Cathode conductive structure

A technology of cathode conduction and conductive rods, which is applied in the field of aluminum electrolytic cells, can solve the problems of limited space for improving current efficiency, loss of current efficiency, and instability of electrolytic cells, etc., and achieves shortened conductive path, elimination of horizontal current, and reduced cathode voltage drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

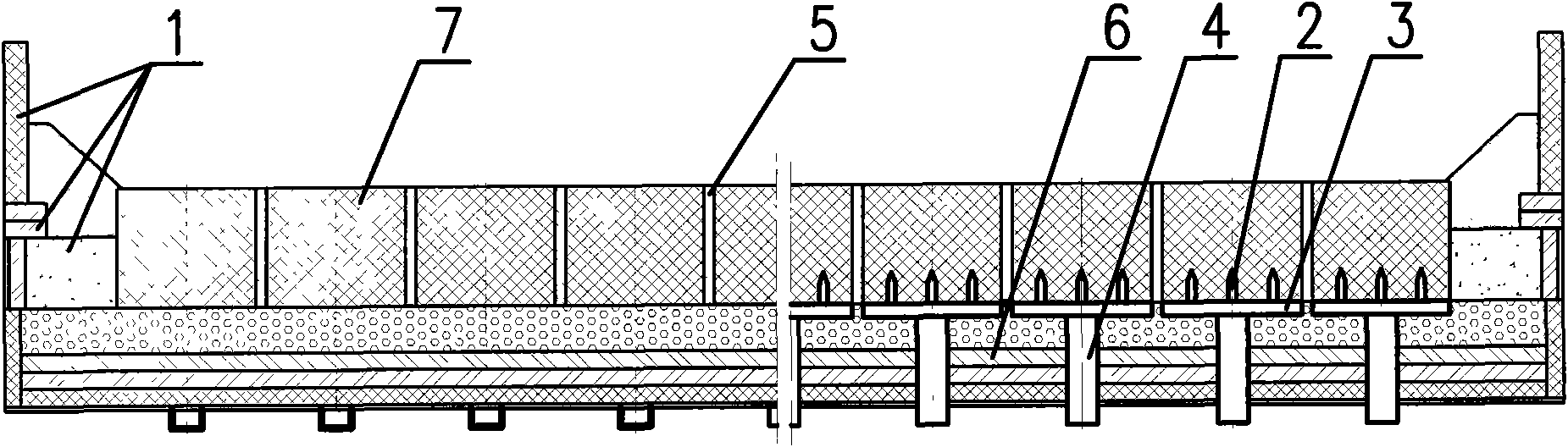

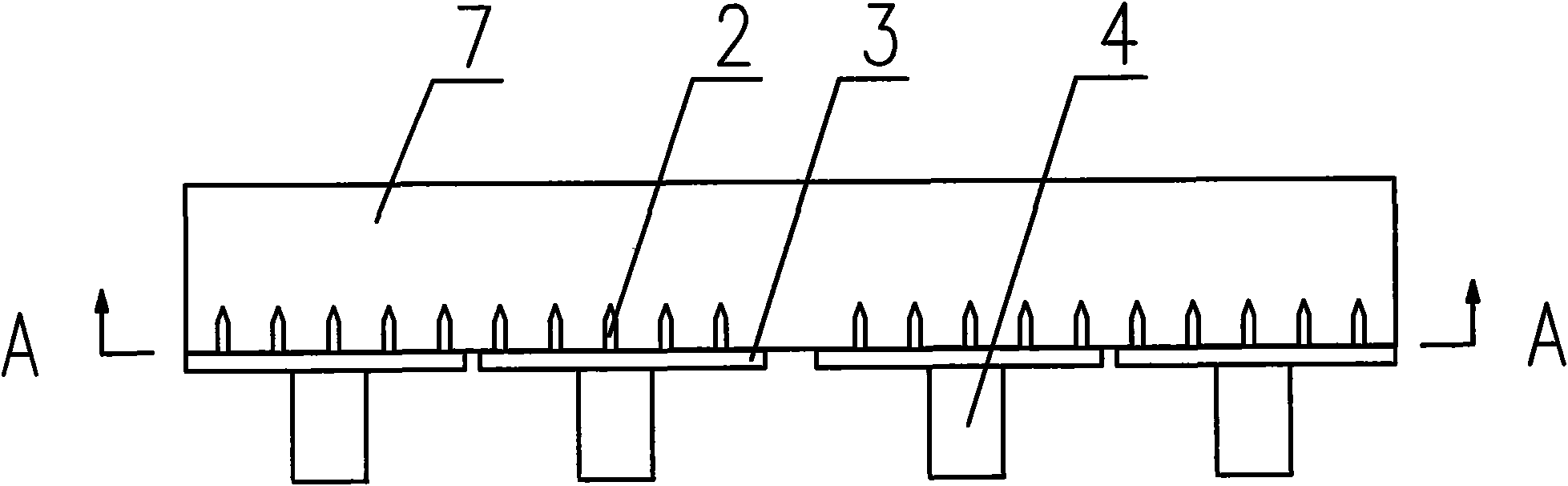

[0028] like figure 1 As shown, the cathode conductive structure of the present invention is composed of a side lining 1 , a cathode carbon block 7 , a paste 5 between the cathode carbon blocks, and a bottom lining 6 . Conductive screws 2 are installed vertically at the bottom of the cathode carbon block, and the number of conductive screws 2 installed at the bottom of each group of cathode carbon blocks 7 is 1-2000. Every 1 to 500 conductive screws 2 are connected to a conductive rod 4 through a conductive plate 3, and the conductive rod 4 passes through the bottom lining 6 to pass through the bottom of the groove, and the conductive rod 4 can also pass through the side of the groove, such as figure 1 Only the case of piercing from the bottom is shown, but the scope of protection is not limited by the legend. The present invention is applicable to cathode carbon blocks 7 of various cross-sectional shapes, and the end of the cathode carbon block 7 and the side lining 1 are tam...

Embodiment 2

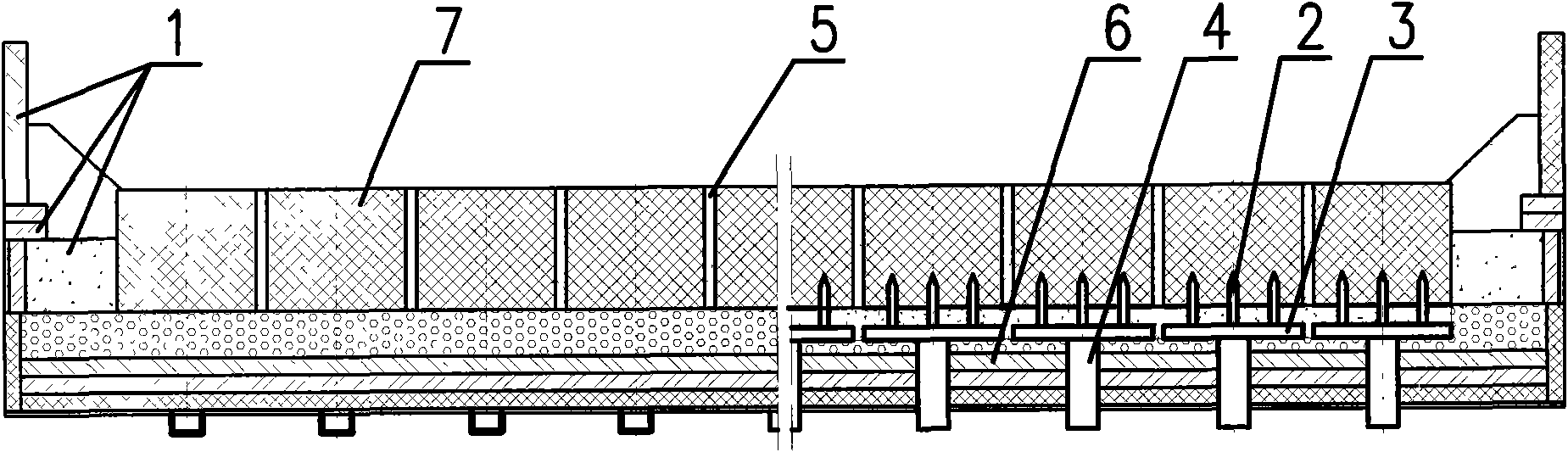

[0030] like figure 2 As shown, the cathode conductive structure of the aluminum electrolytic cell is composed of a side lining 1, a cathode carbon block 7, a paste between the cathode carbon blocks 5, and a bottom lining 6. Conductive screws 2 are vertically installed at the bottom of the cathode carbon block, and the number of conductive screws 2 installed at the bottom of each group of cathode carbon blocks 7 is 1 to 4000, and 2 to 1000 conductive screws 2 are connected to a conductive rod 4 through a conductive plate 3, The conductive rod 4 passes through the bottom lining 6 and passes through the bottom of the groove, and the conductive rod 4 can also pass through the side of the groove. figure 2 Only the case of piercing from the bottom is shown, but the scope of protection is not limited by the legend. The present invention is applicable to cathode carbon blocks 7 of various cross-sectional shapes, and the cross-sectional shapes of the cathode carbon blocks 7 may be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com