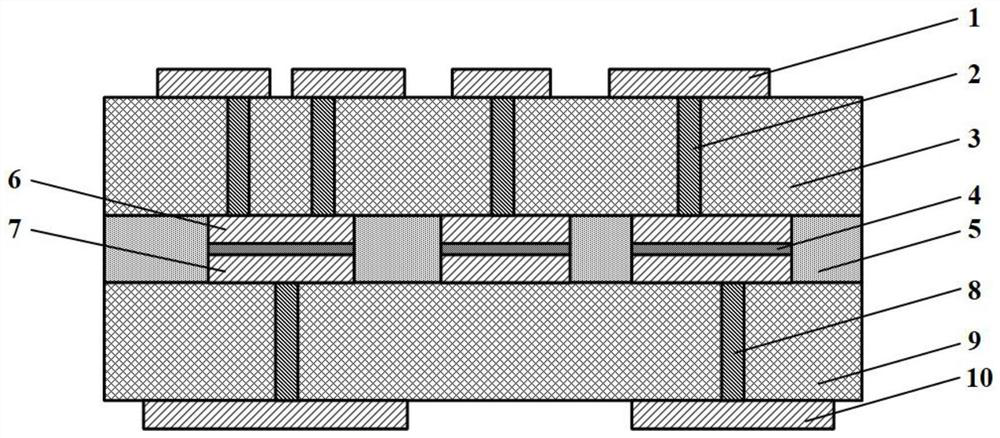

Preparation method of multilayer ceramic circuit board

A technology of multi-layer ceramics and circuit boards, applied in multi-layer circuit manufacturing, printed circuit manufacturing, circuits, etc., can solve the problems of low wiring accuracy, wiring accuracy, insufficient yield, low yield, etc., to reduce shrinkage differences, The effect of high yield and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the metal solder is SnAgCu solder paste.

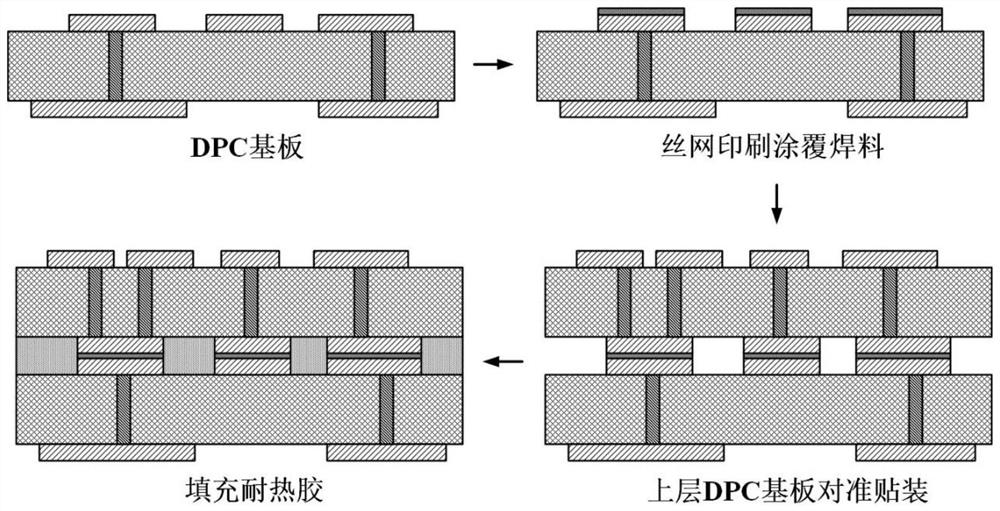

[0039] In this embodiment, realizing the bonding between the DPC ceramic substrate 3 and the DPC ceramic substrate 9 includes the following steps:

[0040] 1) Degreasing, decontaminating and drying the ceramic substrate 3 and the ceramic substrate 9 and their metal layers;

[0041] 2) Coating the SnAgCu solder paste onto the metal layer 7 of the ceramic substrate 9 by screen printing, with a thickness of 40 μm;

[0042] 3) Align the ceramic substrate 3 with the metal layer on the ceramic substrate 9, adopt a solder bonding process, and make SnAgCu under the process conditions of a maximum bonding temperature of 280 ° C, a bonding pressure of 2 MPa, and a bonding time of 15 minutes. The solder is bonded to the substrate, thereby realizing the mechanical connection and electrical interconnection of the two ceramic substrates.

Embodiment 2

[0044] In this embodiment, AuSn solder is selected as the metal solder.

[0045] In this embodiment, realizing the bonding between the DPC ceramic substrate 3 and the DPC ceramic substrate 9 includes the following steps:

[0046] 1) Degreasing, decontaminating and drying the ceramic substrate 3 and the ceramic substrate 9 and their metal layers;

[0047] 2) AuSn solder is deposited on the metal layer 7 of the ceramic substrate 9 by a physical vapor deposition (CVD) process, with a thickness of 3 μm;

[0048] 3) Align the ceramic substrate 3 with the metal layer on the ceramic substrate 9, and use the eutectic bonding process under the conditions of the highest bonding temperature of 320° C., the bonding pressure of 10 MPa, and the bonding time of 15 minutes. The AuSn solder is bonded to the substrate, thereby realizing the mechanical connection and electrical interconnection of the two-layer ceramic substrate.

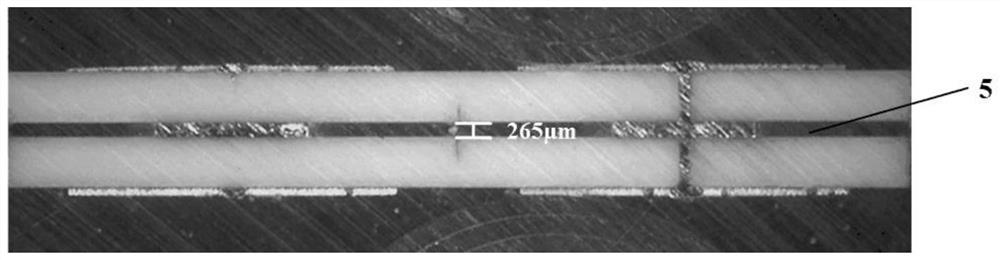

[0049] In the invention of the multi-layer ceramic circuit boar...

Embodiment 3

[0052] In this embodiment, PI polyimide is selected as the high temperature resistant insulating glue. PI glue is a yellow transparent liquid at room temperature, with a viscosity of 30-35Pa s and a thermal expansion coefficient of 3.6×10 -5 / °C.

[0053] In this embodiment, after the ceramic substrate 3 and the ceramic substrate 9 are bonded using SnAgCu solder, the process of filling the heat-resistant glue between the substrates 3 and 9 includes the following steps:

[0054] 1) Use a syringe to pick up the heat-resistant glue and fill it along the edge of the gap between the ceramic substrate layers. The filling method of the syringe is unilateral and unidirectional "I" extrusion;

[0055] 2) Due to the high viscosity of PI glue, lay the substrate flat, use a vacuum pump to pump air at the other end, and fill the entire interlayer with heat-resistant glue through vacuum adsorption;

[0056] 3) According to the processing process, the temperature is raised to 80°C, 120°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com