Sliding disc type axial plunger pump

A technology of axial piston pump and sliding plate type, which is applied in the direction of variable displacement pump components, pumps, pump elements, etc., to achieve the effects of simplified structure, small inertia and reduced lateral force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

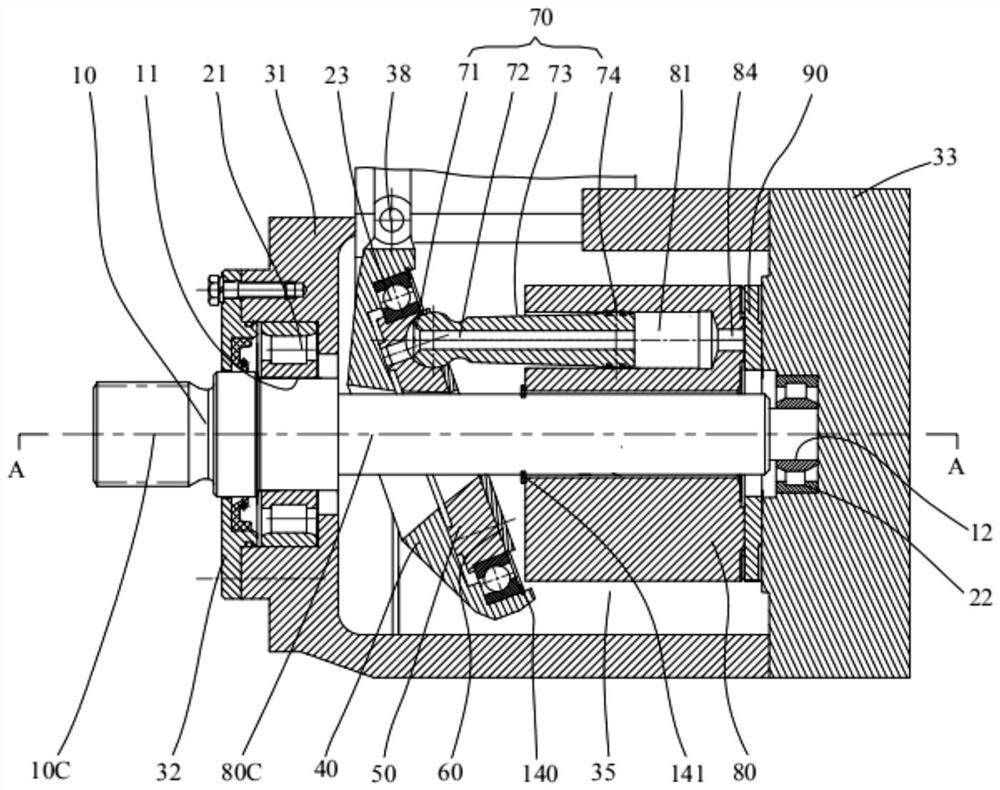

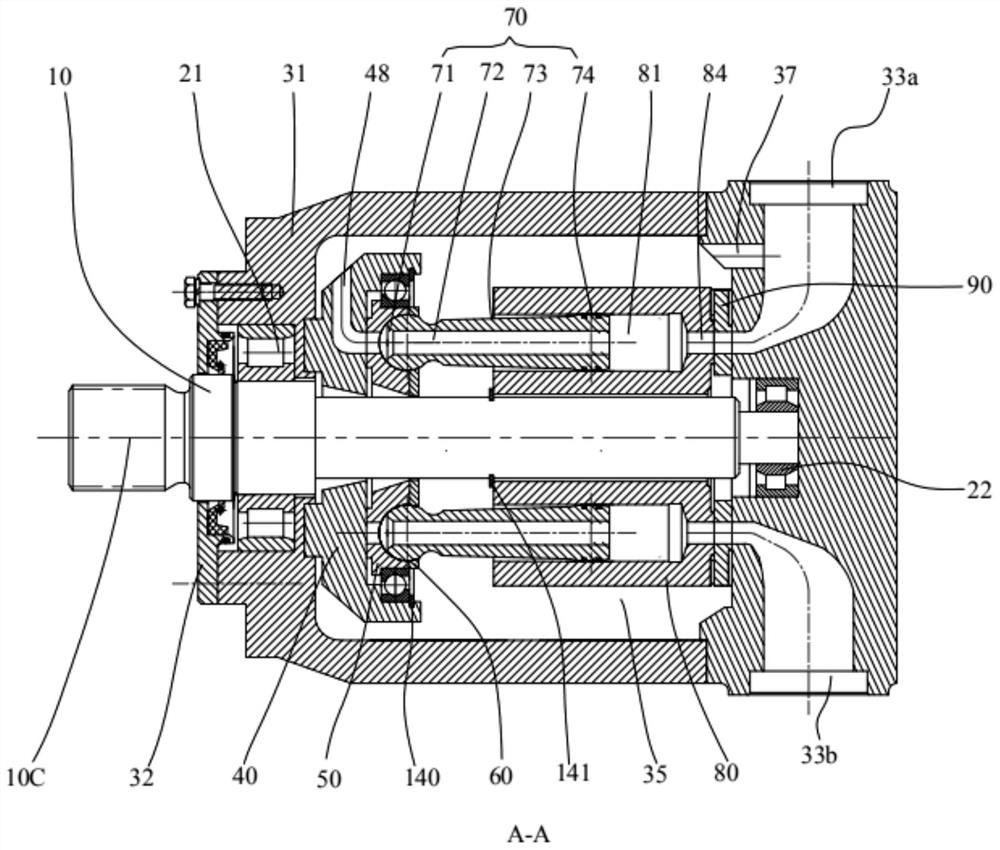

[0053] like Figures 1 to 11 As shown, it is a preferred embodiment of the axial piston pump of the present invention. In the preferred embodiment shown, the piston pump is a through-shaft type piston pump, including a main shaft 10, a housing 31, a first bearing 21. The second bearing 22, the distribution sliding plate pair, the plunger pair, the distribution pair and the rear end cover 33, the rear end cover 33 is provided with a communication groove 37 that communicates with the housing cavity 35, the main shaft of the main shaft 10 The axis 10C coincides with the cylinder axis 80C of the cylinder block 80 . One end of the main shaft 10 penetrates the distribution sliding plate pair and extends out of the housing 31 and is supported on the first bearing 21 , and the other end penetrates the distribution pair and is supported on the second bearing. 22, the cylinder body 80 is supported on the main shaft 10 and is connected with the main shaft through a key to realize synchro...

Embodiment 2

[0080] like Figure 13 As shown, another embodiment of the present invention is shown. The difference from Embodiment 1 is that an impeller 150 is provided on the outer periphery of the cylinder block 80 .

[0081] The impeller 150 is fixed on the cylinder block 80 and rotates synchronously with the cylinder block. Under the action of the impeller, the oil inside the casing forms a certain oil pressure and moves in a directional motion, that is, the oil is driven toward the oil inlet groove 48 of the swash plate 40 . The advantages of this structure are as follows: First, the flow of hot oil in the cavity 35 of the casing is accelerated, so that it leaves the vicinity of the friction pair as soon as possible to reduce the influence of high temperature on the friction pair; second, the oil suction flow on the sliding plate side is increased, and the oil absorption performance is enhanced. .

Embodiment 3

[0083] like Figures 14 to 18 As shown, another embodiment of the present invention is shown, and the difference from Embodiment 1 lies in the difference between the position of the valve plate sliding plate pair and the valve pair, and the difference in the distribution channel caused by the difference , and other structures can be referred to in Example 1.

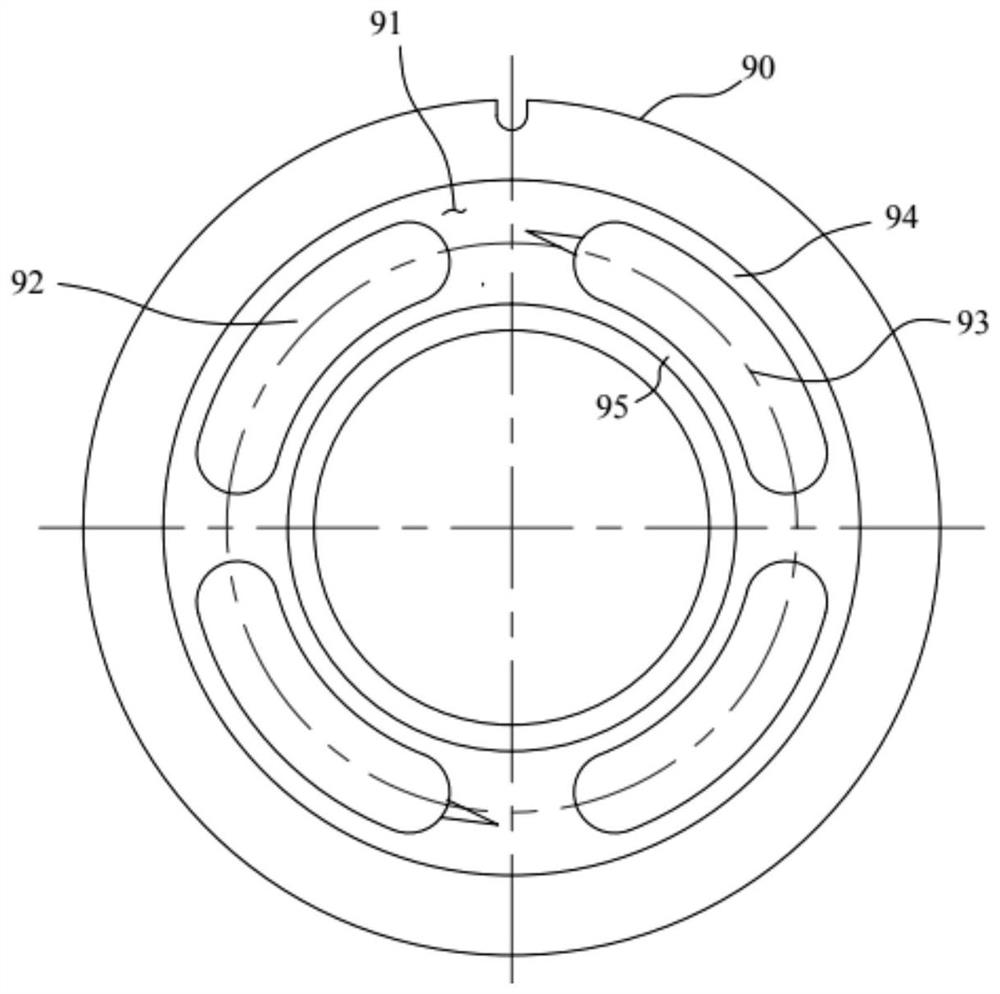

[0084] The distribution pair includes a cylinder block 80 and a distribution plate 90 abutting on the casing 31 . The cylinder block 80 and the distribution plate 90 are supported in a hydrostatic manner and transmit the axial force to the casing. The distribution pair is a single valve. To the low pressure distribution pair, the distribution pair includes the end of the cylinder body and the distribution plate 90 supported on the housing 31 , the end of the cylinder body and the end surface of the distribution plate 90 form a gap-fitted hydrostatic oil film support and the two keep sliding In cooperation, a low pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com