Preparation method for room temperature NO2 sensor with ceramic-based vanadium oxide nanorod structure

A vanadium oxide and nanorod technology, applied in the direction of material resistance, can solve the problems of cumbersome procedures and high cost of gas sensors, and achieve the effects of less process conditions, convenient use, and quick response to recovery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Cleaning of ceramic substrates

[0034] Cut a piece of ceramic sheet with a size of 2cm*2cm into two rectangular pieces with a size of 2cm*1cm, then put a complete and two cut pieces of ceramic sheet into a glass, and ultrasonically clean them in acetone and ethanol respectively 5-20 minutes, after cleaning, take out the ceramic substrate and blow off the liquid on the surface of the substrate with a suction ball, after absorbing the liquid, put it on the filter paper and dry it in a vacuum oven at 60-80°C for 5-10 minutes for later use;

[0035] (2) Weigh V 2 o 5 powder

[0036] Weighing 0.15gV 2 o 5 powder spare;

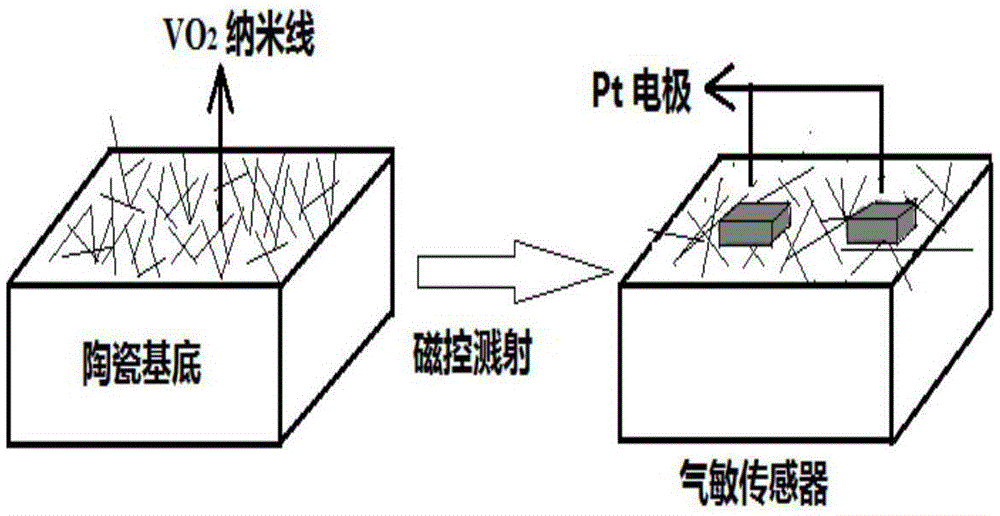

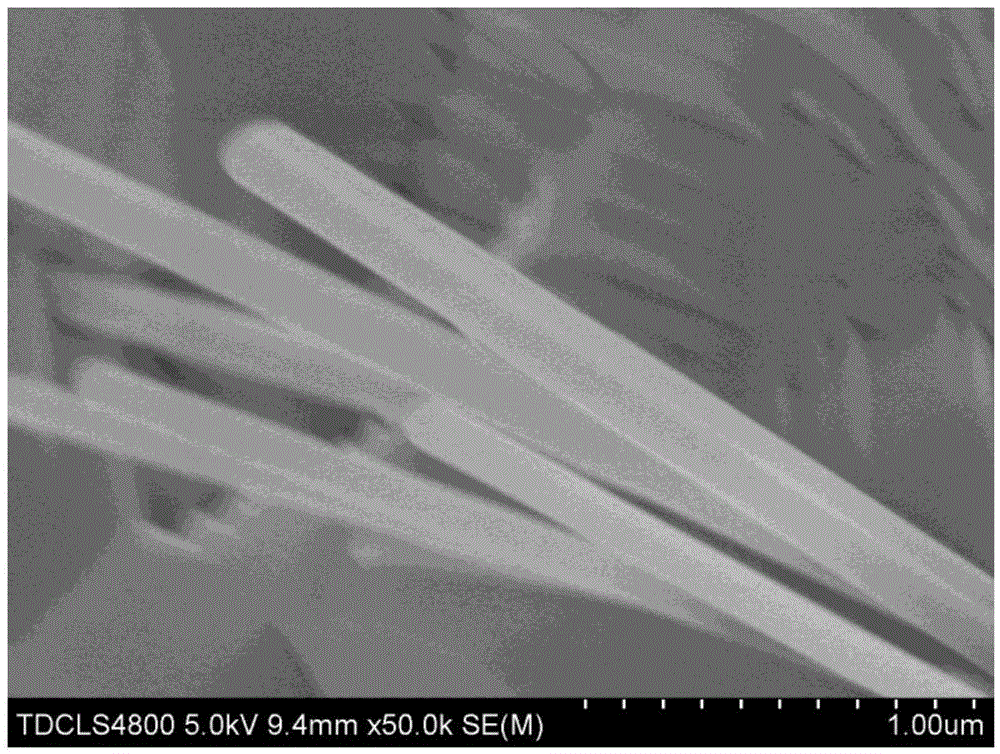

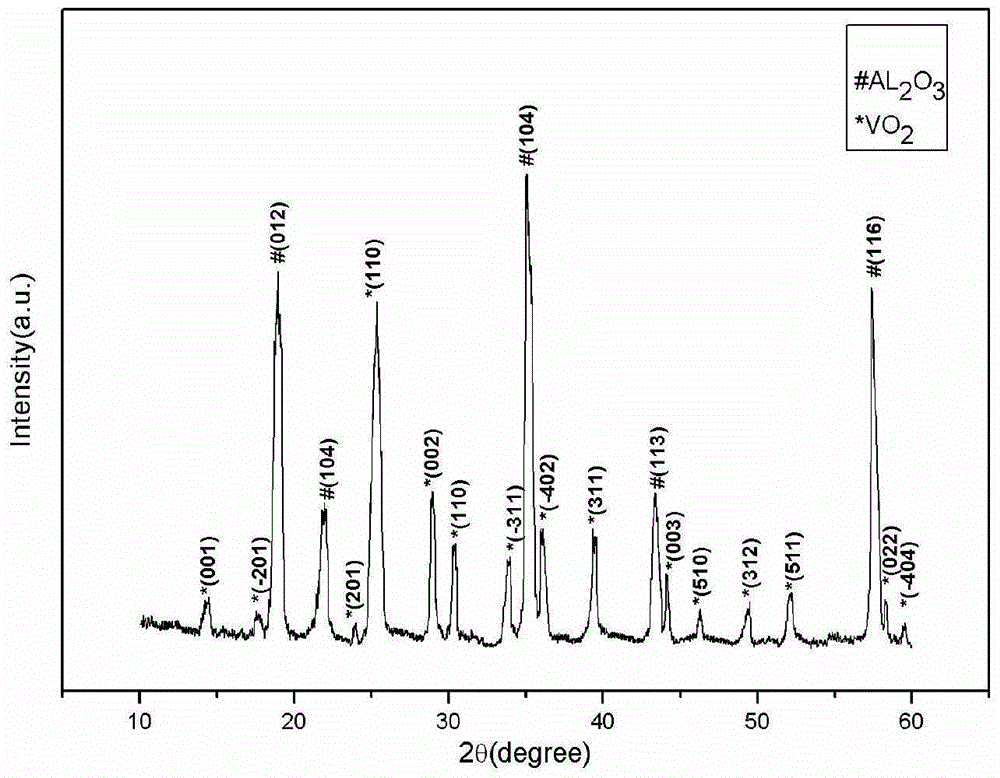

[0037] (3) Preparation of ceramic-based vanadium oxide nanorods by single gas phase transport method

[0038] V of step (2) 2 o 5 Spread the powder evaporation source evenly on the 2cm*2cm ceramic substrate in step (1), and put it into the quartz tube as a whole, and then place it at a distance of V 2 o 5Place two ceramic substrates of 2cm*1cm...

Embodiment 2

[0044] The difference between this example and Example 1 is that: in step (3), the setting working temperature for preparing ceramic-based vanadium oxide nanorods by single vapor transport method is 950°C, and the prepared ceramic-based vanadium oxide nanorods structure gas sensor Sensor element at room temperature to 3ppmNO 2 Gas has a sensitivity of 1.73.

Embodiment 3

[0046] The difference between this example and Example 1 is that: in step (3), the setting working temperature for the preparation of ceramic-based vanadium oxide nanorods by the single gas-phase transport method is 900°C, and the prepared ceramic-based vanadium oxide nanorods structure gas sensor Sensor element at room temperature to 3ppmNO 2 Gas has a sensitivity of 1.62.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com