Microwave synthesis method for aluminum nitride powder

A microwave synthesis, aluminum nitride powder technology, applied in nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of incomplete reaction, low efficiency, complex equipment and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

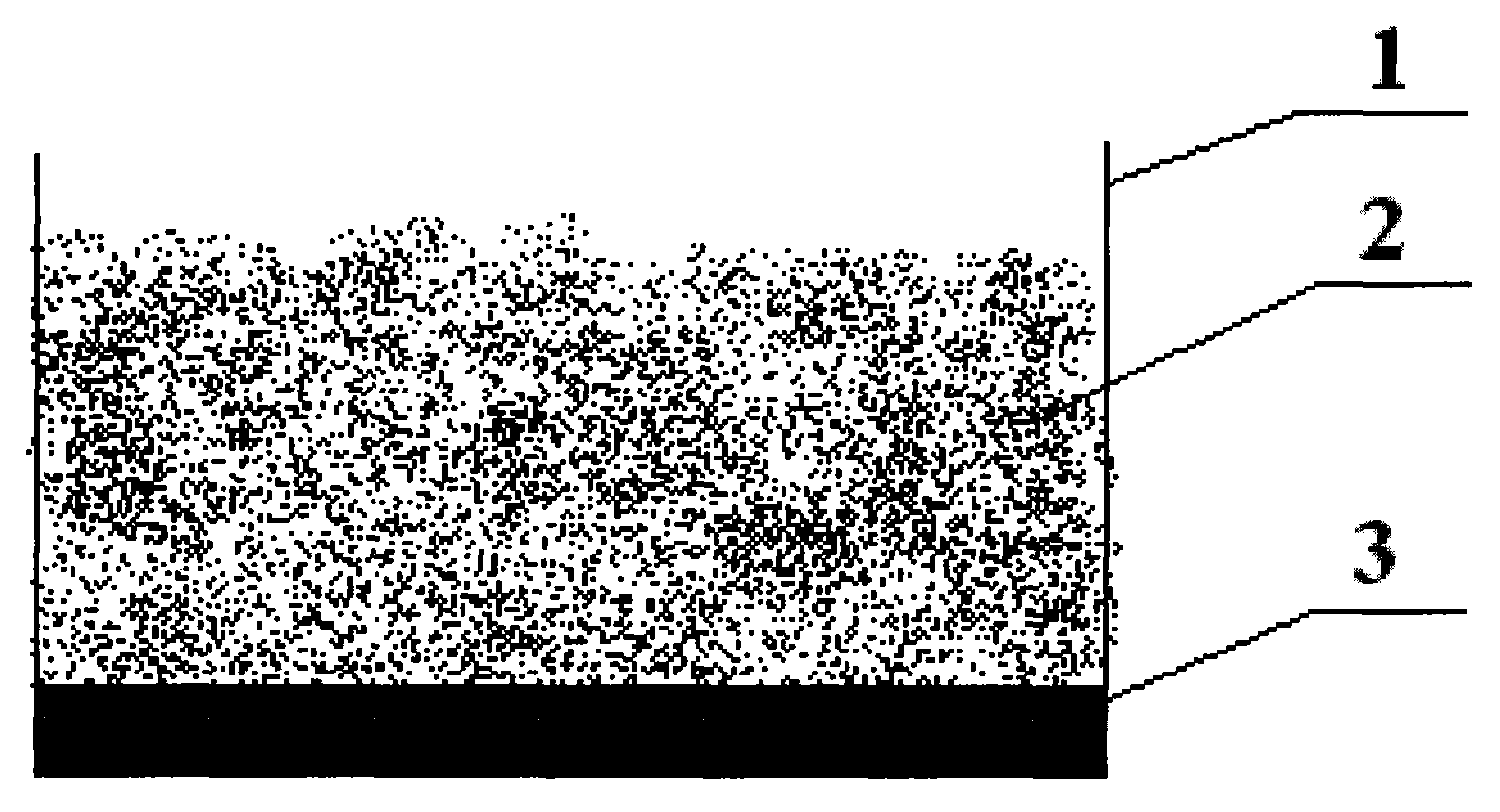

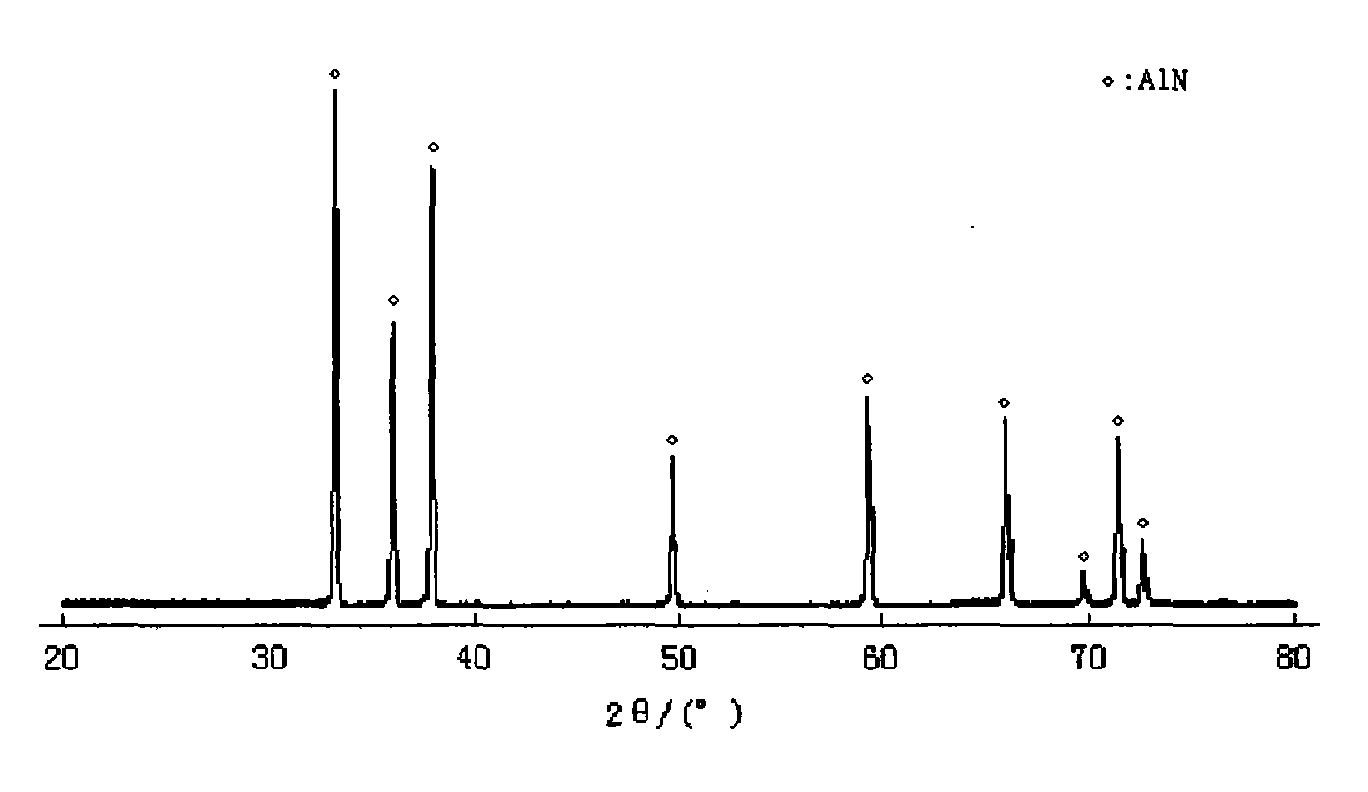

[0023] Embodiment 1: adopt the aluminum powder that particle size is 504 μm to make raw material, after 100g aluminum powder is mixed with 3g ammonium fluoride, as figure 1 Shown inside a sagger. The sagger was placed in the microwave synthesis reaction chamber of an intermittent industrial microwave oven for microwave synthesis, and the microwave frequency was 2.45 GHz. Introduce high-purity nitrogen, the pressure is normal pressure, the synthesis temperature is 1050 ° C, and the temperature is kept for 0.5 hours. After cooling, the obtained composition is the finished aluminum nitride. Finished product color is off-white. After determination, the finished aluminum nitride product contains 33.4% nitrogen, and the XRD analysis phase structure is AlN, such as figure 2 shown.

Embodiment 2

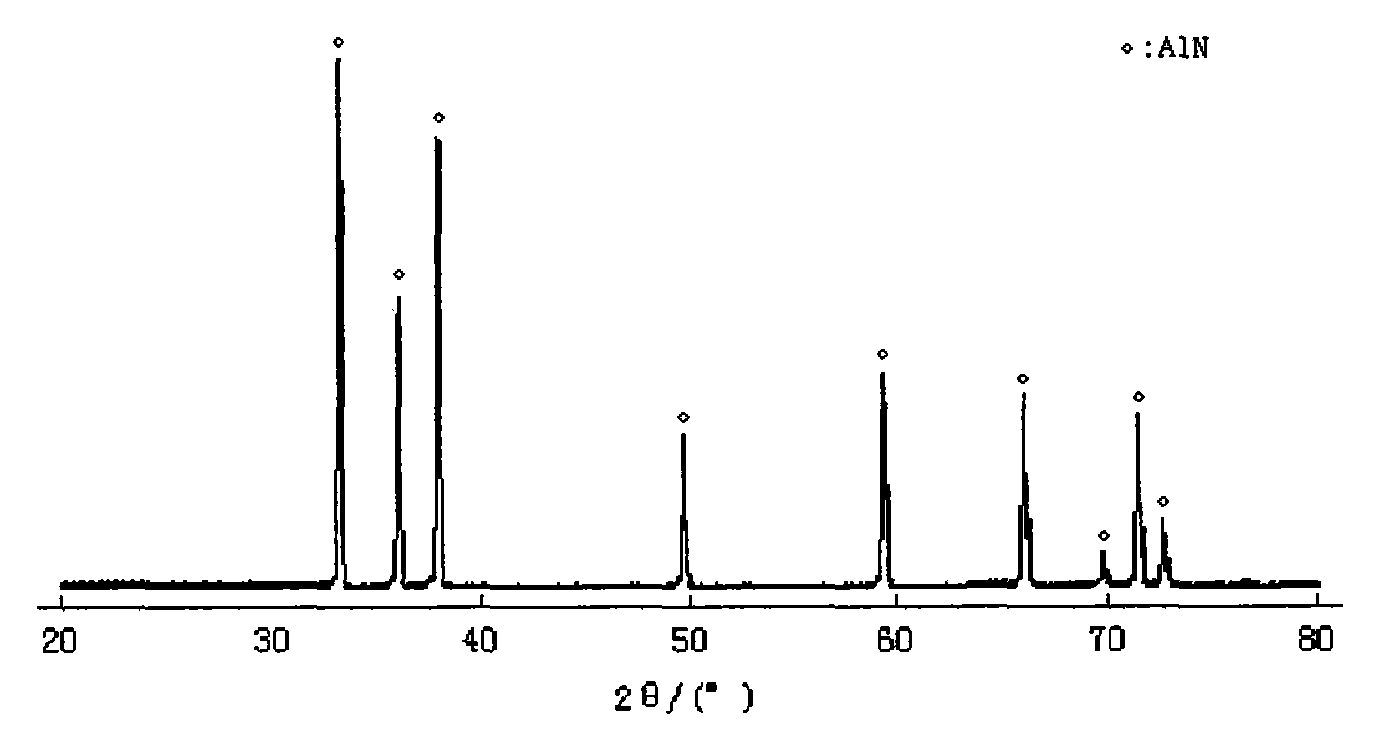

[0024] Embodiment 2: After mixing 1000g aluminum powder with 30g ammonium bicarbonate, as figure 1 Shown inside a sagger. The sagger was placed in the reaction chamber of a continuous industrial microwave oven for microwave synthesis, and the microwave frequency was 2.45 GHz. Introduce high-purity nitrogen, the pressure is normal pressure, the synthesis temperature is 1000°C, and the temperature is kept for 0.5 hours. After cooling, the obtained composition is the finished aluminum nitride. Finished product color is off-white. After determination, the finished aluminum nitride product contains 32.5% nitrogen, and the XRD analysis phase structure is AlN, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com