The preparation method of tetraethylthiuram disulfide

A technology of tetraethylthiuram disulfide and carbon disulfide, applied in the field of rubber additives, can solve the problems of environmental pollution, complicated process, low yield and the like, and achieve the effects of reducing production cost, simple and convenient process operation, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

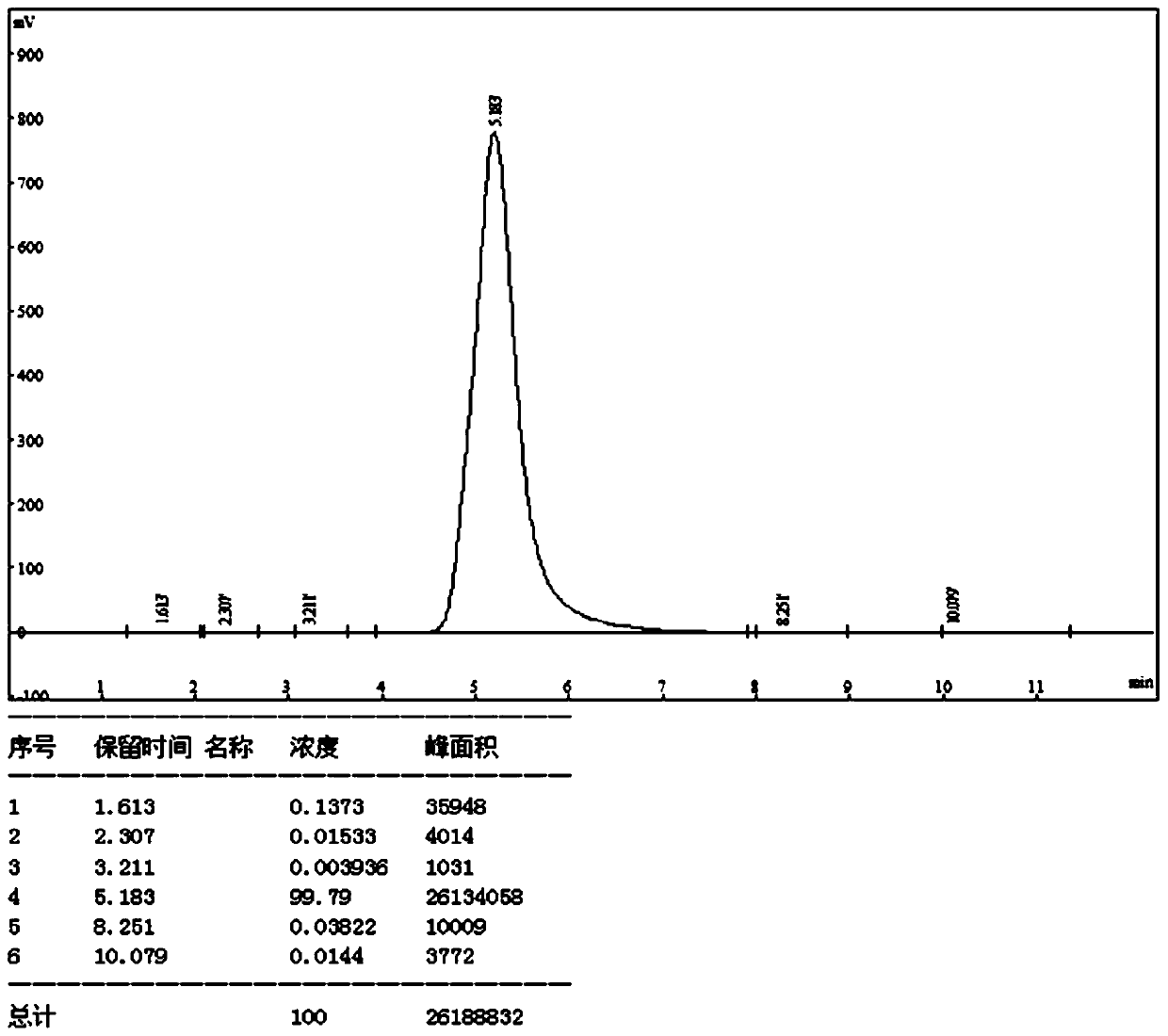

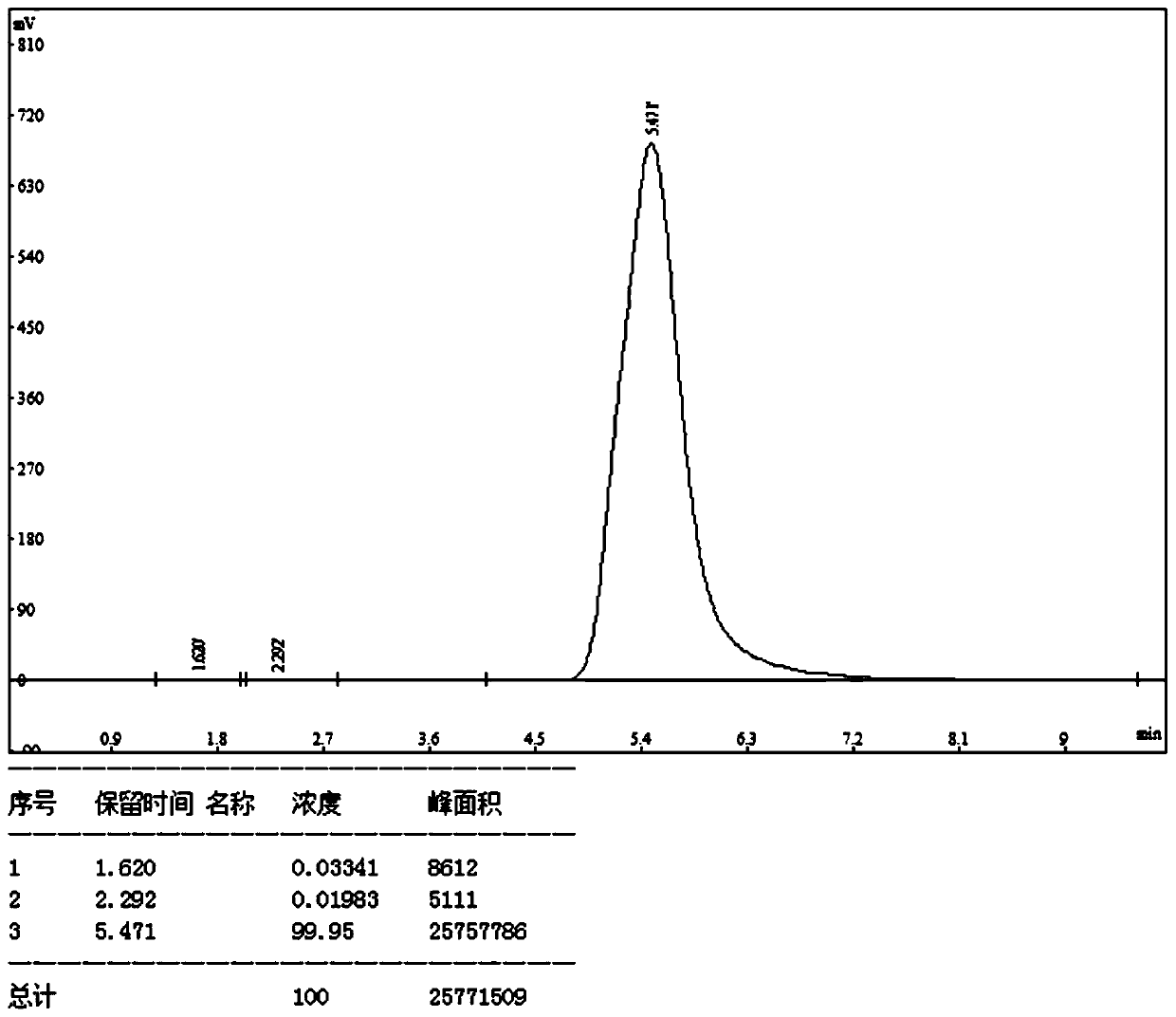

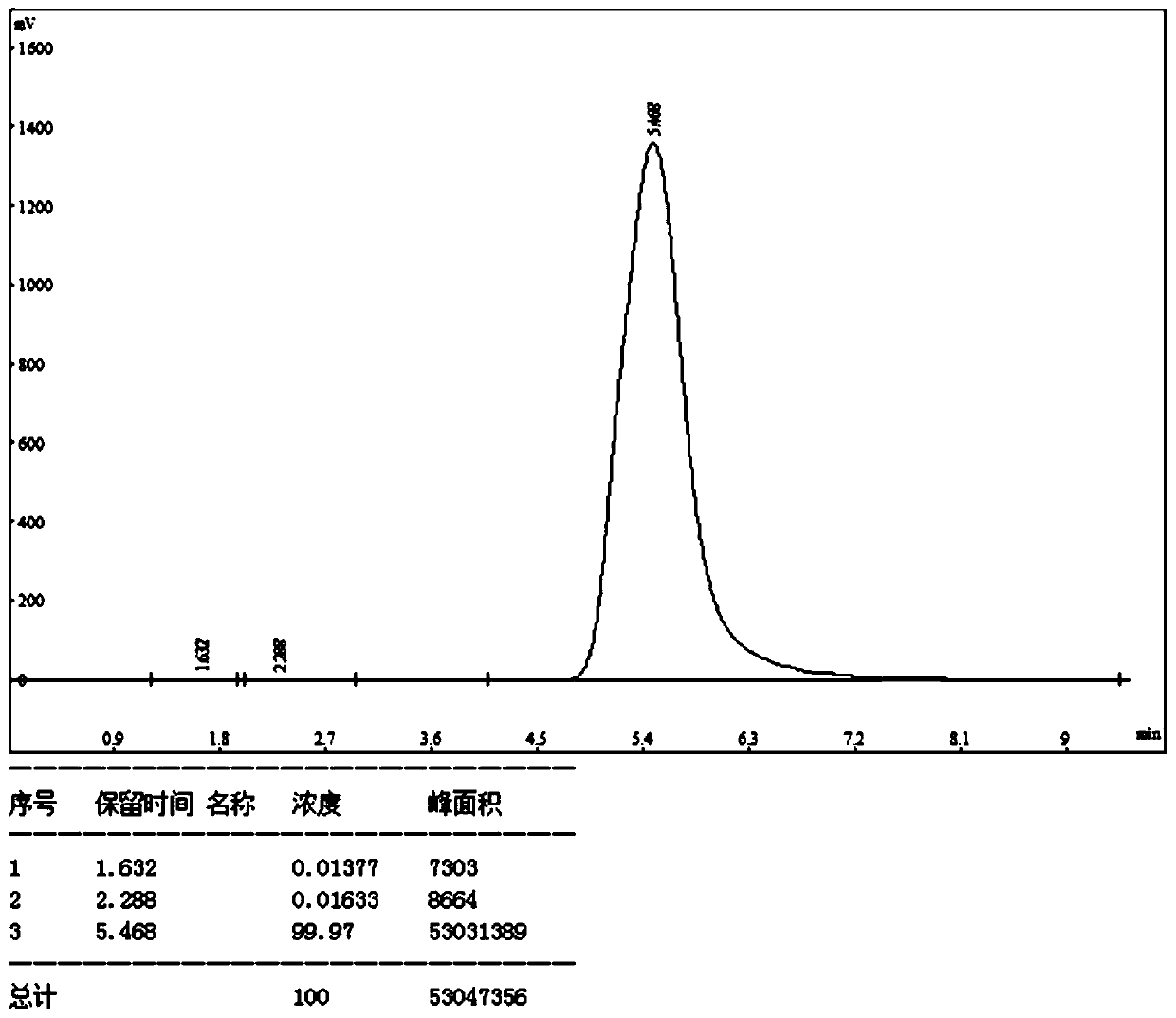

Image

Examples

preparation example Construction

[0049] In one embodiment of the present invention, the preparation method comprises the following steps:

[0050] Step a): Adding carbon disulfide to a solution containing a bimetallic catalyst and diethylamine by means of dropwise addition to react carbon disulfide and diethylamine to obtain a first solution;

[0051] Step b): adding hydrogen peroxide dropwise to the obtained first solution for reaction, and obtaining the tetraethylthiuram disulfide after the reaction is completed.

[0052] The separate operation of the dropwise addition of carbon disulfide and hydrogen peroxide can promote the reaction to proceed more fully, better control the temperature during the operation, further improve the reaction efficiency, and increase the product conversion rate.

[0053] In one embodiment of the present invention, in step a), the reaction temperature is 15-25°C, the carbon disulfide addition time is 1.0-1.5h, and the reaction is continued for 0.5-1.0h after the addition;

[005...

Embodiment 1

[0072] The present embodiment is a kind of preparation method of tetraethylthiuram disulfide, comprising the following steps:

[0073] Under normal pressure conditions, 270g n-butanol and 0.09g Pd-Mn-Al 2 o 3 Add it into a 1000ml four-necked bottle for stirring and mixing, then add 60g of diethylamine, control the temperature at 12°C, and start to add 60g of carbon disulfide dropwise. During the dropping process, the temperature is controlled at 12°C, and the dropping time is 40min; React at 12°C for 20 minutes; raise the temperature to 22°C, start adding 48g of hydrogen peroxide dropwise, control the dropping rate so that the reaction temperature is 22°C, and the dropping time is 1.5h; then keep warm for 20 minutes; after the keep warm, start filtering, washing and drying Dried and packaged.

Embodiment 2

[0075] The present embodiment is a kind of preparation method of tetraethylthiuram disulfide, comprising the following steps:

[0076] Under normal pressure conditions, 480g n-butanol and 0.36g Pd-Mn-Al 2 o 3 Add it into a 1000ml four-necked bottle for stirring and mixing, then add 60g of diethylamine, control the temperature at 28°C, and start to add 78g of carbon disulfide dropwise. During the dropping process, the temperature is controlled at 28°C, and the dropping time is 40min; React at 28°C for 20 minutes; raise the temperature to 35°C, start adding 75g of hydrogen peroxide dropwise, control the dropping speed so that the reaction temperature is 35°C, and the dropping time is 1.5h; then keep warm for 20 minutes; after the keep warm, start filtering, washing and drying Dried and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com