Ammonium molybdate modified catalyst as well as preparation method and application thereof

A technology of ammonium molybdate and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., and can solve the problems of easy "death, long distance, slow response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the present invention, the preparation method of described ammonium molybdate modified ferrous disulfide comprises the steps:

[0039] (1) Ammonium molybdate, ferrous sulfate heptahydrate, sodium thiosulfate and elemental sulfur are dissolved to obtain a mixed solution;

[0040] (2) Centrifuging the mixed solution after heating to obtain a precipitate;

[0041] (3) washing, centrifuging and drying the precipitate in sequence to obtain the ammonium molybdate-modified ferrous disulfide.

[0042] In the present invention, the mass ratio of ammonium molybdate and ferrous sulfate heptahydrate in the step (1) is preferably 0.15~0.2:7.5~7.6, more preferably 0.16~0.19:7.52~7.58, more preferably 0.17~ 0.18: 7.54 to 7.56.

[0043] In the present invention, the mass ratio of the ammonium molybdate to sodium thiosulfate is preferably 0.15-0.2: 7.5-7.6, more preferably 0.16-0.19: 7.52-7.58, more preferably 0.17-0.18: 7.54-7.56.

[0044] In the present invention, the mass ratio...

Embodiment 1

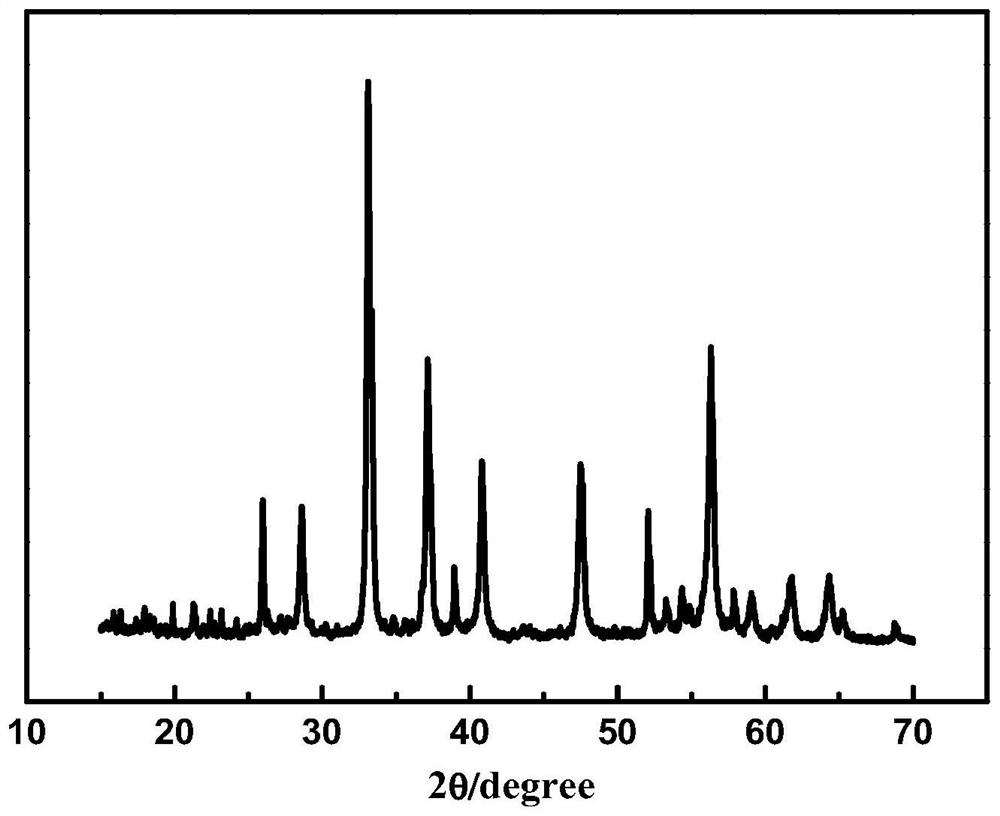

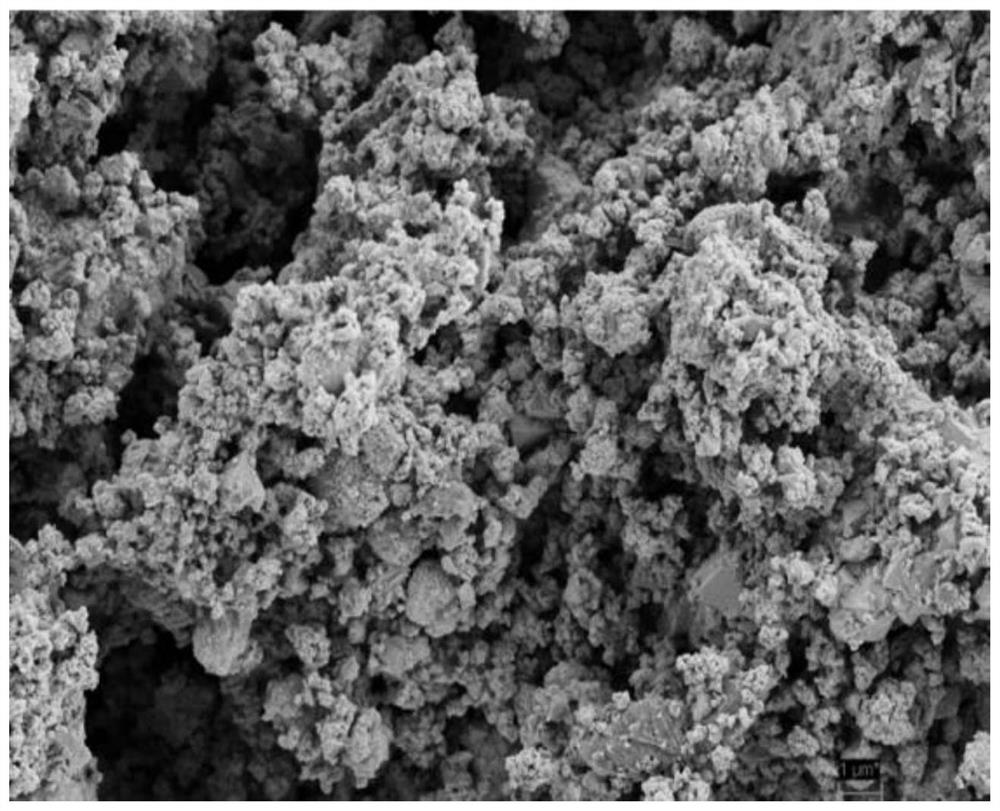

[0072] Preparation of ammonium molybdate modified ferrous disulfide:

[0073] Weigh 0.1700g ammonium molybdate, 7.5955g ferrous sulfate heptahydrate, 7.9054g sodium thiosulfate and 0.8016g elemental sulfur respectively, place the three materials in a ball mill and mill them for 40min at a speed of 400rpm. Mixed with ionic water; ultrasonically stirred at 50kHz, 1300rpm for 30min to dissolve to obtain a mixed solution;

[0074] The mixed solution was heated at 180°C for 24 hours to react, and after heating, it was cooled to room temperature, the reaction system was placed in a centrifuge tube, and centrifuged at 1100 rpm for 8 minutes to obtain a precipitate;

[0075] Wash the precipitate with distilled water 5 times, the amount of distilled water used for each cleaning is 40mL, centrifuge at 1100rpm for 8min after each cleaning, and centrifuge five times in total; after cleaning with distilled water, use carbon tetrachloride to wash 5 times, each time The consumption of clean...

Embodiment 2

[0095] Preparation of ammonium molybdate modified ferrous disulfide:

[0096] Weigh 0.1812g ammonium molybdate, 7.5623g ferrous sulfate heptahydrate, 7.5418g sodium thiosulfate and 0.8283g elemental sulfur respectively, put the three kinds of materials in a ball mill and mill them for 50min at a speed of 450rpm. Mixed with ionic water; ultrasonically stirred at 56kHz, 1360rpm for 25min to dissolve to obtain a mixed solution;

[0097] The mixed solution was heated at 185°C for 23h to react, and after heating, it was cooled to room temperature, the reaction system was placed in a centrifuge tube, and centrifuged at 1160rpm for 6min to obtain a precipitate;

[0098] The precipitate was washed 6 times with distilled water, and the amount of distilled water used for each cleaning was 30mL. After each cleaning, it was centrifuged at 1160rpm for 6 minutes, and it was centrifuged six times in total; The amount of carbon tetrachloride used for cleaning is 30mL, centrifuged at 1160rpm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com