Anti-cracking silicone rubber cable material and preparation method thereof

A technology of silicone rubber and cable materials, applied in rubber insulators, organic insulators, etc., can solve problems such as easy cracking of cable materials, and achieve the effect of improving crack resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

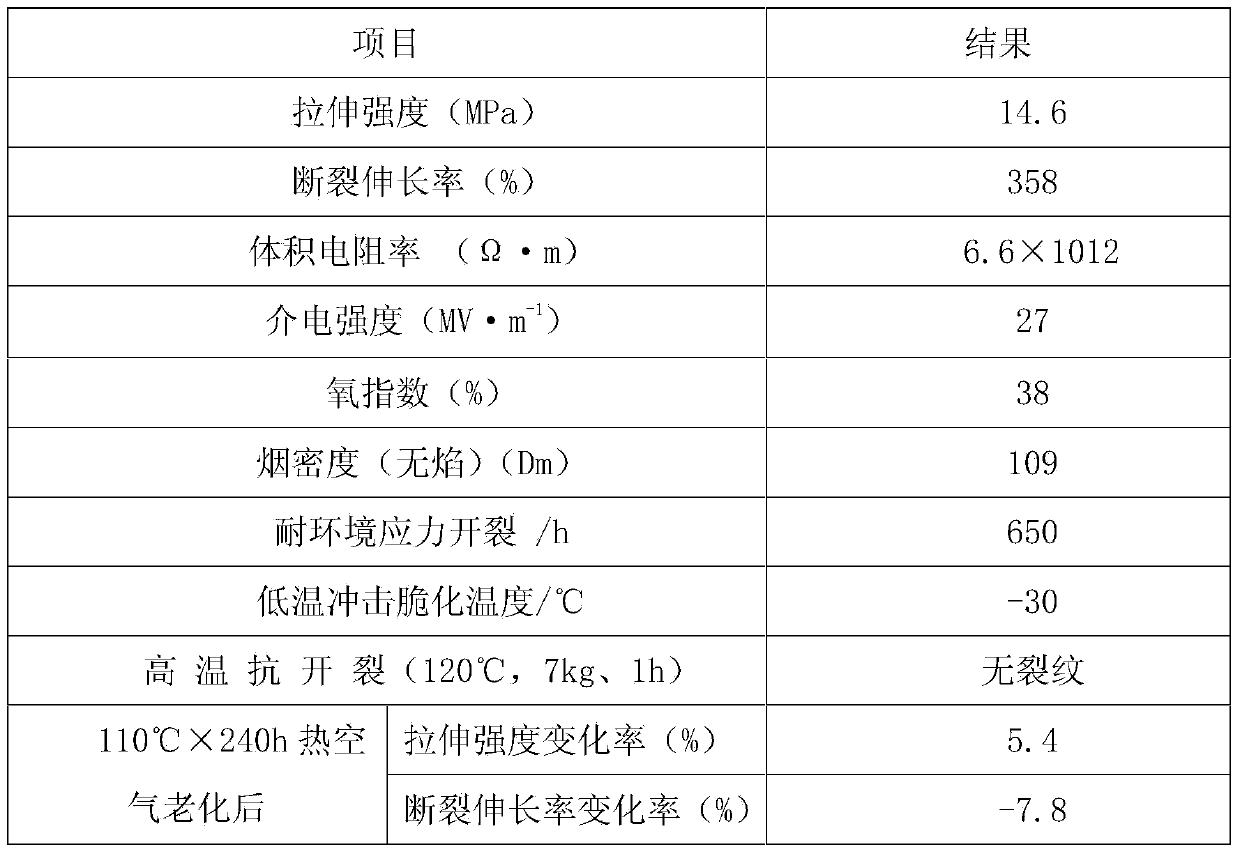

Examples

Embodiment Construction

[0012] An anti-cracking silicone rubber cable material, made of the following raw materials by weight (kg): methyl vinyl silicone rubber 70, nylon 6628, isotactic polypropylene 12, magnesium hydroxide 16, sodium molybdate 8, melamine cyanurate Salt 10, magnesium oxide 2, diisononyl phthalate 10, methyl tin mercaptide 2, polyethylene wax 7, antioxidant BHT1, vulcanizing agent DTBP1, accelerator TETD1.5, anti-scorch agent CTP0.8 , carbon black N66018, vermiculite powder 16, nano-alumina 8, composite filler 5;

[0013] The preparation method of the composite filler is as follows: a. Take the raw materials of the following weight (kg): kaolin 10, celestite 10, corundum powder 4, nano-aluminum nitride 6, N-2-(aminoethyl)-3-ammonia Propyltrimethoxysilane 2, triallyl cyanurate 1.5, nano-aluminum hydroxide 10, zinc stearate 2.5, antioxidant ODA 1.5; b, calcining kaolin and lapis lazuli at 520°C for 4 hours , after cooling to room temperature, add an appropriate amount of water togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com