Vulcanized hydrogenation catalyst, preparation method therefor and application thereof

A technology of hydrogenation catalyst and sulfide state, which is applied in the field of preparation of sulfide state hydrogenation catalyst, and can solve the problem of low sulfide degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

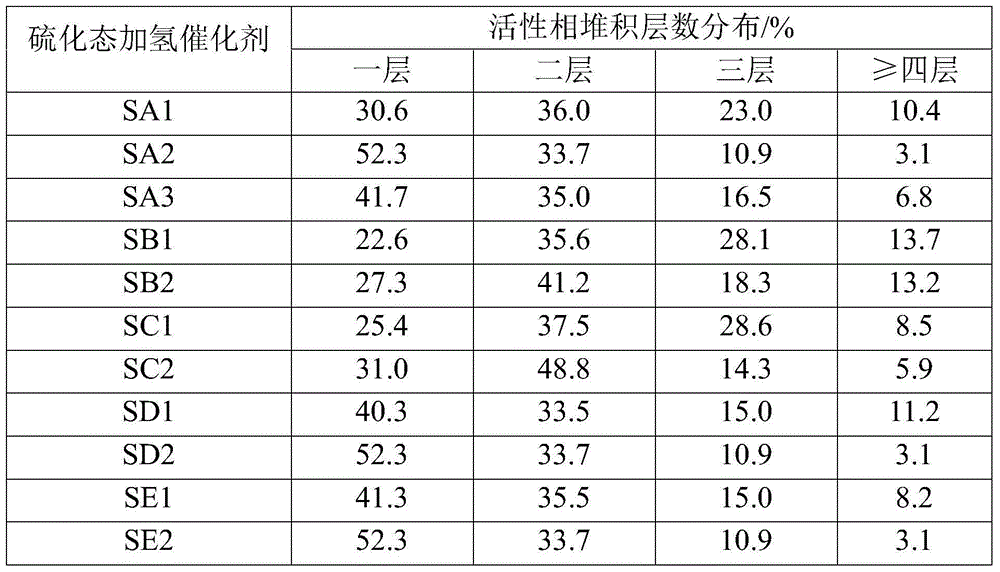

Examples

preparation example Construction

[0025] The preparation method of the sulfurized state hydrogenation catalyst provided by the invention comprises the following steps:

[0026] (1) Prepare an oxidized state hydrogenation catalyst, the oxidized state hydrogenation catalyst includes a carrier and an organic alcohol compound and an active metal oxide supported on the carrier, and the organic alcohol compound exists at 200-400°C at least one exothermic peak;

[0027](2) In the presence of a vulcanization medium, the temperature of the hydrogenation catalyst in the oxidized state is sequentially raised from room temperature at a rate of 1-20°C / h to each release temperature of the organic alcohol compound between 200-400°C; Constant temperature vulcanization at the temperature corresponding to the heat peak peak value for 1-5 hours, and then increase the temperature at a rate of 1-20°C / h from the highest exothermic peak peak value of the organic alcohol compound between 200-400°C The corresponding temperature is in...

Embodiment 1

[0046] This example is used to illustrate the sulfided hydrogenation catalyst provided by the present invention and its preparation method.

[0047] Prepare oxidation state hydrogenation catalyst A1 according to a conventional method, which includes alumina carrier and NiO and MoO supported on alumina carrier 3 Active metal components and ethylene glycol, wherein the molar ratio of carbon atoms to Ni metal atoms in the oxidation state hydrogenation catalyst A1 is 2:1, based on the total weight of the oxidation state hydrogenation catalyst, NiO and MoO 3 The mass content is respectively 3% and 15%. Oxidized state hydrogenation catalyst A1 can decompose and release CO at 230°C-295°C and 300°C-400°C through the temperature-programmed oxidation method (heating rate is 10°C / min, the same below). 2 , CO 2 The temperatures corresponding to the release peaks were 260°C and 350°C, respectively. The oxidized state hydrogenation catalyst A1 is vulcanized by a dry vulcanization method,...

Embodiment 2

[0055] This example is used to illustrate the sulfided hydrogenation catalyst provided by the present invention and its preparation method.

[0056] Oxidation state hydrogenation catalyst B1 was prepared according to a conventional method, which included an alumina support and NiO and WO supported on the alumina support. 3 Active metal components and ethylene glycol, wherein the molar ratio of carbon atoms to Ni metal atoms in the oxidation state hydrogenation catalyst B1 is 2:1, based on the total weight of the oxidation state hydrogenation catalyst, NiO and WO 3 The mass content is respectively 2.5% and 20.5%. Oxidation hydrogenation catalyst B1 can decompose and release CO at temperatures between 200°C-295°C and 300°C-400°C as measured by the temperature-programmed oxidation method 2 , CO 2 The temperatures corresponding to the release peaks were 260°C and 350°C, respectively. The oxidized state hydrogenation catalyst B1 is vulcanized by a dry vulcanization method, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com