Synthesis process of a highly wear-resistant artificial diamond flake catalyst

A technology of synthetic diamond and synthesis process, which is applied in the field of high wear-resistant synthetic diamond sheet catalyst synthesis process, which can solve the problems of short tool life, limited raw material shape, large single crystal stress, etc., and achieve sharp edges and high magnetic susceptibility. Grinding, sharp edges and low magnetic susceptibility, the effect of temperature-pressure field improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

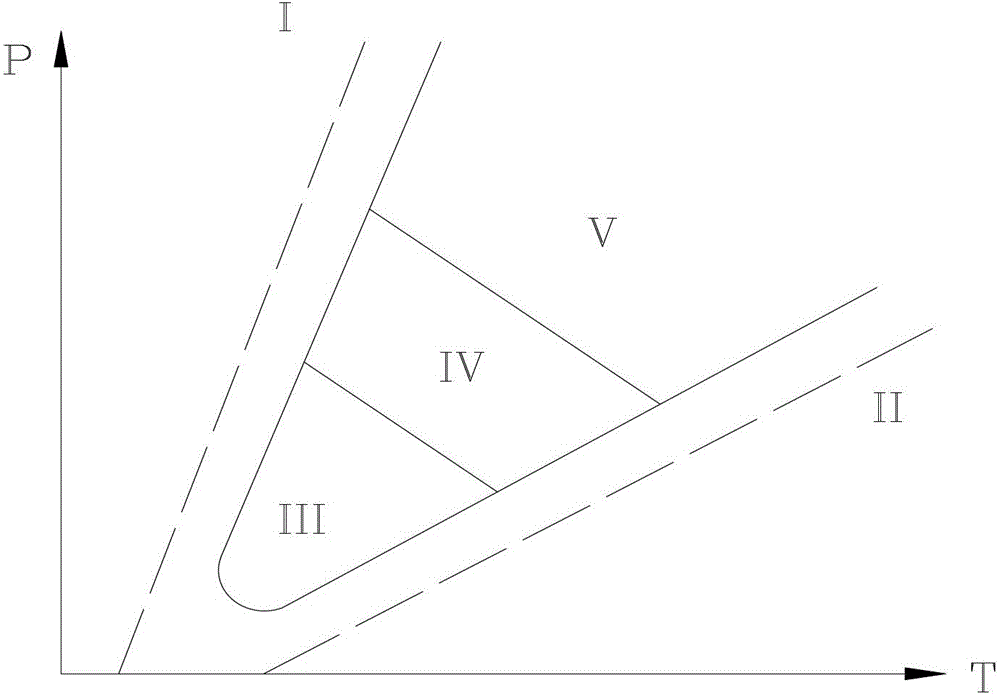

[0017] In the metal-carbon P-T phase diagram, such as figure 1 , I line is the metal-C mutual melting line, II line is the graphite-diamond phase equilibrium line in the "V" shape area between I-II, III area is the excellent crystal area, low temperature and low pressure, suitable for growing high-quality diamond. Zone IV is a crystal-rich zone with faster crystal growth rate, more inclusions, and finer grain size. Zone V is an abrasive-grade diamond generation zone with a lot of nucleation, fast growth, incomplete structure, irregular shape, and fine grain size.

[0018] Since the excellent crystal area is located at the bottom of the "V"-shaped area, it is prone to corrosion when it is biased towards II, and the stress increases sharply.

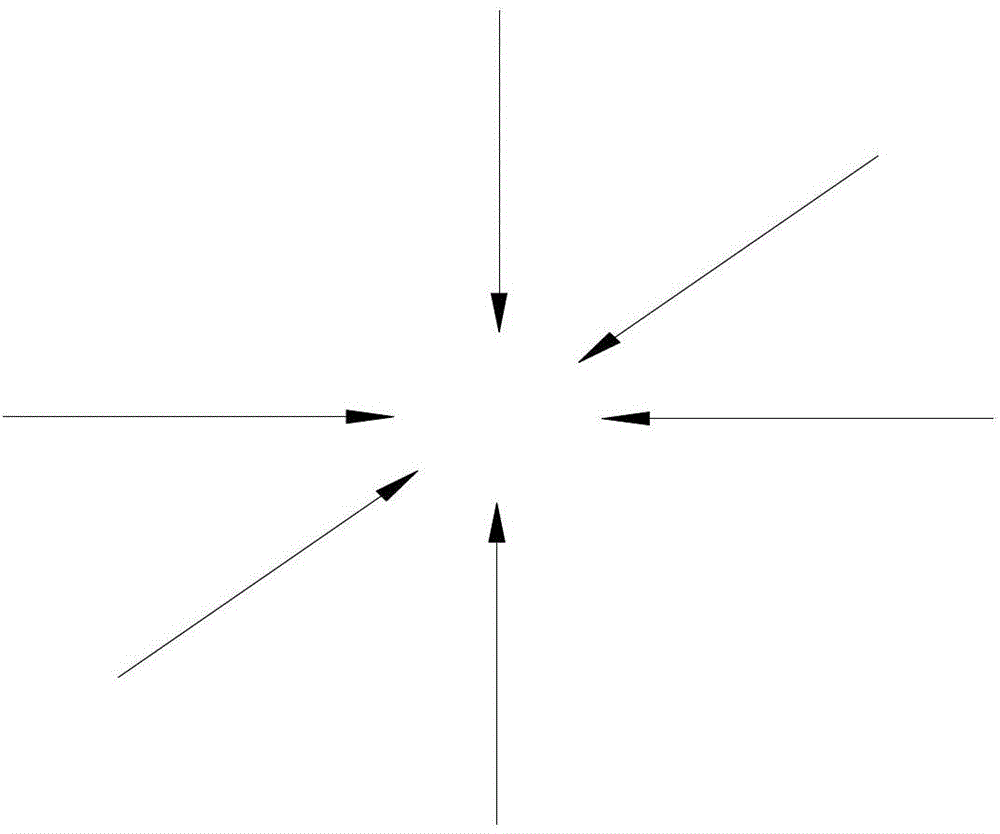

[0019] 1. The equipment can precisely control P and T,

[0020] 2. Minimize the pressure gradient and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com