Synthetic method of single-layer porous molybdenum disulfide

A technology of molybdenum disulfide and synthesis method, which is applied in coating, gaseous chemical plating, metal material coating process, etc., and can solve the problems that molybdenum disulfide is difficult, time-consuming, and prone to aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, a kind of synthetic method of monolayer porous molybdenum disulfide, carries out following steps successively:

[0022] (1) Ultrasonic cleaning of the insulating substrate: ultrasonic in acetone, absolute ethanol and deionized water for 5 minutes;

[0023] (2) Weigh 20mg of MoO 3 Powder as the Mo source, and 450mg of sulfur powder as the S source, were poured into different crucibles;

[0024] (3) Dry the cleaned insulating substrate with nitrogen, and MoO 3 The powder is placed in the same crucible, and then placed in the middle high temperature zone of the single temperature zone CVD furnace, the substrate is on the MoO 3 Downstream, place the crucible containing sulfur powder in the low temperature zone upstream;

[0025] (4) Under high vacuum conditions, in an inert gas atmosphere, heat the high temperature zone of the CVD furnace to 650°C at a heating rate of 10°C / min at 50Pa, and keep it warm for 15 minutes; after the reaction is completed, the li...

Embodiment 2

[0026] Embodiment 2, the substrate and MoO in the step (3) in embodiment 1 3 Put them into two crucibles respectively, and the crucible where the substrate is located is located downstream and next to MoO 3 Powder place crucible is placed, and the heating rate in step (4) is changed into 15 ℃ / min, all the other are equal to example 1.

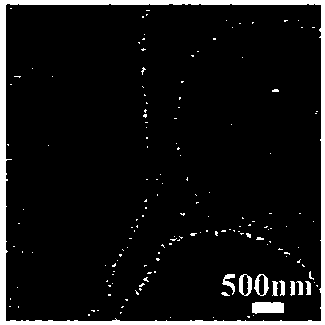

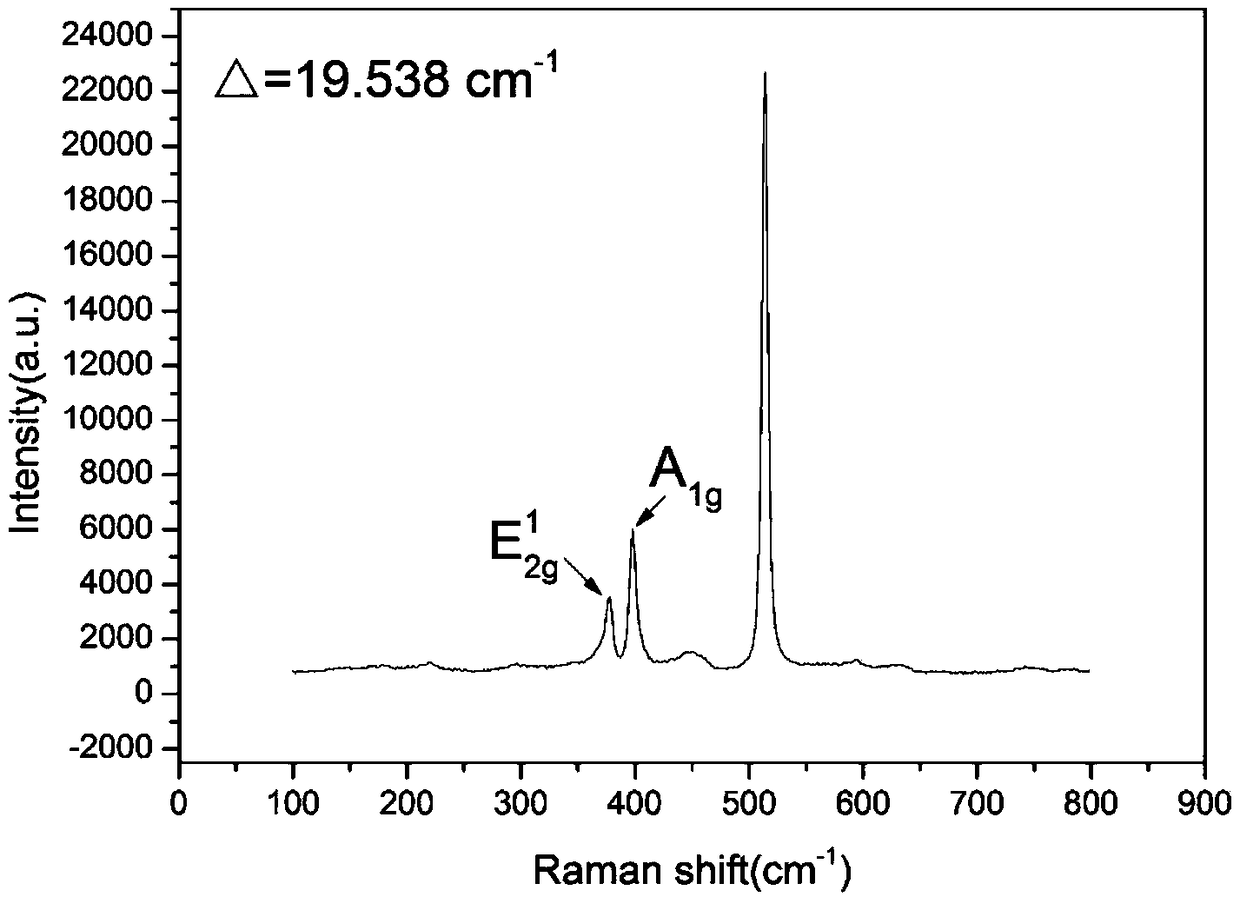

[0027] The AFM of the molybdenum disulfide that embodiment 1 prepares is as figure 1 Shown: It can be seen from the figure that MoS 2 It is in the form of a porous film. In addition, as a supplement, the structure under the pores is scanned by AFM, showing a smooth substrate; combined with the Raman detection map ( figure 2 ), it can be seen that MoS 2 The wavenumber difference △ between the two characteristic peaks is 19.538cm -1 (It is generally believed that the wave number difference △≤20cm -1 is a single layer), so the prepared MoS 2 single-layer porous structure.

[0028] Comparative example 1, the AFM characterization of the moly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com