A kind of preparation method of sulfurized hydrogenation catalyst

A hydrogenation catalyst, sulfurized technology, applied in the field of preparation of sulfurized hydrogenation catalyst, can solve the problems of incompleteness, high cost, strengthening the interaction between hydrogenation components and carriers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

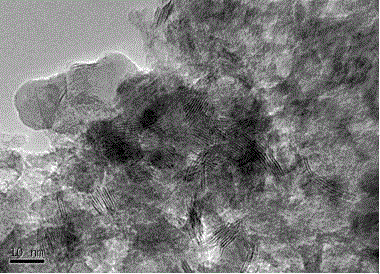

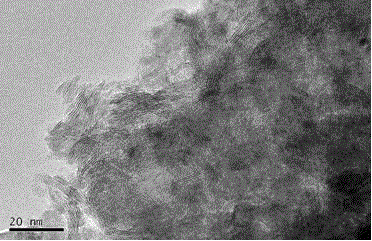

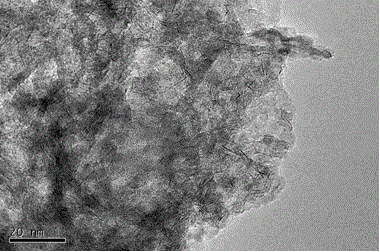

Image

Examples

Embodiment 1

[0028] The catalyst catA involved in the present invention. Weigh 120g amorphous silicon aluminum, 33gY molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 40, the unit cell constant is 2.432nm, the infrared acidity is 0.19mmol / g, and the specific surface area is 866m 2 / g, pore volume 0.52ml / g), 48g of nickel nitrate and 67g of ammonium tetrathiomolybdate were put into the roller compactor and mixed evenly, then added 180g of viscose made by peptizing nitric acid and SB alumina The mixture is kneaded and rolled to make extrudable paste and extruded into strips. Under the protection of nitrogen, the catalyst catA was obtained by drying at 120°C for 6 hours and calcining at 500°C for 4 hours.

Embodiment 2

[0030] The catalyst catB involved in the present invention. Weigh 125g of amorphous silicon aluminum, 33gY molecular sieve (the properties are the same as in Example 1), 40g of nickel nitrate and 94g of tetrathioammonium tungstate, put them into a roller compactor and mix them evenly, then add 180g of nitric acid and SB alumina The adhesive made by peptization is kneaded and rolled to make extrudable paste and extruded into strips. Under the protection of nitrogen, the catalyst catB was obtained by drying at 110°C for 6 hours and calcining at 480°C for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com