Electroplating electric-conducting device for integrated circuit lead frame

A technology of lead frames and integrated circuits, applied in circuits, electrical components, electrolytic processes, etc., can solve the problems of uneven distribution of current density, uneven thickness of silver layer, increased production costs, etc., achieve uniform distribution of current density, reduce silver The loss and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The electroplating conductive device of the integrated circuit lead frame of the present invention will be further described in detail through specific embodiments below.

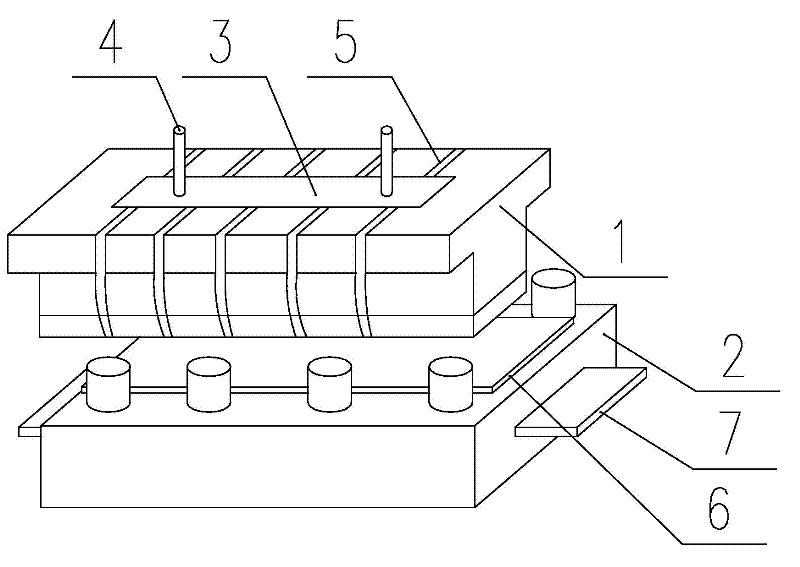

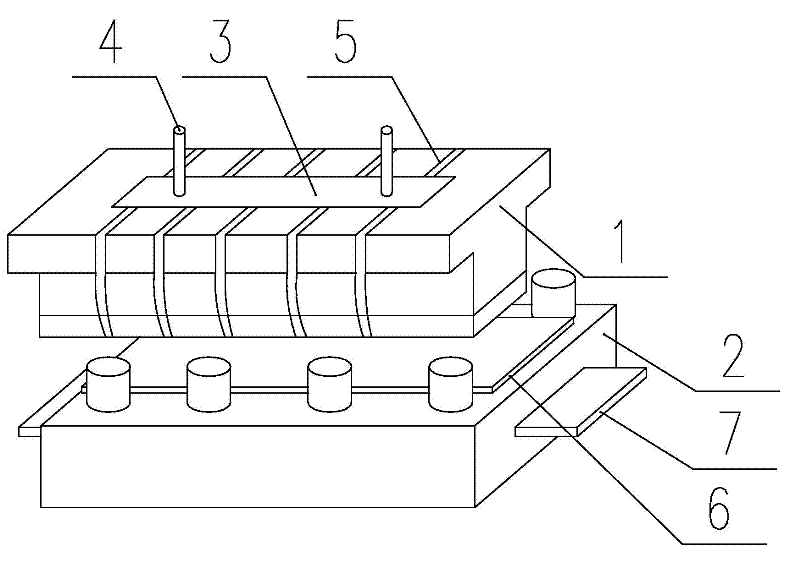

[0012] Such as figure 1 As shown, the electroplating conductive device of the integrated circuit lead frame includes an upper mold 1 and a lower mold 2, the upper mold 1 is provided with a conductive strip 3, and the conductive strip 3 is provided with two binding posts 4, and the two conductive strips 3 At least three pins 5 are respectively arranged along the lateral direction, and the ends of the pins 5 extend to the bottom of the upper mold 1 . In this embodiment, six pins 5 are arranged on both sides of the conductive strip 3 along the transverse direction. An anode plate 7 is arranged in the lower mold 2 .

[0013] The working principle of the present invention is: when the integrated circuit lead frame 6 is electroplated, the lead frame 6 is first sent between the upper die 1 and the lower d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com