Lithium battery of high specific energy and high power, and manufacturing method thereof

A manufacturing method and technology for lithium batteries, which are applied in secondary batteries, battery pack components, and final product manufacturing, etc., can solve the problems of reduced energy density and ineffectiveness of cells, and achieve low calorific value, high power, and current. The effect of uniform density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

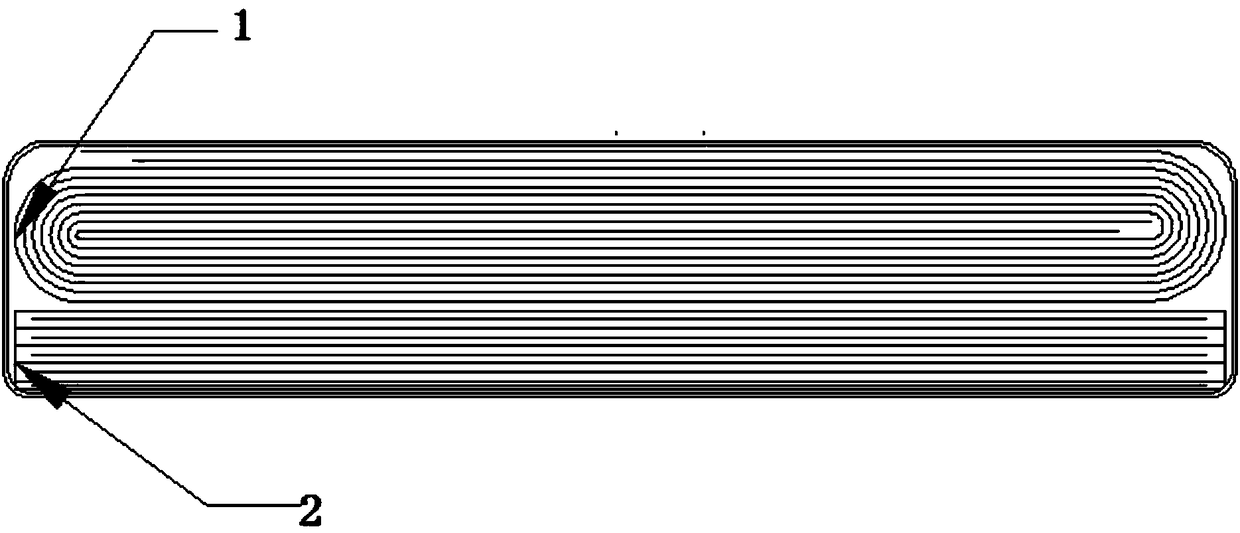

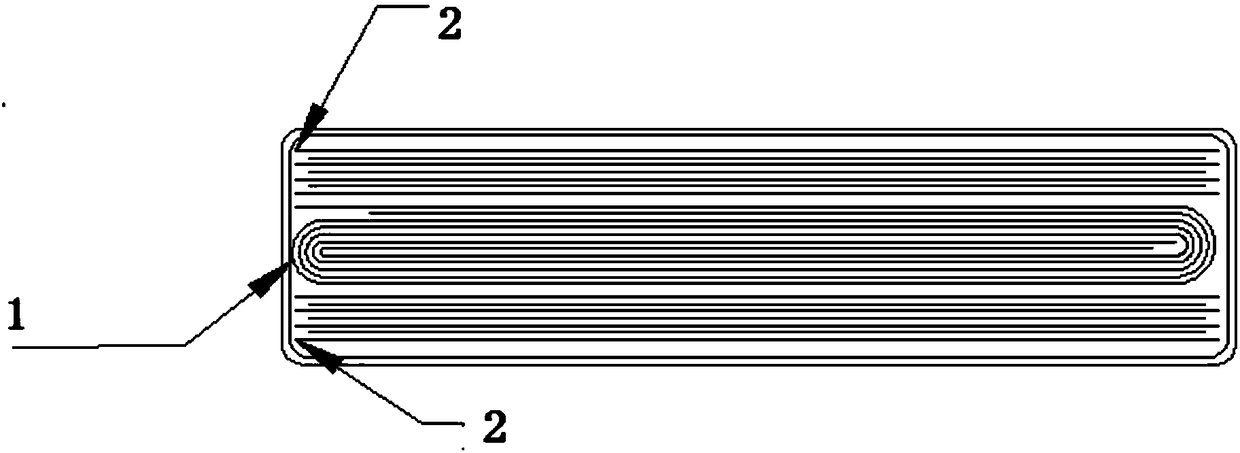

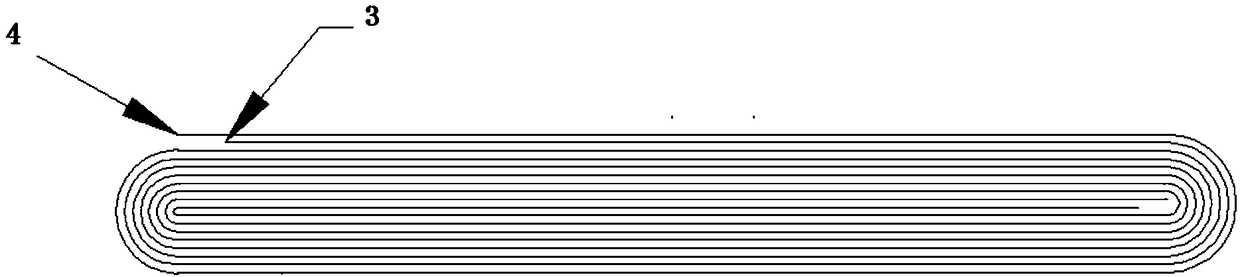

[0041] The positive electrode sheet 3 with a length of 2681 mm and a width of 92 mm and the negative electrode sheet 4 with a length of 2928 mm and a width of 96 mm were wound in a manner of wrapping the positive electrode with the negative electrode, and fixed with a termination tape to obtain the first cell 1 . Die-cutting the positive electrode sheet 3 with a width of 92 mm and a length of 865 mm into a positive electrode sheet 5 with a width of 72 mm and a length of 92 mm; a die-cutting of a negative electrode sheet 4 with a width of 96 mm and a length of 915 mm into a negative electrode sheet 6 with a width of 74 mm and a length of 96 mm; The cut positive and negative pole pieces 6 are equally divided into two parts, and two second battery cells 2 are obtained through one positive and one negative lamination, and the two second battery cells 2 are connected in parallel with the first battery cell 1 to obtain the final battery cell. core.

Embodiment 2

[0043] The positive electrode sheet 3 with a length of 2681 mm and a width of 92 mm and the negative electrode sheet 4 with a length of 2928 mm and a width of 96 mm were wound in a manner of wrapping the positive electrode with the negative electrode, and fixed with a termination tape to obtain the first cell 1 . Die-cutting the positive electrode sheet 3 with a width of 92 mm and a length of 865 mm into a positive electrode sheet 5 with a width of 72 mm and a length of 92 mm; a die-cutting of a negative electrode sheet 4 with a width of 96 mm and a length of 915 mm into a negative electrode sheet 6 with a width of 74 mm and a length of 96 mm; The cut positive and negative electrode sheets 6 are divided into three parts on average, and the positive and negative electrode sheets 4 of one part are laminated to the first part of the second battery cell 2 through one positive and one negative sheet, and then the two parts of the positive and negative electrode sheets are 4 Obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com