Halogen-free active fire retardant and preparation method thereof

A flame retardant and active technology, applied in the field of halogen-free active flame retardants and their preparation, can solve problems such as environmental pollution, achieve the effects of good compatibility, high yield and easy commercial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

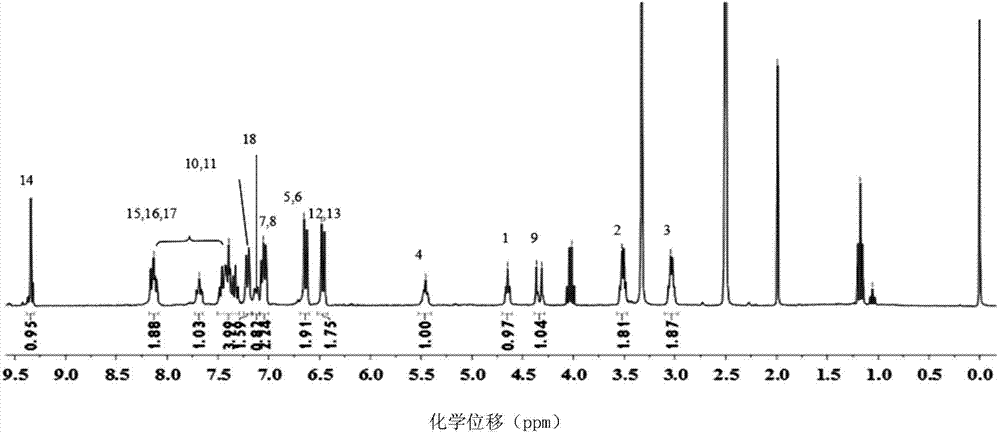

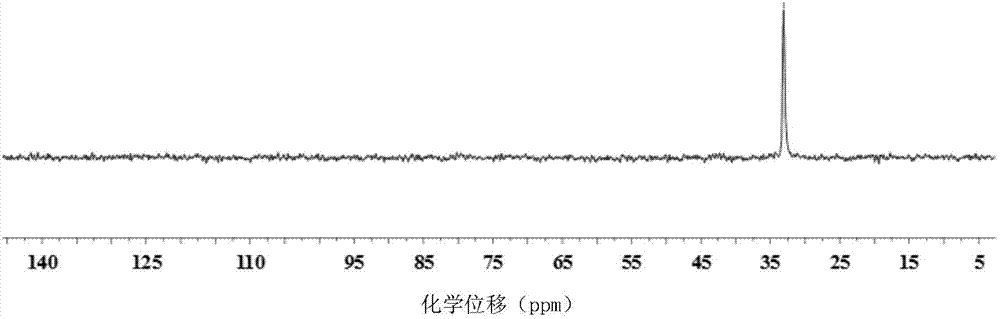

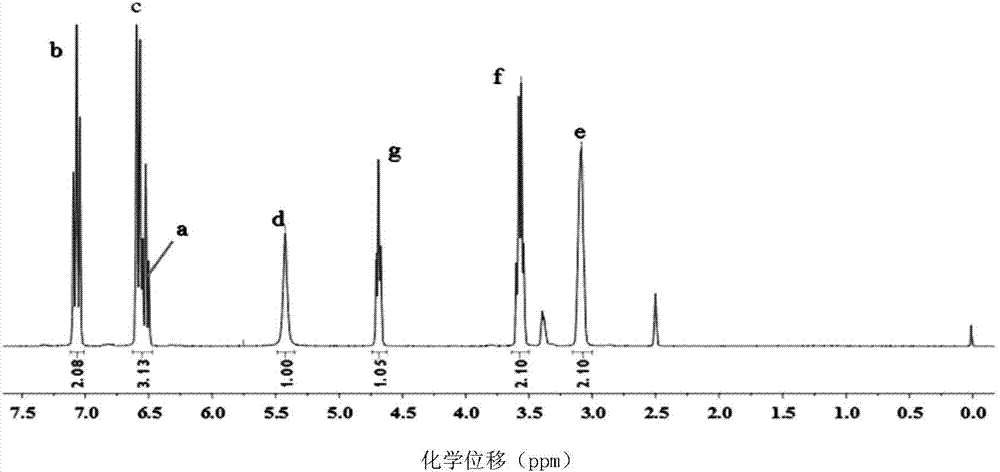

[0025] Under nitrogen protection, add reactant N-hydroxyethylaniline (13.718g, 0.1mol), 4-hydroxybenzaldehyde (12.212g, 0.1mol) and 200ml of toluene, heat up to 90°C, keep the system under reflux for 2 hours, then add DOPO (21.6g, 0.1mol) and continue the reaction for 4 hours, a light blue solid precipitate can be obtained, cool down, let stand, pour off the upper solvent, and then use The solvent was washed 3 times, put into a vacuum oven at elevated temperature (60°C) and dried to obtain 42.32 g of light blue solid product DOPO-PEA, with a yield of 89.03%.

Embodiment 2

[0027] Under nitrogen protection, add reactant N-hydroxyethylaniline (7.544g, 0.055mol), 4-hydroxybenzaldehyde (6.106g, 0.05mol) and 100ml of toluene, heat up to 90°C, keep the system under reflux for 2 hours, then add DOPO (10.8g, 0.05mol) and continue the reaction for 3 hours, a light blue solid precipitate can be obtained, cool down, let stand, pour off the upper solvent, and then use The solvent was washed 3 times, put into a vacuum oven and dried at elevated temperature (50° C.) to obtain 22.02 g of light blue solid product DOPO-PEA, with a yield of 90.06%.

Embodiment 3

[0029] Under nitrogen protection, add reactant N-hydroxyethylaniline (16.462g, 0.12mol), 4-hydroxybenzaldehyde (12.212g, 0.1mol) and 200ml of toluene, heat up to 80°C, keep the system under reflux for 4 hours, then add DOPO (21.6g, 0.1mol) and continue the reaction for 4 hours, a light blue solid precipitate can be obtained, cool, let stand, pour off the upper solvent, and then use The solvent was washed 3 times, put into a vacuum oven and dried at elevated temperature (60° C.) to obtain 43.82 g of light blue solid product DOPO-PEA, with a yield of 87.17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com