A kind of preparation method of low temperature bainitic steel

A bainitic steel and bainite technology, which is applied in the field of low temperature bainitic steel preparation, can solve problems such as long manufacturing time, and achieve the effects of easy operation, increased nucleation rate, and increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The embodiment of the present invention provides a method for preparing nano-bainite steel. The chemical composition and content of the steel are: C: 0.81wt%, Si: 1.67wt%, Mn: 2.01wt%, Cr: 1.00wt% , Mo: 0.26wt%, Co: 3.70wt%, Al: 1.30wt%, and the rest are Fe and unavoidable impurities.

[0044] Its preparation method specifically comprises the following steps:

[0045]S1. Spheroidize and anneal the test steel at 820°C for 2h in a box furnace to improve its cutting performance, and then homogenize it at 1100°C for 48h under vacuum conditions (60Pa) to reduce the impact of alloy element segregation on the structure The impact, finally, was machined into a 4 x 4 x 4mm square specimen by wire cutting.

[0046] Under the premise of ensuring that the surface to be observed is parallel to the lower surface, the surface to be observed of the sample is ground and polished until there is no scratch on the surface; with Gleeble3500 thermal simulation testing machine, the martensit...

Embodiment 2

[0051] The embodiment of the present invention provides a method for preparing nano-bainite steel. The chemical composition and content of the steel are: C: 0.81wt%, Si: 1.67wt%, Mn: 2.01wt%, Cr: 1.00wt% , Mo: 0.26wt%, Co: 3.70wt%, Al: 1.30wt%, and the rest are Fe and unavoidable impurities.

[0052] Its preparation method specifically comprises the following steps:

[0053] S1. Spheroidize and anneal the test steel at 820°C for 2h in a box furnace to improve its cutting performance, and then homogenize it at 1100°C for 48h under vacuum conditions (60Pa) to reduce the impact of alloy element segregation on the structure The impact, finally, was machined into a 4 x 4 x 4mm square specimen by wire cutting.

[0054] Similar to Example 1, under the premise of ensuring that the surface to be observed is parallel to the lower surface, the surface to be observed of the sample is ground and polished until there is no scratch on the surface; the martensitic phase of the sample is meas...

Embodiment 3

[0059] The embodiment of the present invention provides a method for preparing nano-bainite steel. The chemical composition and content of the steel are: C: 0.81wt%, Si: 1.67wt%, Mn: 2.01wt%, Cr: 1.00wt% , Mo: 0.26wt%, Co: 3.70wt%, Al: 1.30wt%, and the rest are Fe and unavoidable impurities.

[0060] The preparation method is similar to that of Example 1, except that in step S2, austenitize at 1000°C for 30 minutes, then cool to 168°C at a rate of 4°C / s, hold for 30s, and then heat up to 188°C within 3s , keep warm for 30s, and finally keep warm for 40min at 300°C, which is the QBT process.

[0061] The physical and mechanical properties of the nano-bainitic steel prepared in this embodiment are: yield strength R eL is 1572.5MPa, the tensile strength R m It is 1948.8MPa, the impact energy is 12.6J, and the elongation is 12.56%. It has both high strength and excellent plasticity and toughness.

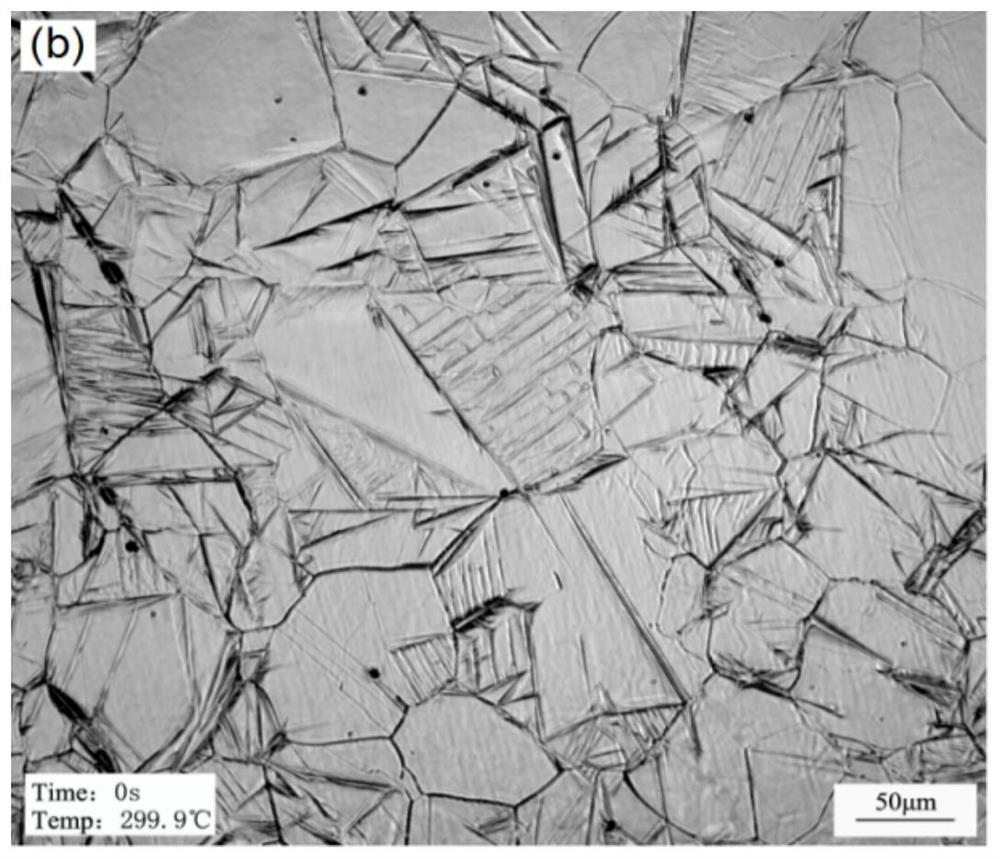

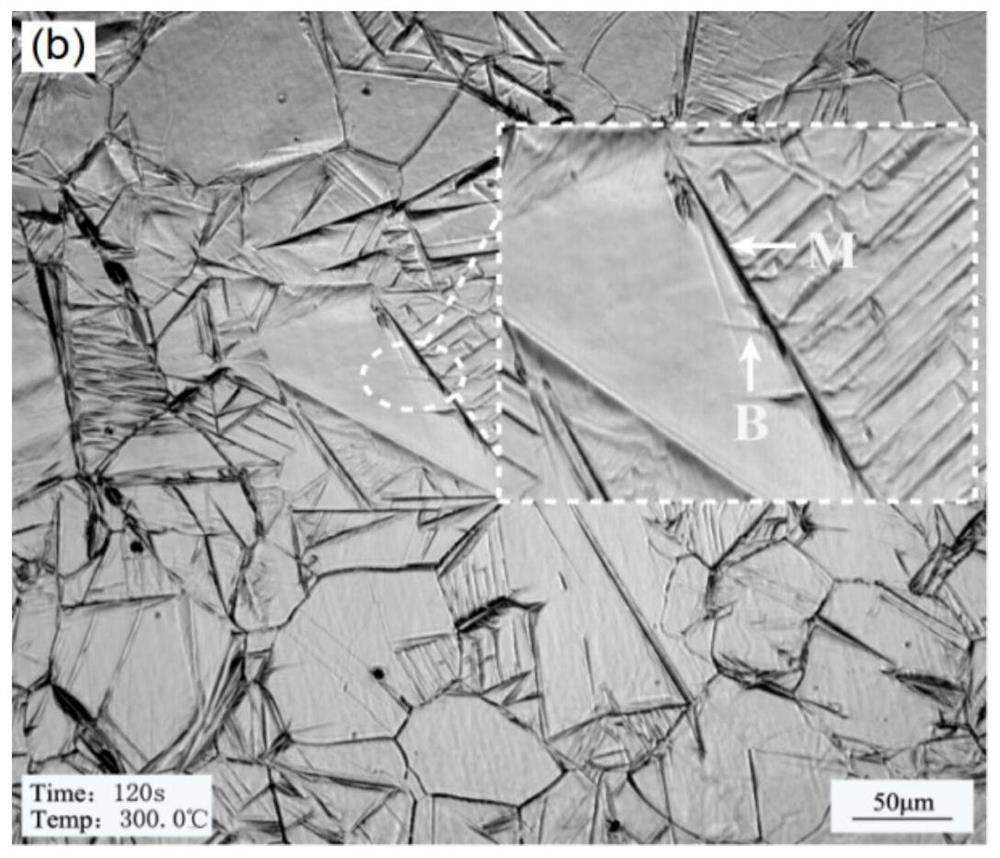

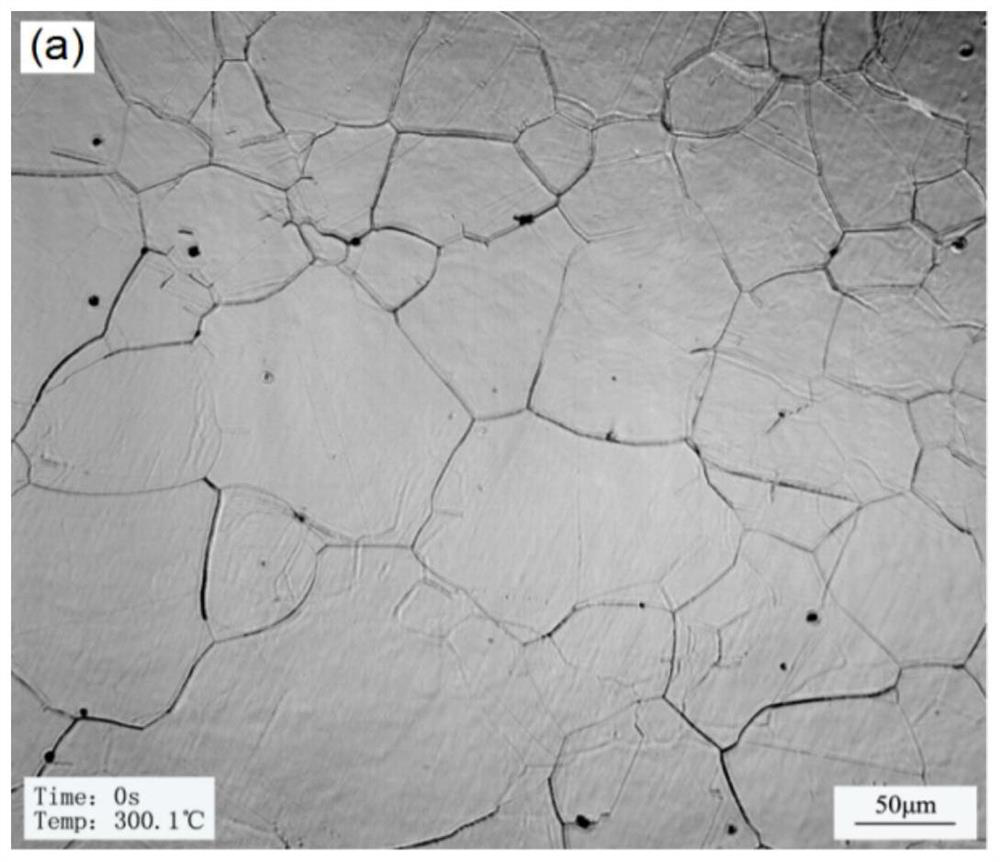

[0062] Comparative analysis figure 2 and Figure 4 From the results, it can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com