Superposition method for welding ceramic and aluminum

A technology of welding method and superposition method, which is applied in the field of material processing, can solve problems such as difficulties, reduce the strength of welding joints, cracking, etc., and achieve the effects of convenient processing, avoiding ceramic cracking, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

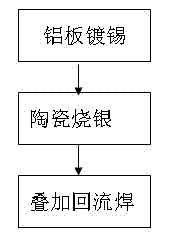

Method used

Image

Examples

Embodiment Construction

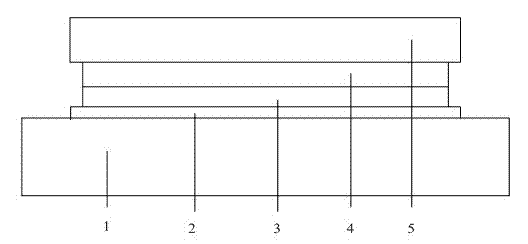

[0015] At present, there are generally two types of welding between ceramics and metals: brazing and diffusion welding. Brazing must be metallized on the ceramic surface, and then brazed with brazing filler metal. However, the method for pre-metallizing ceramics is complicated in technology, and its application is subject to many restrictions. Diffusion welding requires that under a certain temperature and pressure, the connected surfaces are close to each other and in contact with each other, and the physical contact of the connected surfaces is expanded by causing a transient liquid phase locally to form a stable reaction gradient layer to combine the two materials. Together. This method requires higher pressure and temperature, which cannot be produced by ordinary processes. We adopt the ordinary ceramic thick film sintering method, which does not require high pressure or ceramic pre-metallization, and the process is simple and feasible. Thick film refers to a film layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com