High-strength ageing-resistant cable

An anti-aging, high-strength technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of varieties and performances that cannot meet domestic demand, shorten the service life of cables, and lose functions of cables, so as to shorten the vulcanization time and increase the thickness of the sheet The effect of increasing the distance and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

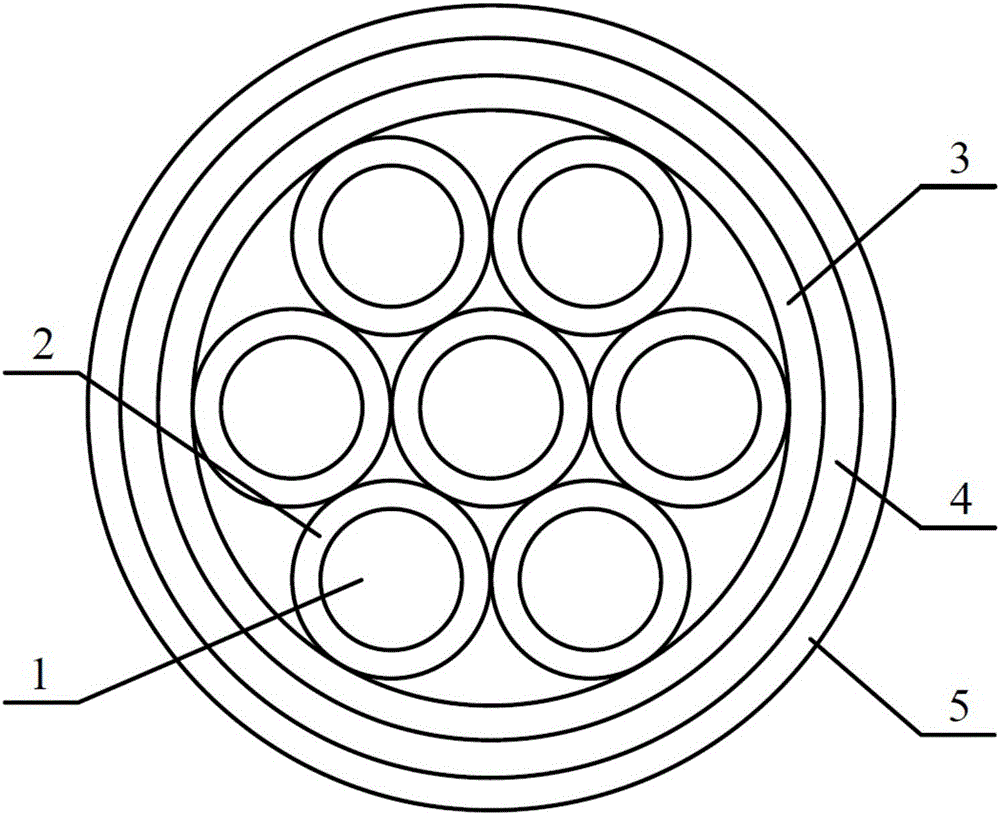

[0022] figure 1 It is a schematic structural view of the high-strength aging-resistant cable of the present invention, with reference to figure 1 The high-strength aging-resistant cable of the present invention includes a cable core, and the cable core includes a conductor 1 located in the middle and an insulating layer 2 coated on the outside of the conductor; an inner sheath layer 3 is provided outside the cable core, and the inner sheath A steel tape armor layer 4 is arranged outside the layer 3, an outer sheath layer 5 is arranged outside the steel tape armor layer 4, and the outer sheath layer 5 is made of a modified natural rubber material, wherein the raw material of the modified natural rubber material Include the following components by weight: 80 parts of natural rubber, 15 parts of epoxy resin, 5 parts of fluorine micropowder, 25 parts of white carbon black, 3 parts of nylon short fiber, 20 parts of modified calcium carbonate whiskers, 10 parts of modified nano tita...

Embodiment 2

[0025] refer to figure 1 The high-strength aging-resistant cable of the present invention includes a cable core, and the cable core includes a conductor 1 located in the middle and an insulating layer 2 coated on the outside of the conductor; an inner sheath layer 3 is provided outside the cable core, and the inner sheath A steel tape armor layer 4 is arranged outside the layer 3, an outer sheath layer 5 is arranged outside the steel tape armor layer 4, and the outer sheath layer 5 is made of a modified natural rubber material, wherein the raw material of the modified natural rubber material Include the following components by weight: 95 parts of natural rubber, 3 parts of epoxy resin, 2 parts of fluorine micropowder, 5 parts of white carbon black, 12 parts of nylon short fiber, 5 parts of modified calcium carbonate whiskers, 25 parts of modified nano titanium dioxide 1 part, 1 part of nano-alumina, 4 parts of stearic acid, 1.5 parts of zinc oxide, 3.5 parts of sulfur, 0.3 par...

Embodiment 3

[0029] refer to figure 1 The high-strength aging-resistant cable of the present invention includes a cable core, and the cable core includes a conductor 1 located in the middle and an insulating layer 2 coated on the outside of the conductor; an inner sheath layer 3 is provided outside the cable core, and the inner sheath A steel tape armor layer 4 is arranged outside the layer 3, an outer sheath layer 5 is arranged outside the steel tape armor layer 4, and the outer sheath layer 5 is made of a modified natural rubber material, wherein the raw material of the modified natural rubber material Include the following components by weight: 86 parts of natural rubber, 10 parts of epoxy resin, 4 parts of fluorine micropowder, 20 parts of white carbon black, 7 parts of nylon short fiber, 18 parts of modified calcium carbonate whiskers, 16 parts of modified nano titanium dioxide 4.2 parts, 4.2 parts of nano-alumina, 2.8 parts of stearic acid, 2.6 parts of zinc oxide, 3.2 parts of sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com