Temperature stabilizing and humidity reducing dense flue-cured tobacco curing method

A technology of intensive curing and dense curing room, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of the influence of tobacco leaf curing quality, large loss of tobacco leaf curing, and easy rise and fall of temperature, so as to prolong the synthesis of aroma Time, increase the yellow smoke rate of baking, and the effect of convenient temperature control and drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

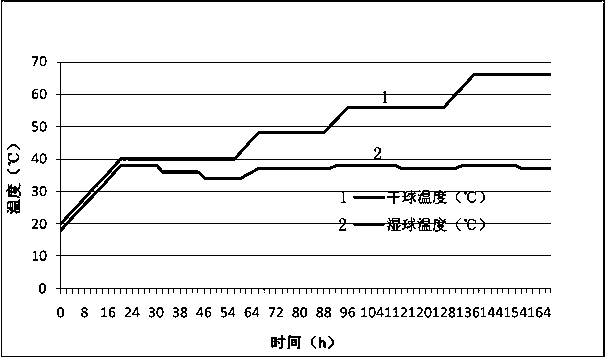

Method used

Image

Examples

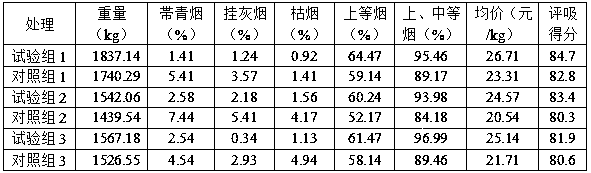

Embodiment 1

[0049] 1. Variety of flue-cured tobacco: roast mature tobacco leaves of k326 variety in Yuxi City;

[0050] 2. Overhaul the intensive drying room to ensure that the mechanical equipment is operating normally, the wall is not leaking, and the humidity temperature sensor is working normally; the dense drying room used is an airflow rising dense drying room;

[0051] 3. Only one variety can be baked in one furnace;

[0052] 4. Hanging of temperature and humidity sensors: one humidity sensor is hung on the top floor of the barn, and the other is hung on the bottom floor of the barn. The temperature sensing head is as low as 5cm above the leaf tip.

[0053] 5. Requirements for weaving smoke: the weaving smoke density is 7kg / rod, and the reasonable smoke density is 49kg / m 3 , so that evenly, evenly loaded. The principle of smoke filling is to install one rod less than the smoke density in the low temperature area, and install one more rod in the high temperature area relative to ...

Embodiment 2

[0070] 1. Toast the mature tobacco leaves of krk26 variety in Lijiang City;

[0071] 2. Overhaul the intensive drying room to ensure that the mechanical equipment is operating normally, the wall is not leaking, and the humidity temperature sensor is working normally; the dense drying room used is an airflow descending dense drying room;

[0072] 3. Only one variety can be baked in one furnace;

[0073] 4. Hanging of temperature and humidity sensors: one humidity sensor is hung on the top floor of the barn, and the other is hung on the bottom floor of the barn. The temperature sensing head is as low as 10cm above the leaf tip.

[0074] 5. Requirements for weaving smoke: weaving smoke density 8kg / rod, reasonable smoke density 48kg / m 3 , so that evenly, evenly loaded. Note: The low-temperature area should be packed thinly, and the high-temperature area should be packed densely. The principle of smoke filling is that the low-temperature area should be filled with 2 rods less th...

Embodiment 3

[0089] 1. Roast the mature tobacco leaves of the Honghua Dajinyuan variety in Dali Prefecture;

[0090] 2. Overhaul the intensive drying room to ensure that the mechanical equipment is operating normally, the wall is not leaking, and the humidity temperature sensor is working normally; the dense drying room used is an airflow descending dense drying room;

[0091] 3. Only one variety can be baked in one furnace;

[0092] 4. Hanging of temperature and humidity sensors: one humidity sensor is hung on the top floor of the barn, and the other is hung on the bottom floor of the barn. The temperature sensing head is as low as 8cm above the leaf tip.

[0093] 5. Requirements for weaving smoke: the weaving smoke density is 7.14kg / rod, and the reasonable smoke density is 50kg / m 3 , so that evenly, evenly loaded. Note: The low temperature area is properly packed with thinner, and the high temperature area is properly packed with dense.

[0094] 6. This method is divided into three b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com