Nano Ag powder preparation method

A nano-solution technology, applied in the field of powder metallurgy, can solve the problems of uneven particle size distribution of Ag powder, limited popularization and application, and easy particle agglomeration, etc., and achieves the effect of simple operation, low process conditions and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

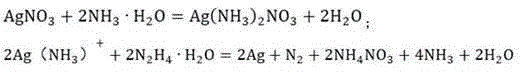

[0016] A preparation method of nano Ag powder, comprising the following steps:

[0017] (1) Preparation: raw materials: silver nitrate, hydrazine hydrate solution, ammonia water, polyvinylpyrrolidone (PVP), compound protective agent; the equipment used in the test is: 79HW-1 constant temperature magnetic stirrer, ZK-82A vacuum drying oven , 80-2 electric centrifuge, KQ-50E ultrasonic cleaner;

[0018] (2) Prepare the mixed solution: Dissolve silver nitrate in distilled water to prepare a 0.01mol / L solution, add a compound protective agent, and stir thoroughly to obtain a mixed solution;

[0019] (3) Prepare the reducing solution: dissolve hydrazine hydrate in distilled water, add ammonia water dropwise to adjust the pH value of the solution to 11, and obtain the reducing solution after fully stirring;

[0020] (4) Oxidation-reduction reaction: put the above-mentioned reducing solution on a high-speed stirrer, heat it to 40°C, and add a mixed solution containing silver nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com