A kind of single crystal nickel cobalt lithium manganate precursor and its preparation method and application

A technology of nickel-cobalt-lithium-manganese-oxide and its precursors, which is applied in the field of single-crystal nickel-cobalt-lithium-manganese oxide precursors and its preparation, can solve the problems of easy breakage, uncontrollable shape, and many side reactions at the interface, so as to ensure uniformity , easy to disperse by ball milling, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

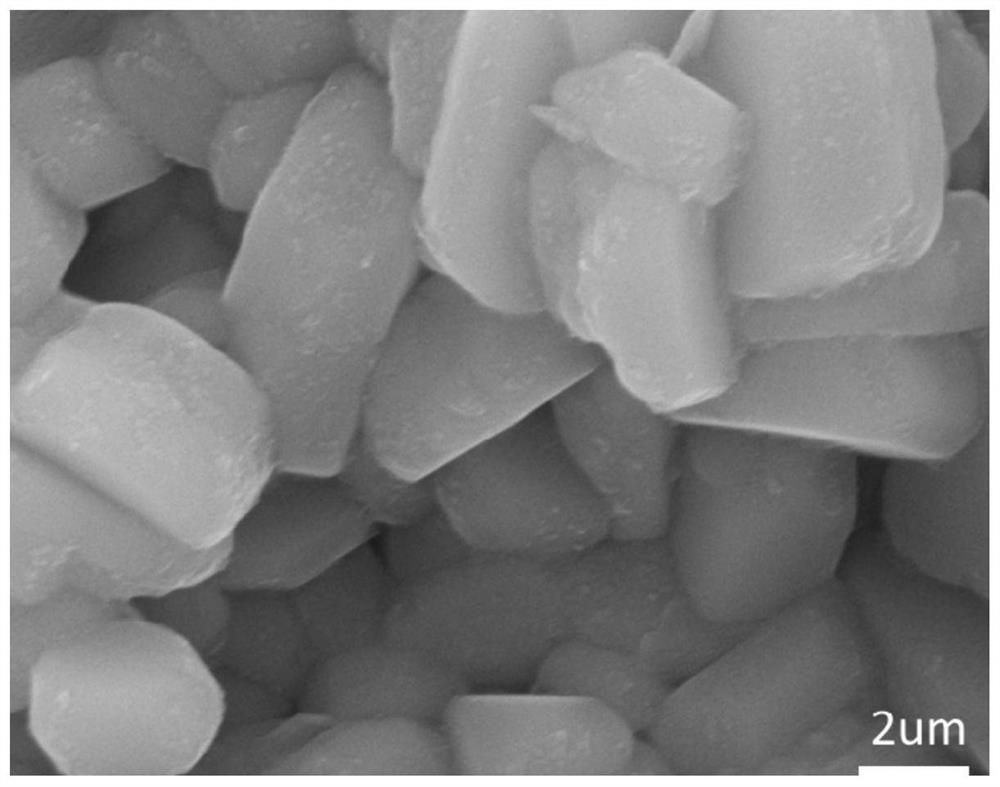

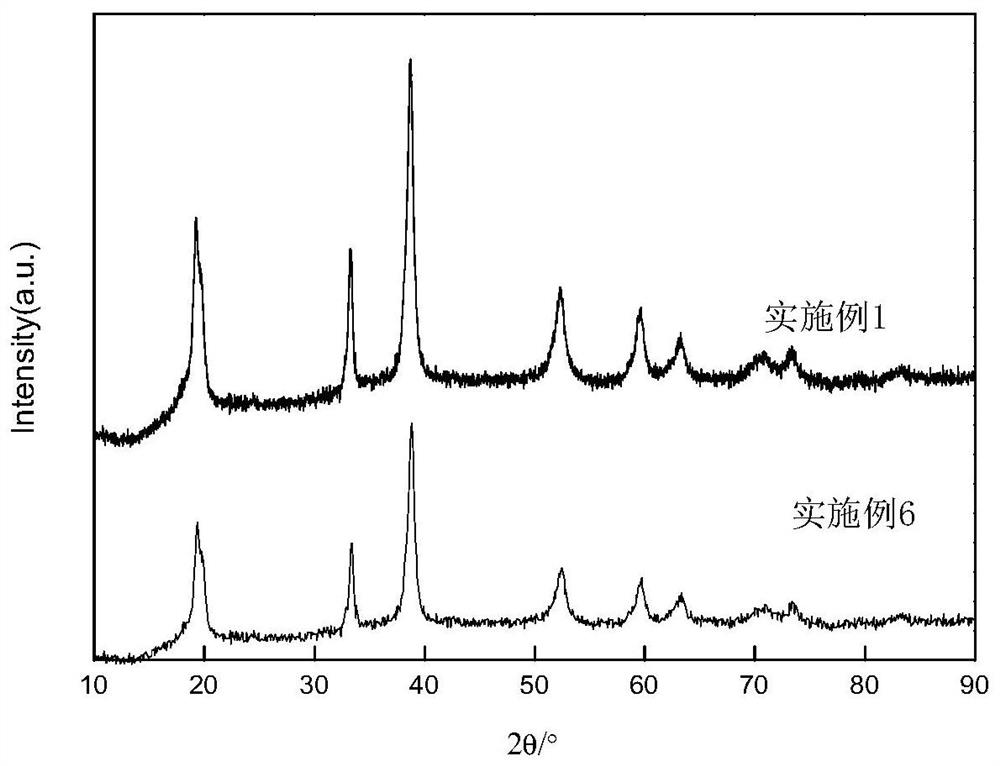

[0049] Weigh Ni(NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 and Al(NO 3 ) 3 Dissolved in deionized water to form a 0.1mol / L mixed salt solution, mixed with 0.1mol / L Na 2 CO 3 The solution is input into the reactor (2L) of dispersing PVP (concentration is 0.01mol / L) concurrently, wherein, mixed salt solution, Na 2 CO 3 The feed flow rate of the solution was 1mL / min, the dispersion rate of PVP was 1mL / min, the reaction temperature was 30°C, and the stirring intensity was controlled at 300r / min. To the end of the reaction mixed salt solution, Na 2 CO 3 The volume of solution and PVP is close to 1:1:1) After centrifugation, washing and drying, Ni 0.5 co 0.2 mn 0.2 Al 0.1 CO 3 precursor material. The particle size of the prepared precursor material D 50 The particle size is 6um, the shape is uniformly dispersed nanosheets, the primary particle size is about 2um single crystal, the crystallinity is good, the scanning electron microscope picture is as follows figure 1 As ...

Embodiment 2

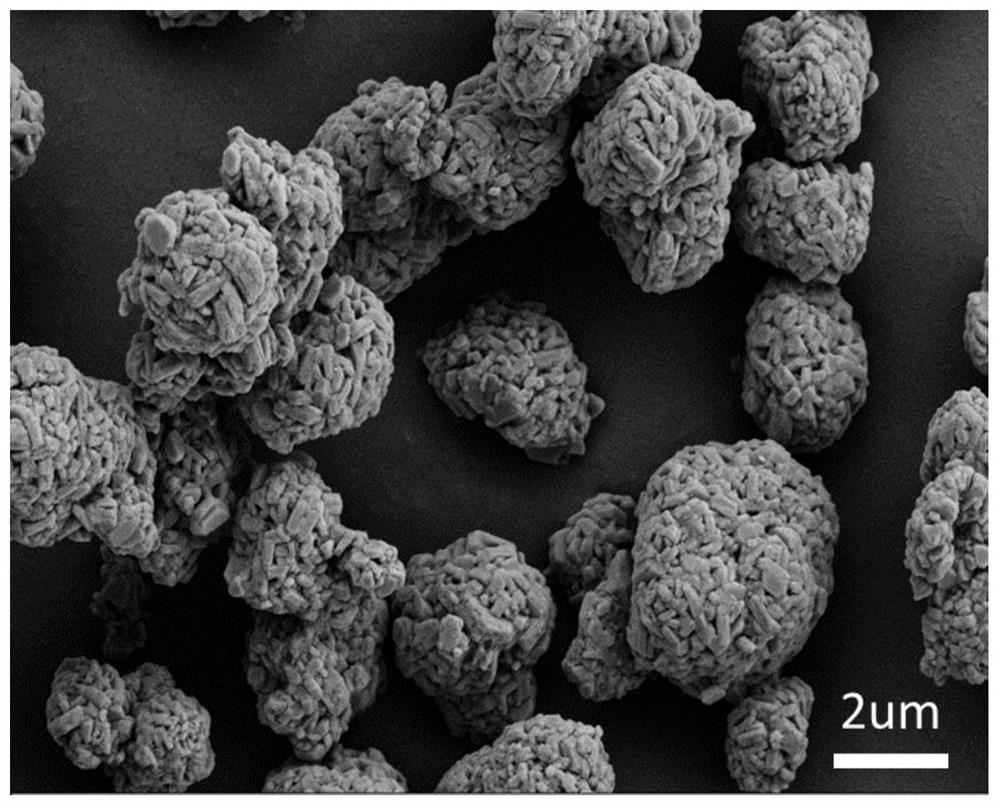

[0051] Weigh NiSO according to the Ni, Co, Mn molar ratio of 0.6:0.2:0.2 4 、CoSO 4 , MnSO 4 Dissolve in deionized water to form a 1mol / L mixed salt solution, and mix with 2mol / L NaHCO 3 The solution is input into the reaction kettle (2L) of dispersing PEG-400 (concentration is 0.1mol / L) in parallel flow, wherein, mixed salt solution, NaHCO 3 The feed flow rate of the solution is 1mL / min, the dispersion rate of PEG-400 is 1mL / min, the reaction temperature is 80°C, the stirring intensity is controlled at 800r / min, the reaction liquid overflows naturally after the reactor is full, and the reaction is stirred for 30 hours After (to the end of the reaction mixed salt solution, NaHCO 3 The volume of the solution and PEG-400 is close to 1:1:1) After centrifugation, washing and drying, Ni 0.6 co 0.2 mn 0.2 (HCO 3 ) 2 precursor material. The particle size of the prepared precursor material D 50 It is 10um, the shape is uniformly dispersed hexagonal bricks, and the crystallini...

Embodiment 3

[0053] According to Ni, Co, Mn, V molar ratio is 0.75:0.1:0.1:0.05: Weigh NiC 2 o 4 、CoC 2 o 4 , MnC 2 o 4 , NH 4 VO 3 Dissolved in deionized water to form a 5mol / L mixed salt solution, mixed with 5mol / L (NH 4 )2 CO 3 The solution is input into the reactor (2L) of dispersing op-10 (concentration is 0.05mol / L) in parallel flow, wherein, mixed salt solution, (NH 4 ) 2 CO 3 The feed flow rate of the solution is 1mL / min, the dispersion rate of op-10 is 1mL / min, the reaction temperature is 50°C, the stirring intensity is controlled at 500r / min, the reaction liquid overflows naturally after the reactor is full, and the reaction is stirred for 20 hours After (to the end of the reaction mixed salt solution, (NH 4 ) 2 CO 3 The volume of solution and op-10 is close to 1:1:1) After centrifugation, washing and drying, Ni 0.75 co 0.1 mn 0.1 V 0.05 CO 3 precursor material. The particle size of the prepared precursor material D 50 It is 15um, and the shape is uniformly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser granularity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com