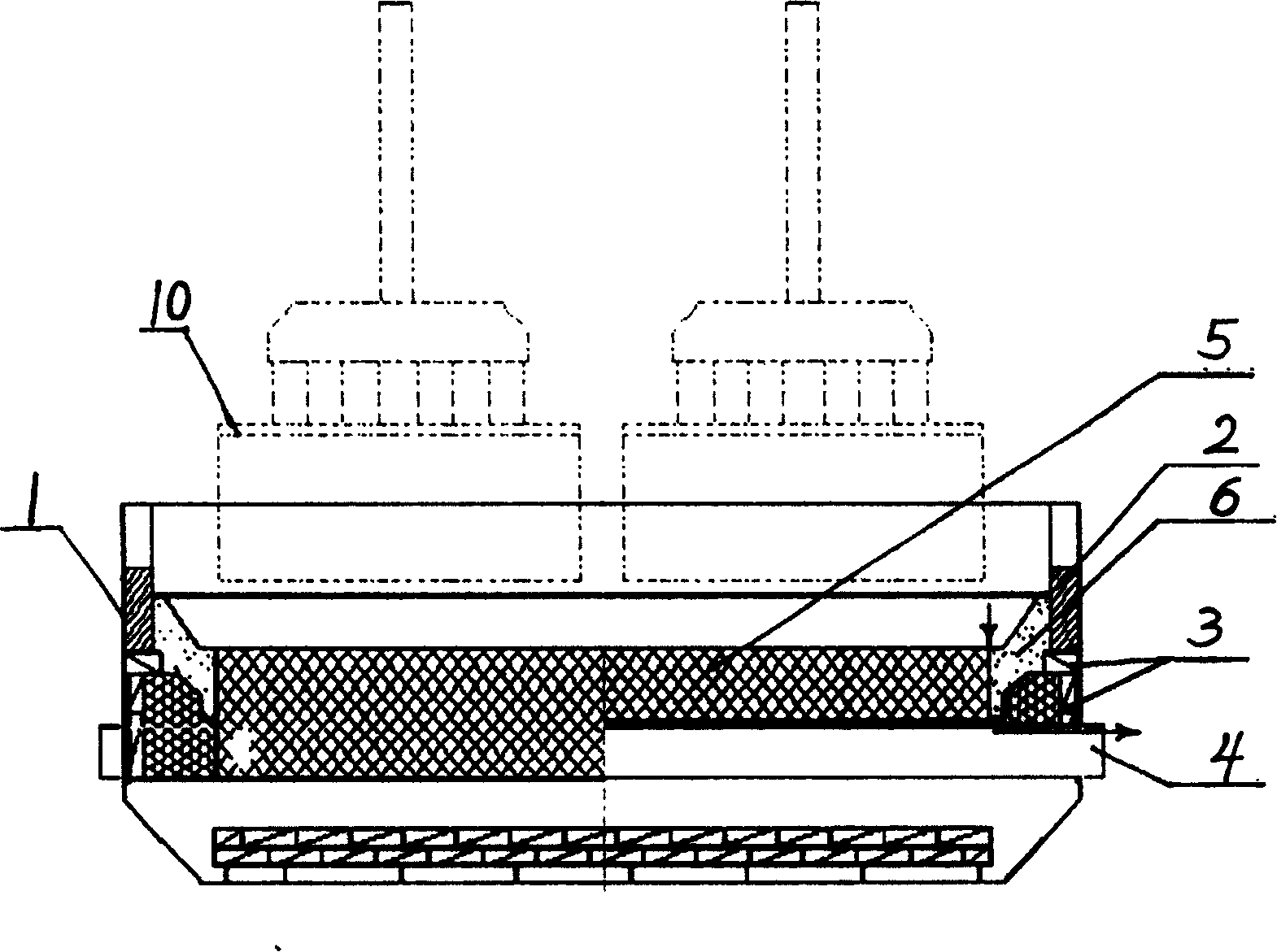

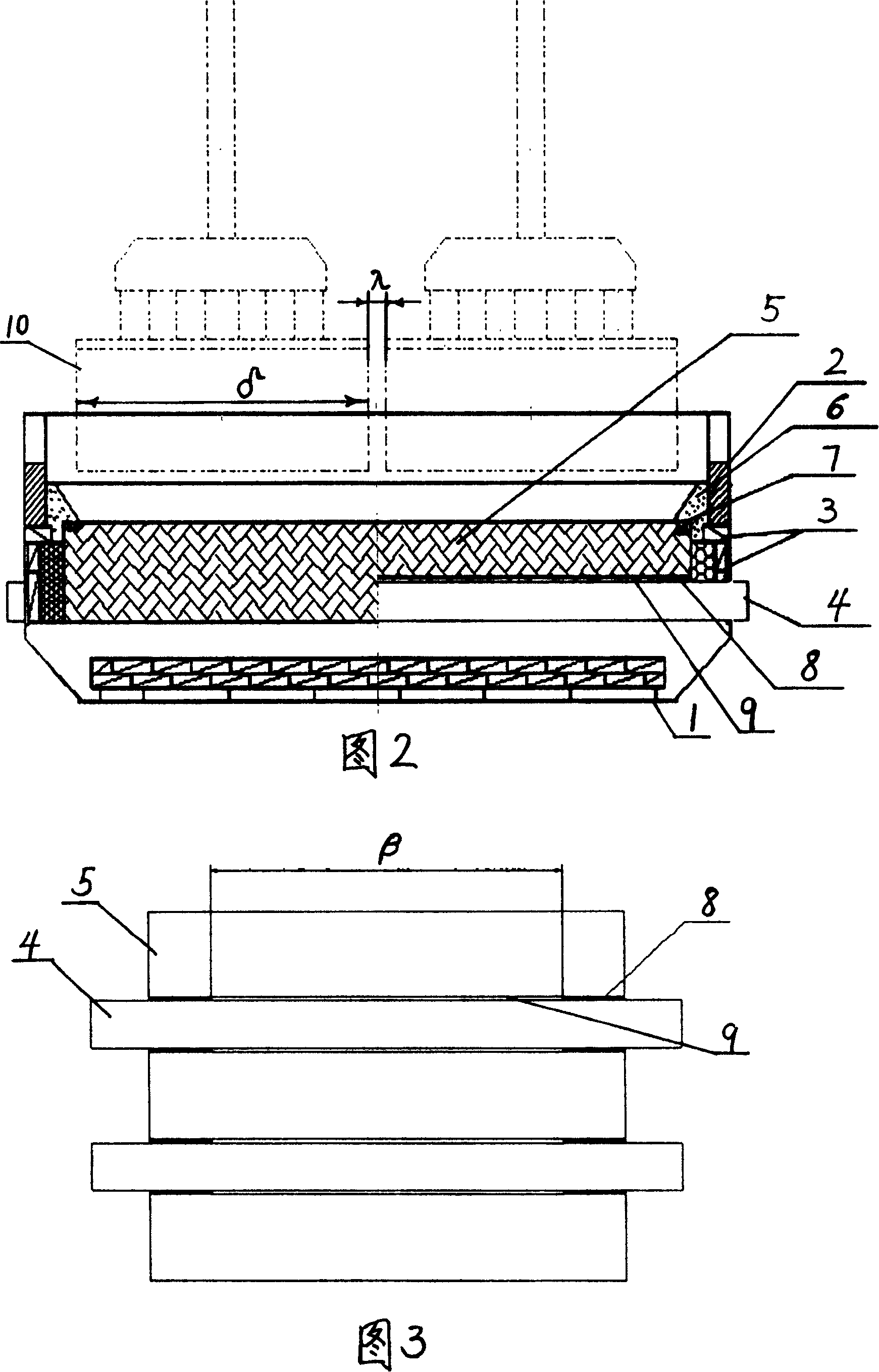

[0009] Embodiments of the present invention: the adopted prebaked anode aluminum electrolytic cell housing (1), side carbon block (2), insulation brick (3), cathode steel rod (4), cathode carbon block (5) and belt The structure and material of the paste (6) around the carbon edge of the inclined plane are all the same as the prior art. When making, the two ends of the cathode carbon block (5) are lengthened by 30mm to 80mm respectively to be arranged on the paste (6) around the edge. The bottom of the inclined plane makes the inclined plane of the paste (6) around the edge cover the two ends of the cathode carbon block (5), and the two sides of the cathode carbon block (5) are covered by the inclined plane of the paste (6) around the edge. Make 1 to 3 grooves (7) with a width of 10mm and a depth of 10mm on the top of the end, and fill the grooves (7) with the same material as the paste (6) around the edge; in order to prevent horizontal The current can be isolated between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com