Cathode structure of aluminum cell vertical cathode steel bar current outlet

A cathode steel rod and aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve problems such as poor working stability, affecting the stability of the electrolytic cell, and the inability of the electrolytic cell to achieve normal production, eliminating horizontal current, avoiding leakage and Broken, weakened effect of waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

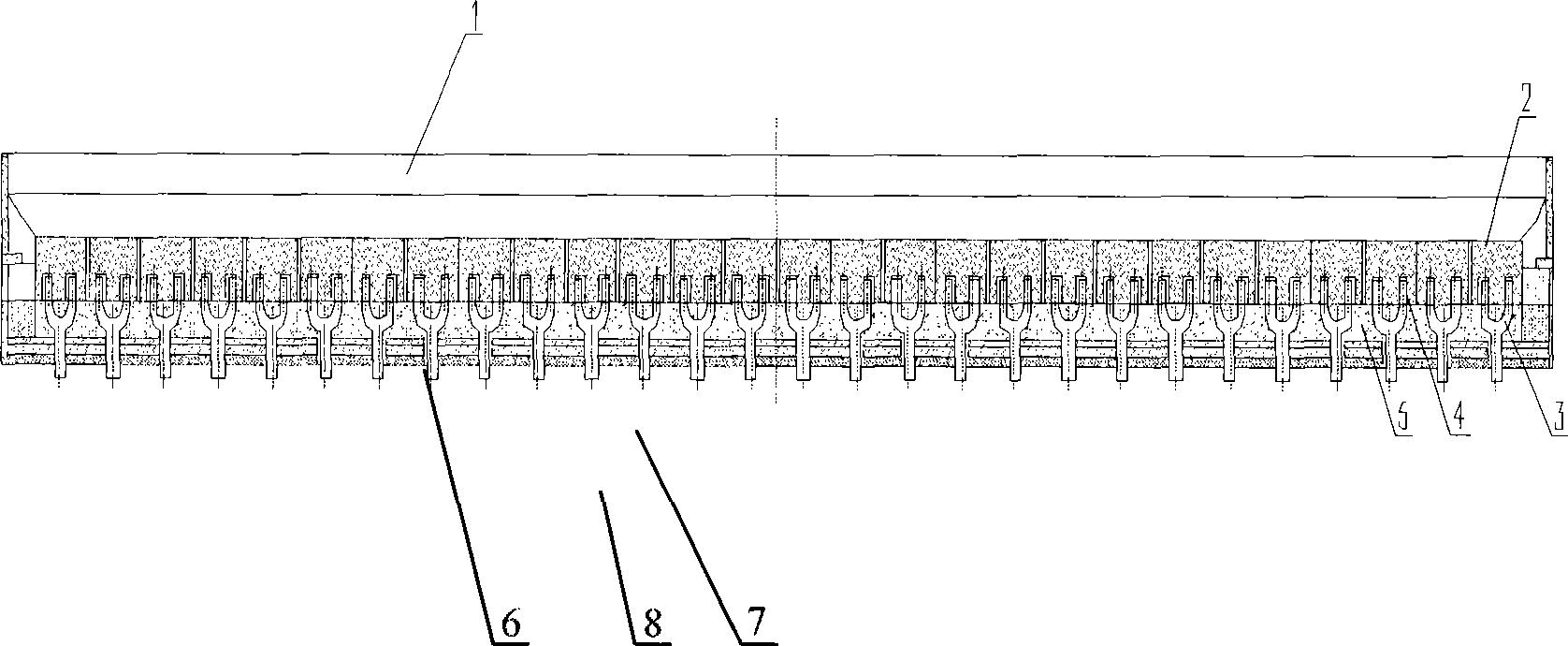

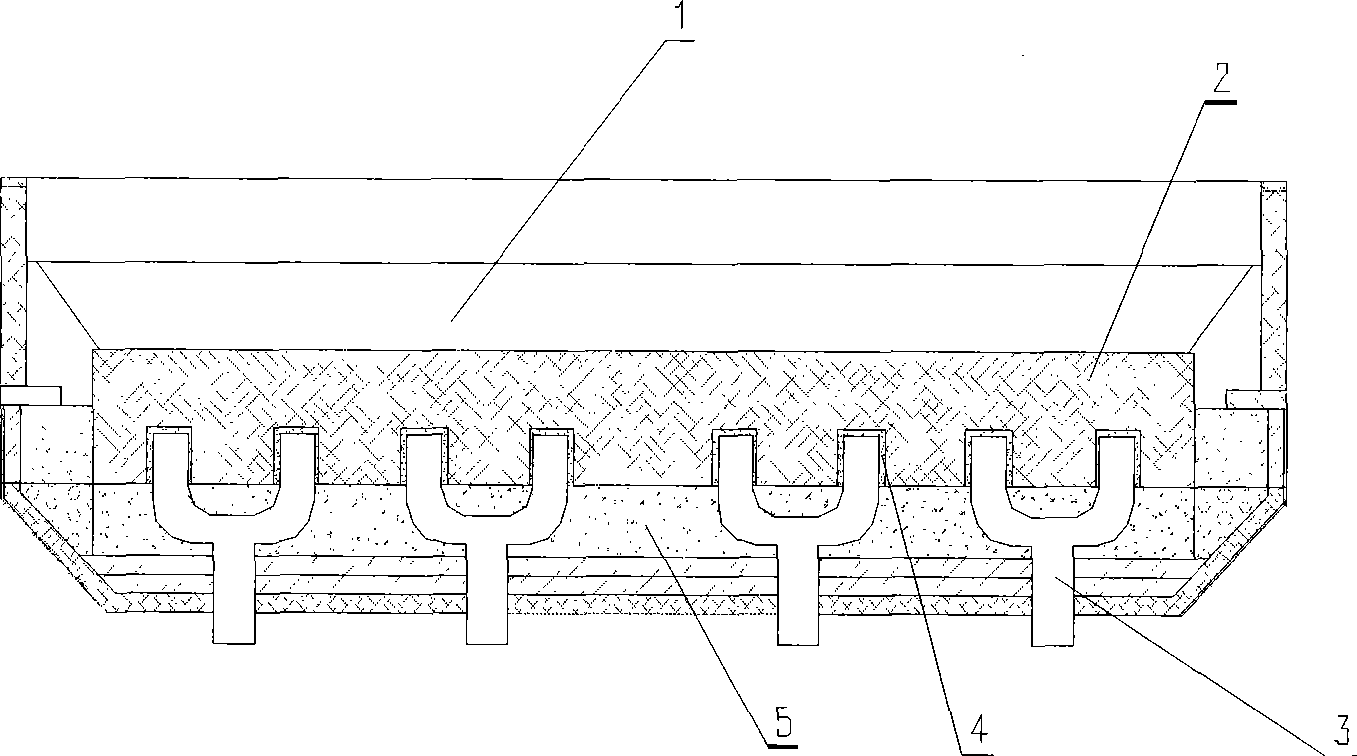

[0014] see figure 1 with figure 2 , the cathode structure of the vertical cathode steel bar of the aluminum electrolytic cell provided by the embodiment of the present invention includes a cathode lining 1, a cathode carbon block 2 and a cathode steel rod 3, the cathode carbon block 2 is located inside the cathode liner 1; the cathode steel rod 3 is composed of cathode steel claw 6, bus steel rod 7 and conductive steel rod 8; cathode steel rod 3 is vertically connected to the bottom of cathode carbon block 2 through cathode steel claw 6, and passes through the bottom of cathode lining 1.

[0015] In practical applications, the cathode carbon block 2 and the cathode steel rod 3 are connected by pouring or solidified high-conductivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com