Microwave preparation method of high-quality aluminum nitride powder

A high-quality technology of aluminum nitride, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as difficult production and application, incomplete reaction, complex equipment, etc., achieve short holding time, high production efficiency, The effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

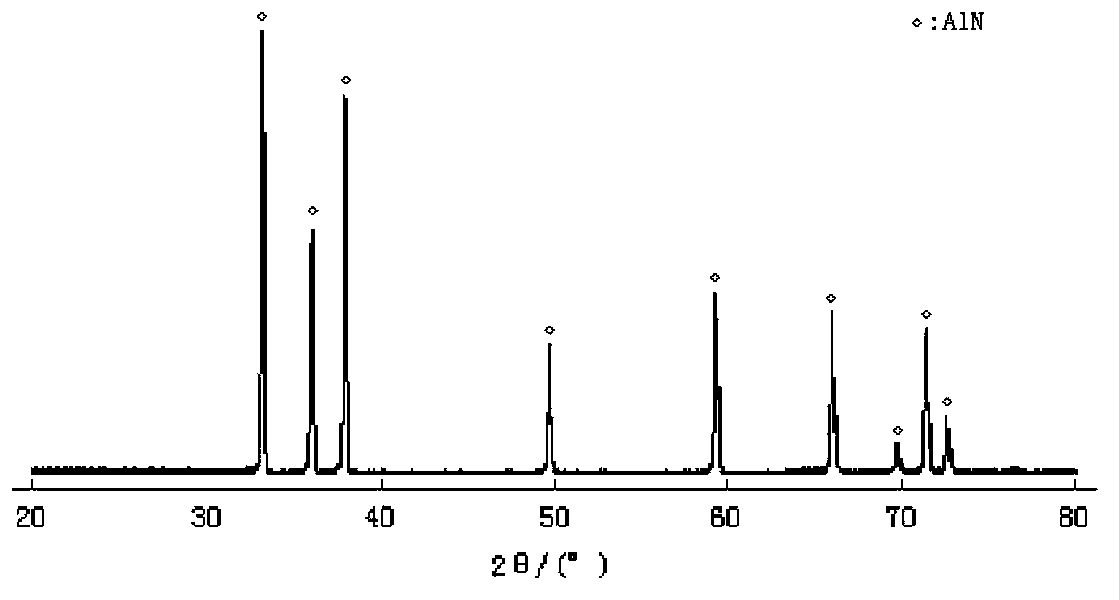

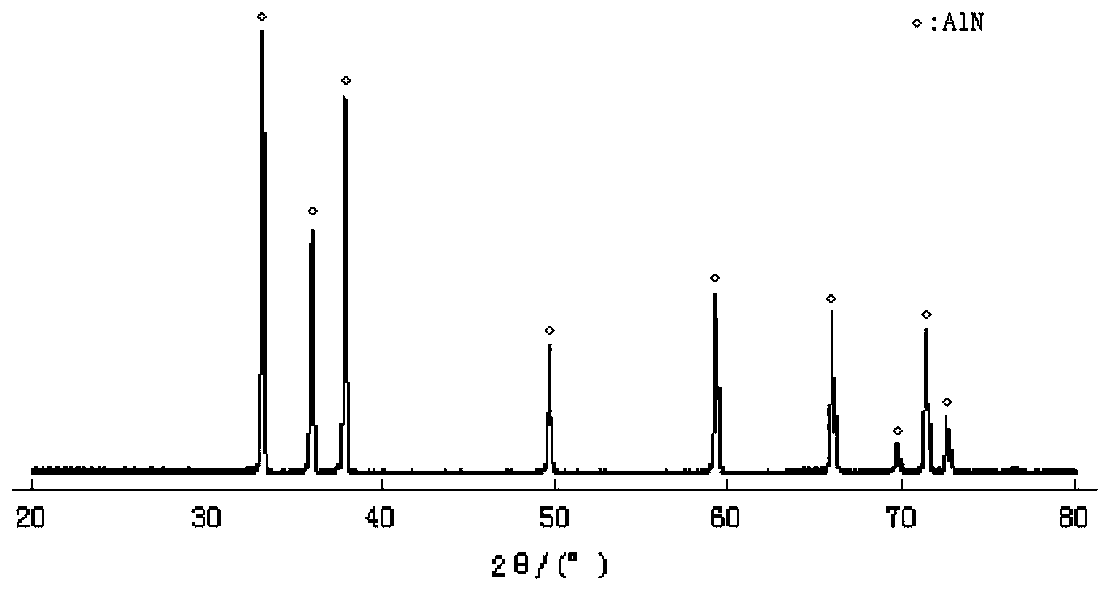

Image

Examples

Embodiment 1

[0030] Using γ-Al with a particle size of 4.4 μm 2 o 3 Powder and metallurgical-grade high-purity carbon black with a particle size of 1 μm are used as raw materials, and the metallurgical-grade high-purity carbon black and γ-Al are weighed according to the C / Al molar ratio of 3.57:1 2 o 3 Powder, then add calcium carbonate according to the Al / Ca molar ratio of 100:3, mix and ball mill with water for 8 hours, dry and sieve to obtain the raw material to be synthesized. The prepared raw materials were placed in the microwave synthesis reaction chamber of an intermittent industrial microwave oven for microwave synthesis, and high-purity nitrogen gas was introduced, the pressure was normal pressure, the heating rate was 10°C / min, the synthesis temperature was 1420°C, and the temperature was kept for 2 hours. The obtained synthesis The product is heat-treated at 650°C in the air and kept for 10 hours, and the product obtained after cooling is the finished aluminum nitride powder....

Embodiment 2

[0032] Dissolve analytically pure glucose in an aqueous solution of analytically pure aluminum nitrate and calcium carbonate at a C / Al molar ratio of 4.2:1, and the Al / Ca molar ratio of aluminum nitrate and calcium carbonate is 100:5. Then the prepared solution was stirred while heating at 200°C, and finally a fluffy powder was obtained as the precursor of the reaction. The obtained precursor was placed in the microwave synthesis reaction chamber of a continuous industrial microwave oven for microwave synthesis, high-purity nitrogen gas was introduced, the pressure was normal pressure, the heating rate was 8°C / min, the synthesis temperature was 1350°C, and the temperature was kept for 5 hours. The obtained composite is heat-treated at 680°C in the air and kept for 2 hours, and the obtained product is finished aluminum nitride powder after cooling. Finished product color is off-white. After determination, the finished product of aluminum nitride powder contains 33.0% nitrogen,...

Embodiment 3

[0034]Use analytically pure aluminum nitrate and metallurgical-grade high-purity carbon black with a particle size of 0.5 μm as raw materials, weigh metallurgical-grade high-purity carbon black and aluminum nitrate respectively according to the molar ratio of C / Al of 4.44:1, and then weigh them according to the molar ratio of Al / Ca Add calcium carbonate at a ratio of 100:2, mix and ball mill with water for 5 hours, and obtain a uniformly mixed reaction precursor after drying. The prepared precursor was placed in the microwave synthesis reaction chamber of an intermittent industrial microwave oven for microwave synthesis, and N 2 +5%H 2 The mixed gas, the pressure is normal pressure, the heating rate is 15 ° C / min, the synthesis temperature is 1500 ° C, and the temperature is kept for 0.5 hours. powder. Finished product color is off-white. After measurement, the finished aluminum nitride powder contains 33.2% nitrogen, 1.0% oxygen, 0.2% carbon, and a particle size of 0.7 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com