Pre-sulfurization method of hydrogenation catalyst

A hydrogenation catalyst and pre-sulfiding technology, which is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult to control the degree of sulfidation and long sulfidation time, and achieve a controllable degree of pre-sulfurization. , high degree of vulcanization, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

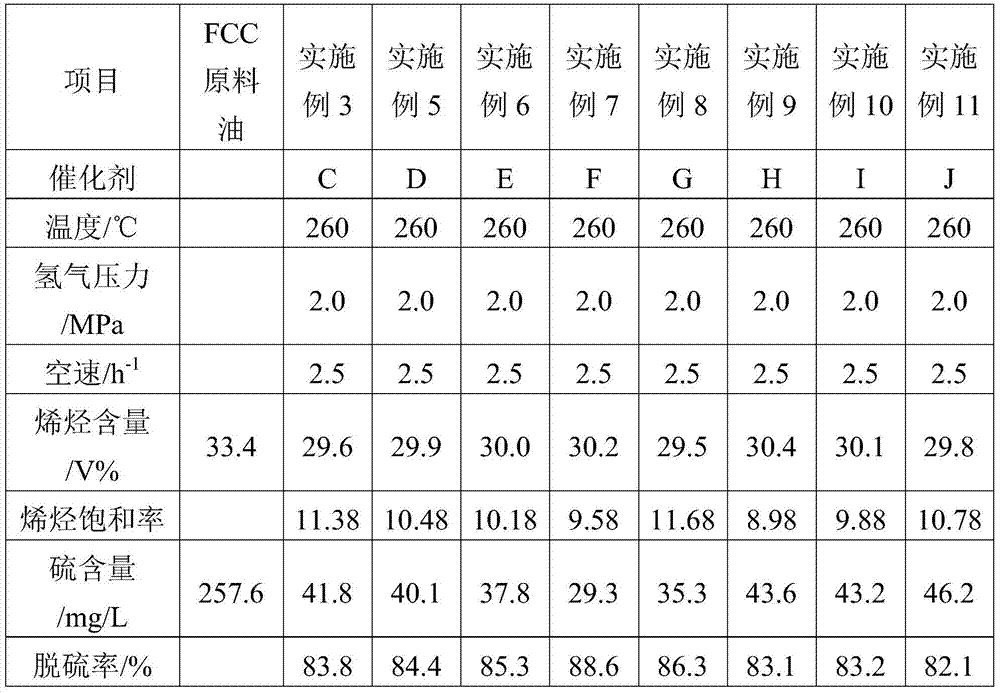

Examples

preparation example Construction

[0025] The concrete steps of the preparation method of hydrogenation catalyst of the present invention and presulfurization treatment method are as follows:

[0026] (1) Preparation of catalyst carrier:

[0027] Using alumina carrier, according to the molding method of conventional carrier, knead aluminum hydroxide powder into strip or granular shape, dry and roast to make particles of certain shape and size;

[0028] (2) Loading of active component metals:

[0029] Prepare a solution of the soluble oxygen-containing salt of Group VIB metal Mo or W and Group VIII metal Co or Ni, impregnate the carrier prepared in step (1) by equal volume impregnation method or saturated impregnation method, and heat at 80-140°C Dry for 2 to 16 hours;

[0030] (3) Pre-vulcanization:

[0031] Presulfurize the catalyst impregnated with soluble oxygen-containing salt prepared in step (2), add hydrogenation catalyst, hydrogenation active gas and one or more sulfur-containing compounds into the r...

Embodiment 1

[0034] Embodiment 1: the preparation of catalyst carrier

[0035] Weigh 100g of aluminum hydroxide powder, add 2.2g of scallop powder, mix well, add 70ml of 2wt% nitric acid aqueous solution for acid activation, fully knead into a gel, and extrude it into a clover with a diameter of 2.0mm on an extruder Shaped strips were dried in an oven at 110° C. for 10 hours to obtain a dry carrier. Then, the obtained carrier was broken into strips, and the strips with a length of 3-5 mm were taken and calcined in an air atmosphere at 550° C. in a muffle furnace for 4 hours to obtain a catalyst carrier A.

Embodiment 2

[0036] Embodiment 2: preparation of supported Mo, Co metal catalyst

[0037] Weigh 11g of ammonium molybdate tetrahydrate, add 30ml of deionized water and 15ml of ammonia water, stir and dissolve, then add 3.3g of cobalt nitrate, stir and dissolve to form a solution. Use this solution to impregnate 100 g of the carrier A prepared in Example 1. After the impregnation, put it in an oven at 110°C and dry it for 10 hours, and place the dried catalyst in a muffle furnace at 500°C for 4 hours to obtain the carrier A loaded with Mo, Co metal catalyst B, the catalyst MoO 3 , CoO loadings are: 10wt% and 3wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com