Matrix for machine-transplanted rice seedlings and preparation method thereof

A rice machine transplanting and substrate technology, which is applied to fertilizer mixtures, fertilizing devices, applications, etc., can solve problems such as inability to meet requirements, large amount of vegetable soil or paddy soil ponds, impact on planting crops, etc., and achieves low cost. Strong, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 78.9 kg of yellow mud, 11.2 kg of refined organic fertilizer, 0.5 kg of urea, 2.4 kg of superphosphate, 0.6 kg of potassium chloride, and 6.4 kg of rice husk ash; ), the water content should be 10-15%; the refined organic fertilizer is a refined organic fertilizer containing more than 30% organic matter; the above raw materials should be weighed as much as possible, that is, the stubble, weeds, Gravel and other pollutants;

[0039] Crush: crush and sieve the yellow mud; the aperture of the sieve is 4-8mm, and generally a sieve with a 5mm aperture is used;

[0040] Mixing: Mix the above raw materials and stir evenly;

[0041] Maturation: Heap the well-stirred materials for 15-40 days (about 20 days in summer and about 40 days in early spring, adjust the heaping time according to the temperature), and get the stuffy heap matrix;

[0042] Disinfection: 6 to 8 days before sowing, take 5 to 6 grams of Dixon, 90 to 110 times the weight of Dixon water (that is, 5 grams...

Embodiment 2-11

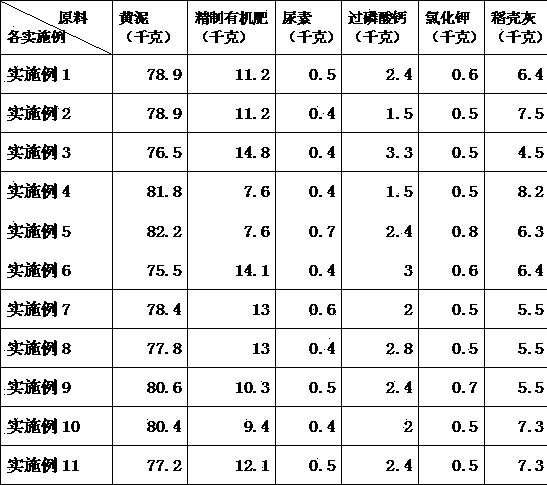

[0047] The raw material kind that embodiment 2-11 uses and preparation method are identical with embodiment 1, only the amount of the raw material that adopts is different from embodiment 1; Table 2 below has shown the concrete that embodiment 1-11 uses raw materials and quality;

[0048] Table 2

[0049]

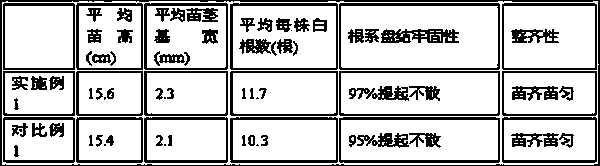

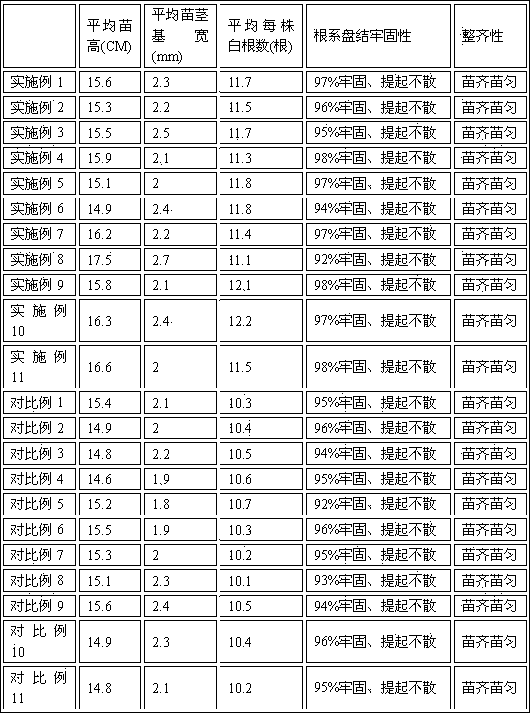

[0050] Adopt the same method as embodiment 1 for the substrate of rice seedling transplanting that each embodiment obtains to make seedling contrast experiment, obtain the statistical data of each embodiment and comparative example as follows (table 3):

[0051] table 3

[0052]

[0053] As can be seen from the above table 3: the substrate of the rice raising machine transplanting seedlings of the various embodiments of the present invention can fully reach the effect of conventionally used vegetable soil, paddy field soil and pond mud mixture seedling raising, and also slightly better than the conventionally used vegetable soil. Soil, paddy field soil and the effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com