Vulcanization method for hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, which are used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. consumption, improve utilization, and give full play to the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A kind of decomposition and vulcanization method of gasoline hydrodesulfurization catalyst

[0034] Step 1. The gasoline hydrogenation catalyst loaded with active components is only dried to remove free water in the catalyst. The drying temperature is 120°C, and the drying time is not less than 600 minutes. After drying, cool to room temperature and directly carry out catalyst loading according to the process requirements. Packed into the hydrogenation reactor;

[0035] Step 2. Preparation of vulcanized oil: fresh straight-run naphtha is added with 2% carbon disulfide of its mass to prepare vulcanized oil. After the vulcanized oil is mixed with hydrogen, the temperature is raised to the temperature required by the process through a heat exchanger and enters the hydrogenation reactor;

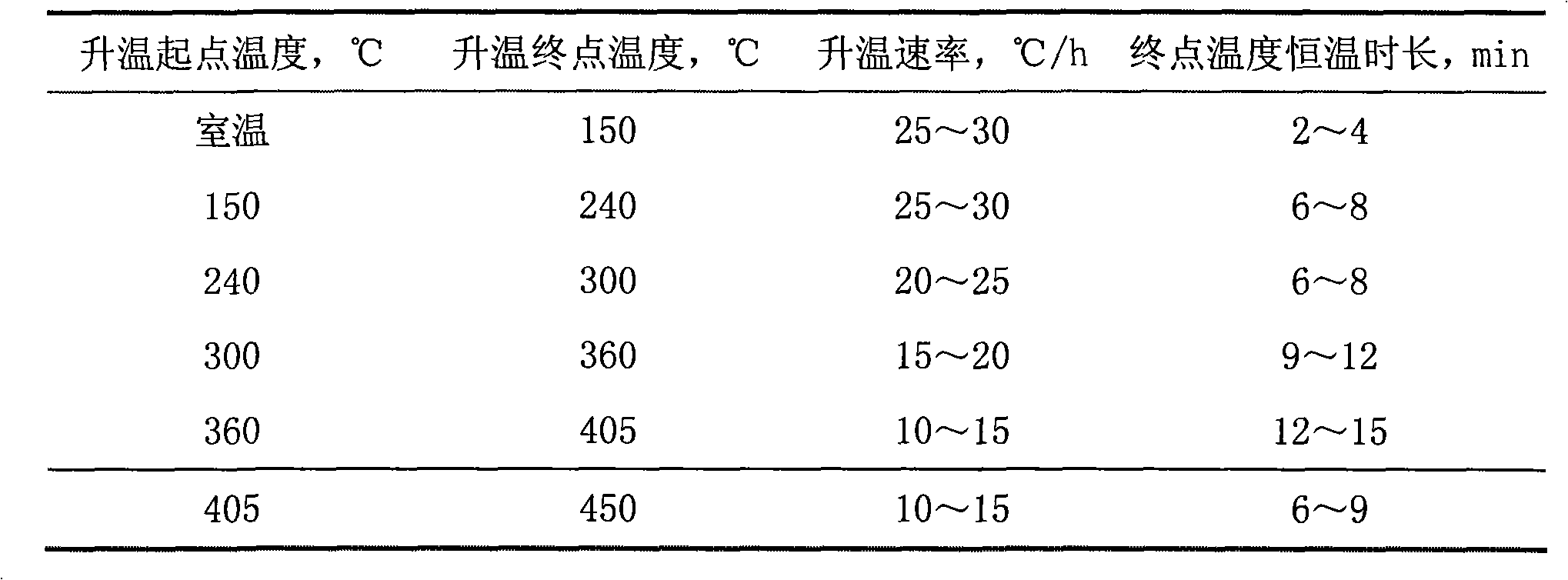

[0036] Step 3. Maintain the temperature of the hydrogenation reactor at the decomposition and vulcanization temperature of the catalyst. The decomposition and vulcanization t...

Embodiment 2

[0052] Embodiment 2. A method for decomposition and vulcanization of a diesel hydrodesulfurization catalyst

[0053] Step 1. Only dry the catalyst loaded with active components to remove free water in the catalyst. The drying temperature is 120°C-150°C, and the drying time is 600min. In the hydrogenation reactor;

[0054] Step 2. Preparation of vulcanized oil: fresh straight-run kerosene is added with 4% carbon disulfide by mass to prepare vulcanized oil. After the vulcanized oil is mixed with hydrogen, it is heated to the temperature required by the process through a heat exchanger and enters the hydrogenation reactor;

[0055] Step 3. Maintain the temperature of the hydrogenation reactor at the decomposition and vulcanization temperature of the catalyst. The decomposition and vulcanization temperature range of the catalyst is 150-450°C. Program the temperature rise according to the process requirements, and keep the temperature stable at different temperature points. Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com