A kind of preparation method of aluminum-doped cobalt hydroxide applied to high-voltage ICO coating material

A coating material, cobalt hydroxide technology, applied in the direction of cobalt oxide/cobalt hydroxide, circuit, positive electrode, etc., can solve the problem of easy particle agglomeration, difficulty in dispersing nano-scale cobalt hydroxide particles, poor fluidity of slurry, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

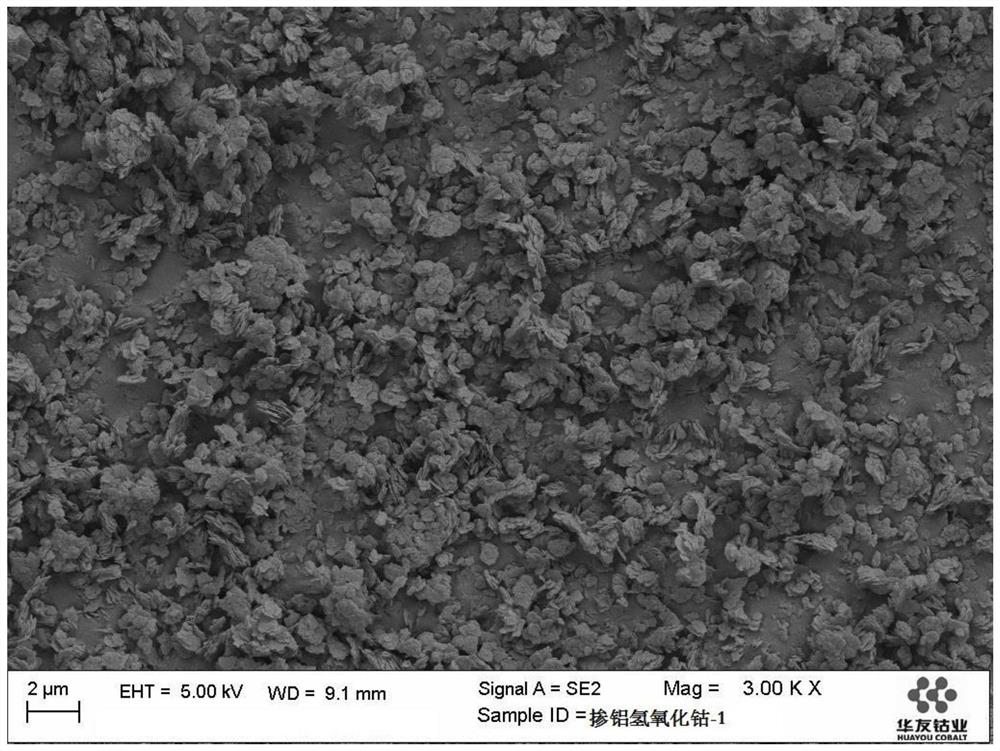

Embodiment 1

[0021] 1. Prepare 80g / L cobalt chloride solution, add to every 1m 3 Add 4.614kg of aluminum chloride to the cobalt liquid and stir evenly;

[0022] 2. Dilute the industrial liquid caustic soda with water to prepare a sodium hydroxide solution with a concentration of 40g / L;

[0023] 3. Add 3m into the reactor 3 Base with pure water, and add sodium borohydride with 1% Co quality; start stirring, and add the cobalt-aluminum mixed salt solution and sodium hydroxide solution in steps 1 and 2 at the same time at room temperature, and the flow rate of the cobalt-aluminum mixed salt solution is 1000L / h, the pH of the reaction process is strictly controlled by the flow of sodium hydroxide solution to be above 12.0, and the reaction time of feeding is controlled to 8h. After 8h, stop feeding and raise the temperature of the reaction system to 40°C. After the temperature reaches the requirement, stir for 0.2h to form and disperse the particles open;

[0024] 4. The synthesized alumin...

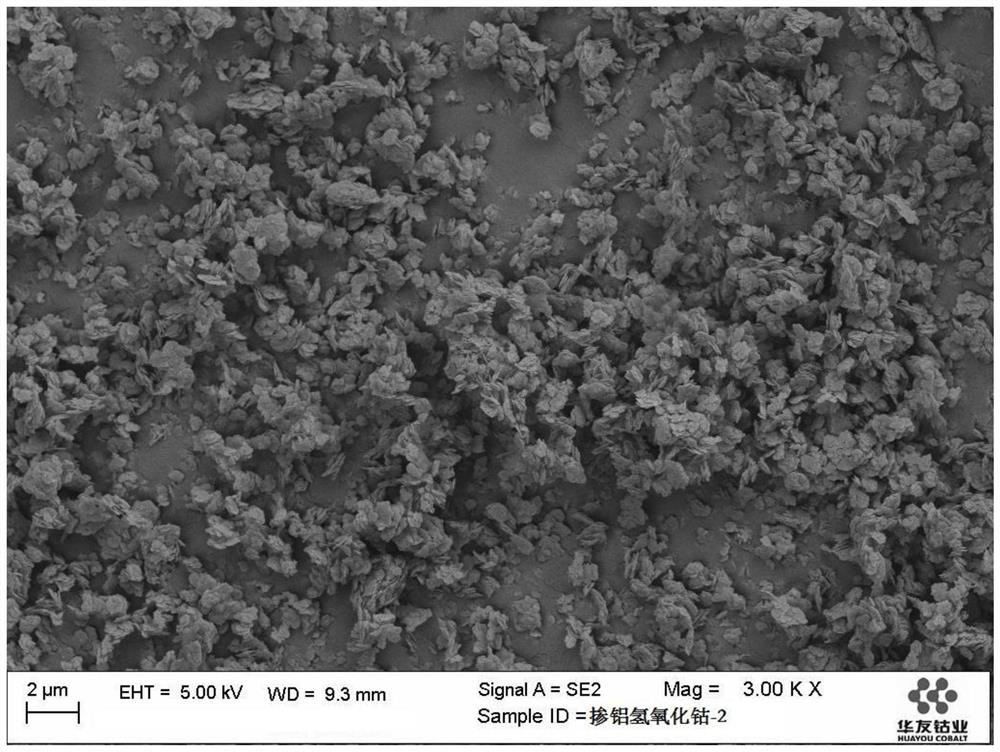

Embodiment 2

[0027] 1. Prepare 120g / L cobalt sulfate solution, 3 Add 16.845kg of aluminum sulfate to the cobalt solution and stir evenly;

[0028] 2. Dilute the industrial liquid caustic soda with water to prepare a sodium hydroxide solution with a concentration of 60g / L;

[0029] 3. Add 3.5m 3 Base with pure water, and add acetone oxime with 1.5% Co quality; start stirring, and add the cobalt-aluminum mixed salt solution and sodium hydroxide solution in steps 1 and 2 at the same time at room temperature, and the flow rate of the cobalt-aluminum mixed salt solution is 1500L / h, strictly control the pH of the reaction process through the flow of sodium hydroxide solution to be above 12.0, and control the feeding reaction time to 5.5h. After 5.5h, stop feeding and raise the temperature of the reaction system to 50°C. After the temperature reaches the requirement, stir for 0.3h to let the particles form and scattered;

[0030] 4. The synthesized aluminum-doped cobalt hydroxide is press-fil...

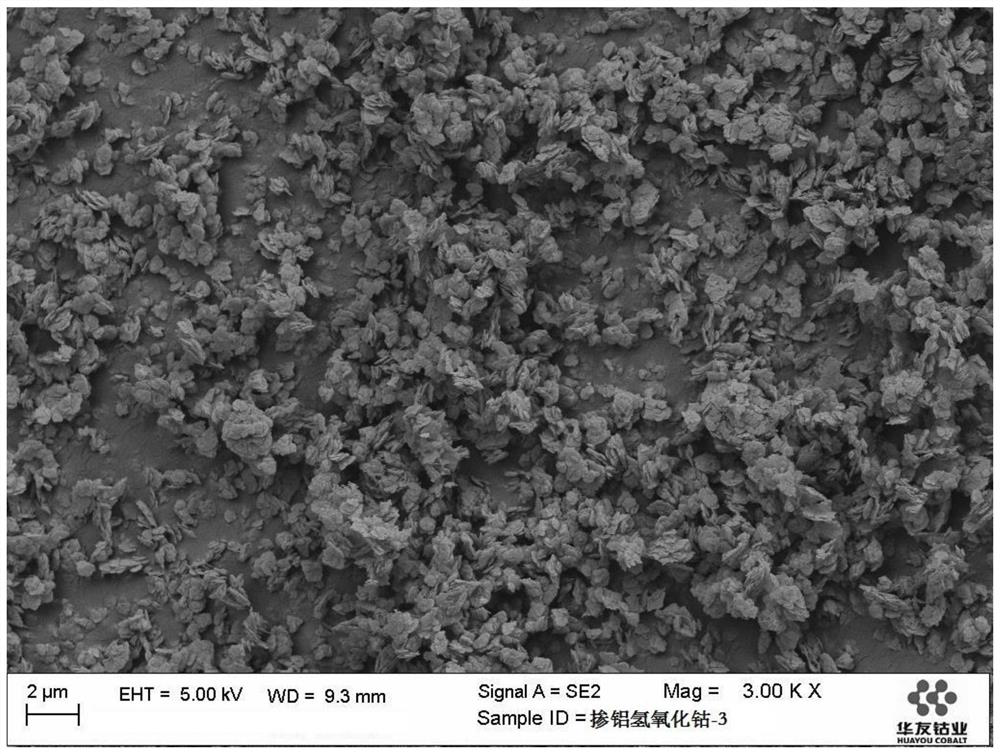

Embodiment 3

[0033] 1. Prepare 160g / L cobalt nitrate solution, add to every 1m 3 Add 22.769kg of aluminum nitrate to the cobalt solution and stir evenly;

[0034] 2. Dilute the industrial liquid caustic soda with water to prepare a sodium hydroxide solution with a concentration of 80g / L;

[0035] 3. Add 4m into the reactor 3 Base with pure water, and add hydrazine hydrate with 2% Co mass; start stirring, and add the cobalt-aluminum mixed salt solution and sodium hydroxide solution in steps 1 and 2 at the same time at room temperature, and the flow rate of the cobalt-aluminum mixed salt solution is 2000L / h. Strictly control the pH of the reaction process through the flow of sodium hydroxide solution to be above 12.0, and the reaction time of feeding is controlled to 4h. After 4h, stop feeding and raise the temperature of the reaction system to 60°C. After the temperature reaches the requirement, stir for 0.4h to form and disperse the particles. ;

[0036] 4. The synthesized aluminum-dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com