Preparation method of single-layer ordered silicon dioxide nanosphere array

A technology of silicon dioxide and nanospheres, which is applied in the field of nanostructure preparation, can solve problems such as the irregular arrangement of nanosphere mask layers, and achieve the effects of easy control of process conditions, short cycle time, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

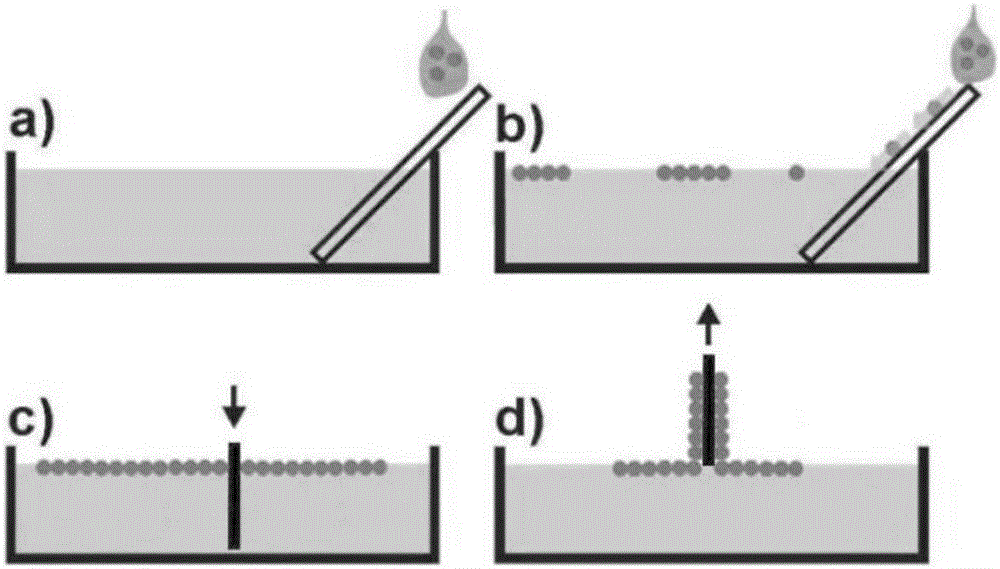

Method used

Image

Examples

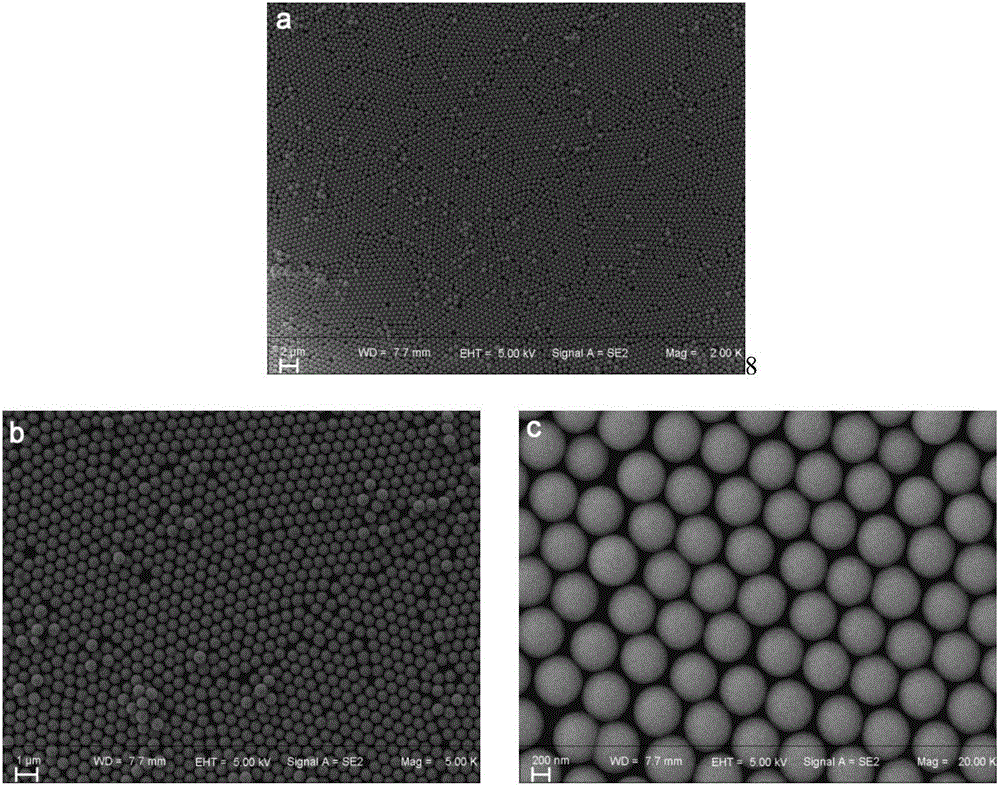

Embodiment 1

[0025] (1) Sapphire cleaning

[0026] The sapphire used is double-polished sapphire with (0001) crystal face purchased on the market, with a thickness of 0.45 mm and a size of 1 cm*1 cm. Put the sapphire chip in deionized water, acetone and absolute ethanol for 20 minutes, respectively, to remove organic impurities on the surface; then wash it with deionized water, and finally put the sapphire substrate in absolute ethanol for later use.

[0027] (2) Cleaning of drainage sheet

[0028] The drainage sheet used is a common glass slide. Put the slides in deionized water, acetone and absolute ethanol in order to ultrasonically clean them for 20 minutes to remove organic impurities on the surface; then wash them with deionized water, and finally put the slides in absolute ethanol for later use.

[0029] (3) Monolayer SiO 2 Preparation of nanospheres

[0030] Purchased SiO with a diameter of 600nm 2 The nanospheres are soaked in absolute ethanol and stored with a density of 0.1...

Embodiment 2

[0033] This embodiment is similar to Embodiment 1, except that the pulling speed in step (3) is 130 μm / min. The prepared SiO 2 The nanosphere arrays are loosely arranged.

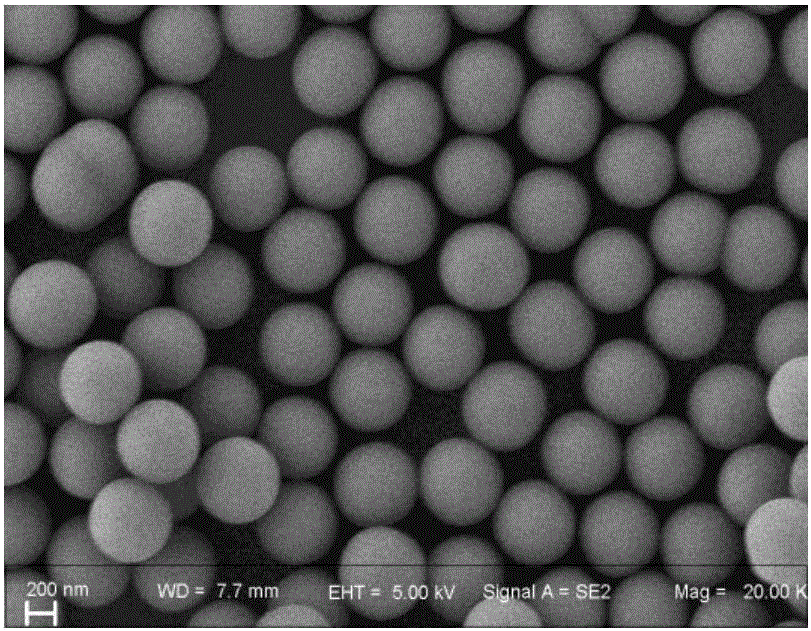

Embodiment 3

[0035] The present embodiment is similar to embodiment 1, and the difference is: in step (3) SiO 2 The original solution of nanosphere absolute ethanol and absolute ethanol were remixed at a ratio of 1:3. Use a pipette to pipette the reconstituted SiO 2 -The absolute ethanol solution is added dropwise on the drainage piece, and it is slowly flowed to the water surface, and the SiO2 in the prepared lifting solution is 2 The nanospheres condense into lumps and spread unevenly, and the Al 2 o 3 The substrate is immersed in the pulling liquid, and is pulled out of the liquid surface vertically and slowly. After the pulling is completed, the Al 2 o 3 multilayer SiO 2 nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com