A kind of sulfurized hydrogenation catalyst and its preparation method and application

A hydrogenation catalyst and vulcanization-type technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve problems such as poor controllability, complicated preparation process, and high cost question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of vulcanization type hydrogenation catalyst, and this method comprises the following steps:

[0026] (1) Mix the dispersant with solution A containing metal salts of Group VIB, metal salts of Group VIII and sulfur source, the solution A is acidic, and the dispersant is a water-soluble organic solvent with a boiling point of 15-90°C , the sulfur source is a sulfur-containing substance that can be hydrolyzed under acidic conditions at 50-100°C;

[0027] (2) contacting the mixture obtained in step (1) with the catalyst carrier at 60-150° C. for 5-30 hours under airtight conditions;

[0028] (3) Calcining the solid material obtained after contacting in step (2) in an inert or reducing atmosphere.

[0029] In the present invention, preferably, the Group VIII metal is cobalt and / or nickel, and the Group VIB metal is molybdenum and / or tungsten.

[0030] In the present invention, preferably, the Group VIB metal salt...

Embodiment 1

[0089] Prepare an aqueous solution containing 0.15mol / L sodium molybdate, 0.06mol / L nickel nitrate, and 0.45mol / L thioacetamide. During stirring, add 2.4mol / L hydrochloric acid 4.0mL dropwise to obtain 40mL solution A. The pH value is 5.0;

[0090] Measure 20mL of absolute ethanol, and add the absolute ethanol dropwise to solution A at a rate of 1mL / min while stirring continuously to form solution B;

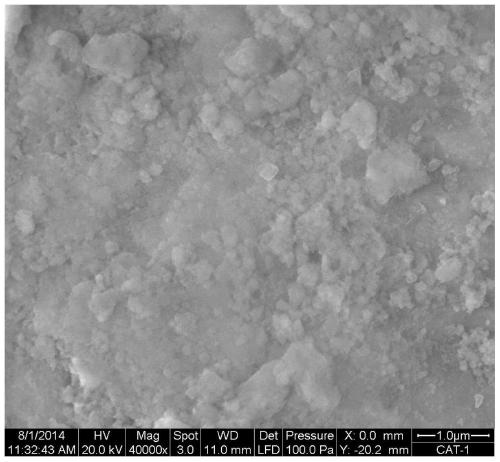

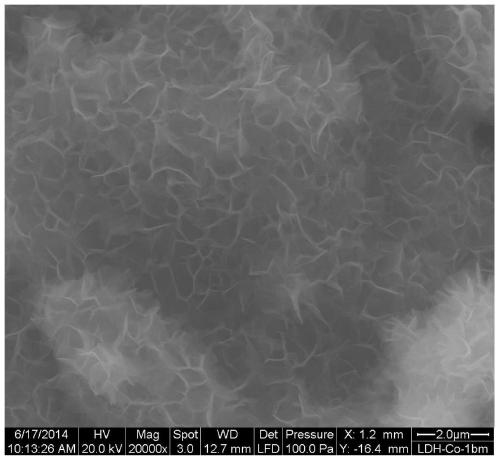

[0091] 4.0g of γ-Al with a diameter of 2-5mm 2 o 3 Particles (surface SEM image see figure 1) immersed in 20.0mL of a mixed aqueous solution containing 0.2mol / L cobalt nitrate and 1.0mol / L urea, heat-treated at 80°C for 24 hours, filtered, washed and then dried at 120°C for 4 hours. ℃ calcination for 4 hours to obtain Co-modified alumina support Z-1, the SEM image of Z-1 is as follows figure 2 shown. From figure 2 It can be seen that the surface of the Co-modified alumina support has a large number of network structures, and the network density is listed in Table 2;

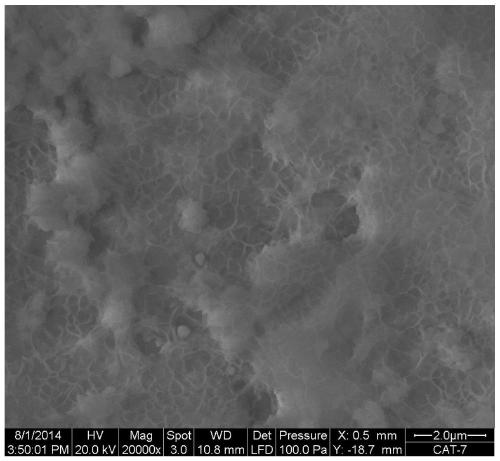

[0...

Embodiment 2

[0094] Prepare an aqueous solution containing 0.20 mol / L sodium tungstate, 0.1 mol / L nickel acetate, and 0.60 mol / L thioacetamide. During stirring, add 4.5 mL of 2.4 mol / L hydrochloric acid dropwise to obtain 30 mL of solution A. The pH value is 4.5;

[0095] Measure 30mL of absolute ethanol, and add the absolute ethanol dropwise to solution A at a rate of 1mL / min while stirring continuously to form solution B;

[0096] 4.0g of γ-Al with a diameter of 2-5mm 2 o 3 The particles are immersed in 13.0mL mixed aqueous solution containing 0.1mol / L nickel nitrate and 0.4mol / L urea, heat-treated at 70°C for 18 hours, filtered, washed and then dried at 130°C for 2 hours, in 100mL / min air flow at 550 ℃ roasting for 2 hours to obtain Ni-modified alumina carrier Z-2, the grid density of Z-2 is listed in Table 2;

[0097] Transfer the solution B to the autoclave filled with the alumina carrier Z-2 prepared above, then place the autoclave in a rotary oven (rotating at 80 rpm) and contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com