Welding method of composite copper bar conducting layer, and composite copper bar

A composite copper bar and welding method technology, applied in welding equipment, circuits, electrical components and other directions, can solve the problems of inability to install leads on the composite copper bar matrix, inability to install leads, strength reduction, etc., to prevent softening and deformation, reduce heat, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment provides a method for welding a conductive layer of a composite copper row, comprising the following steps:

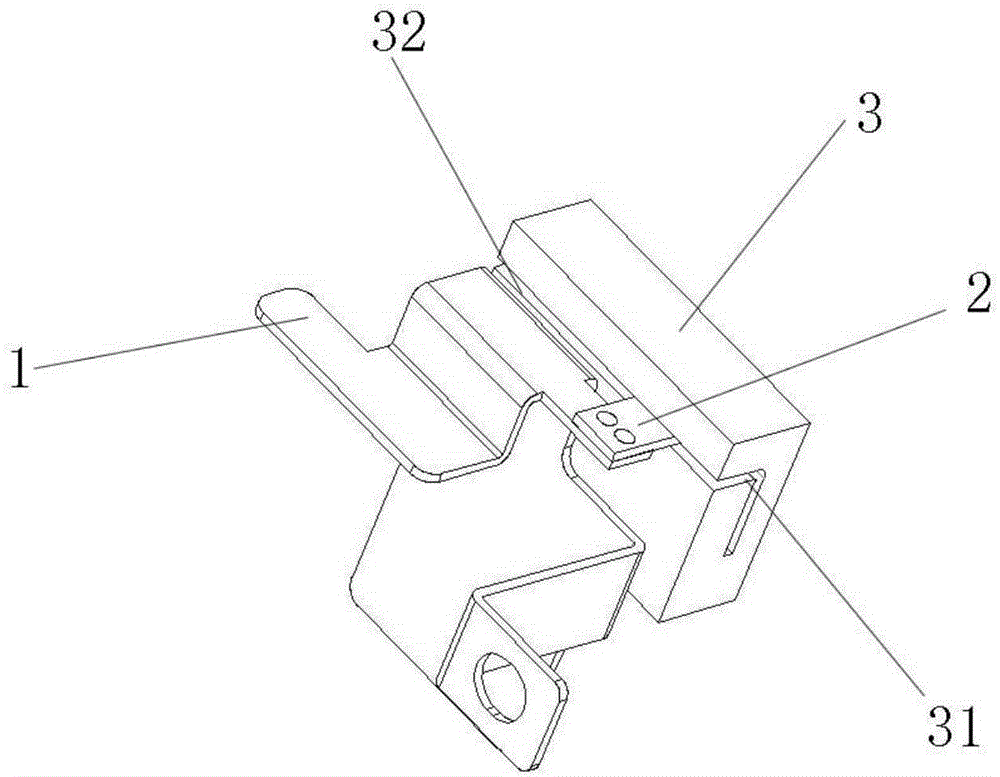

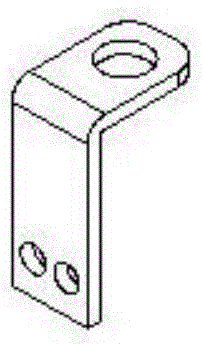

[0040] S1: Insert the lead workpiece 2 (such as figure 2 As shown, it is made of copper or copper alloy, and the shape is composed of two straight plates that are perpendicular to each other and connected together to form an L shape. The welding part of the hole) is positioned on the installation part of the copper bar base 1 through the positioning structure;

[0041]S2: Fill brazing material between the lead workpiece 2 and the copper bar base 1, and place the non-welded part of the lead workpiece 2 in the heat dissipation mold 3;

[0042] S3: Using the resistance brazing process, the brazing material is melted by heating the resistance block, so that the lead workpiece 2 and the copper bar base 1 are welded and fixed (such as figure 1 shown);

[0043] The resistance brazing process includes:

[0044] a: Preheat the two resistance b...

Embodiment 2

[0061] This embodiment provides a welding method for a conductive layer of a composite copper bar. The difference between this embodiment and Embodiment 1 lies in the specific parameters of the resistance brazing process.

[0062] The resistance brazing process of this embodiment includes:

[0063] a: Preheat the two resistance blocks used as the upper mold and the lower mold to 100°C higher than the melting temperature of the brazing material;

[0064] b: Quickly place the mounting part of the copper bar base 1 and the welding part of the lead workpiece 2, which have been positioned together by the positioning structure, between the two resistor blocks, so that the two resistor blocks are connected to the mounting part and the mounting part with a pressure of 0.3MPa The welding part is fit;

[0065] c: Continue to pass 800A current to the resistance block, and weld for 8s to fully melt the solder;

[0066] d: After disconnecting the current, keep the pressure for 15s to com...

Embodiment 3

[0068] This embodiment provides a welding method for the conductive layer of the composite copper bar. The difference between this embodiment and Embodiment 1 or Embodiment 2 lies in the resistance brazing process.

[0069] The resistance brazing process of this embodiment includes:

[0070] a: Preheat the two resistance blocks used as the upper mold and the lower mold to 75°C higher than the melting temperature of the brazing material;

[0071] b: Quickly place the installation part of the copper bar base 1 and the welding part of the lead workpiece 2, which have been positioned together by the positioning structure, between the two resistance blocks, so that the two resistance blocks are connected to the installation part and the two resistance blocks at a pressure of 0.25MPa The welding part is fit;

[0072] c: Continue to pass 700A current to the resistance block, and weld for 9s to fully melt the solder;

[0073] d: After disconnecting the current, keep the pressure for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com