Bio-oil hydrodeoxygenation method

A technology for hydrodeoxygenation and bio-oil, which is applied in the fields of biological raw materials, chemical instruments and methods, and preparation of liquid hydrocarbon mixtures, can solve the problems of easy aggregation and deactivation of catalyst active phases, poor hydrothermal stability, etc. Active phase dispersibility, not easy to run off, and the effect of improving sulfur fixation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

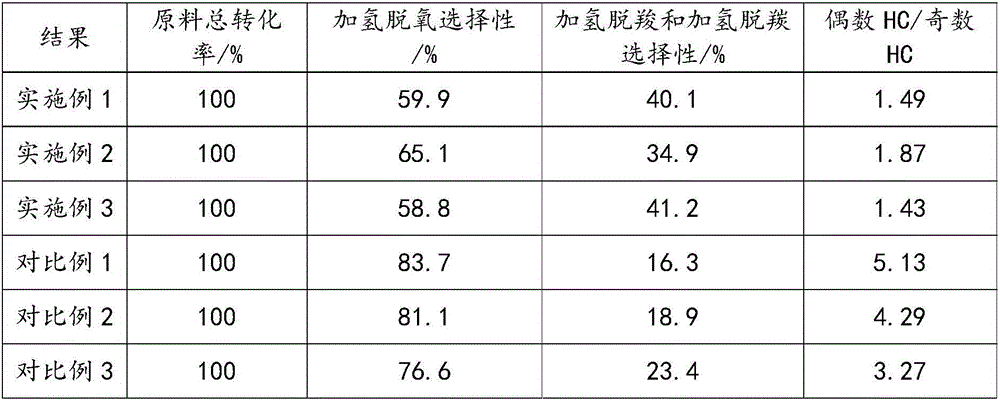

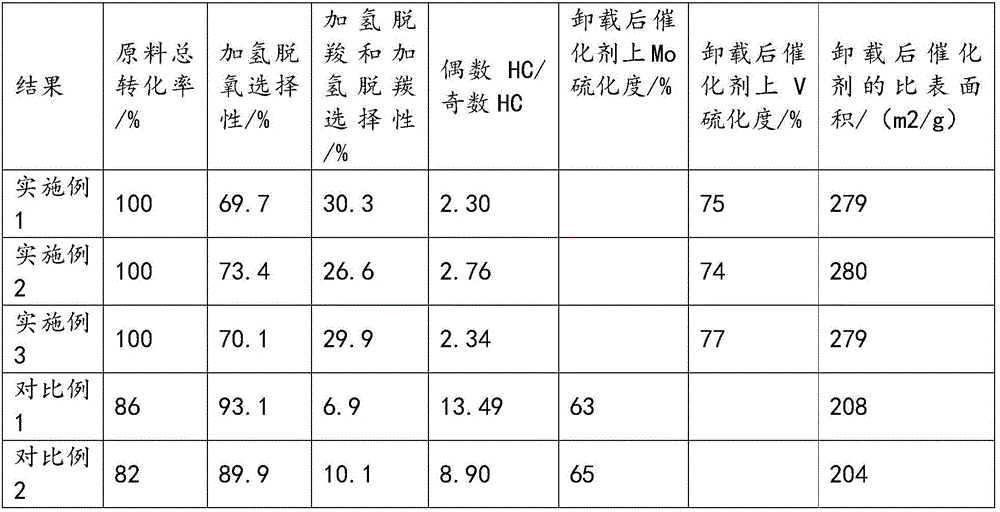

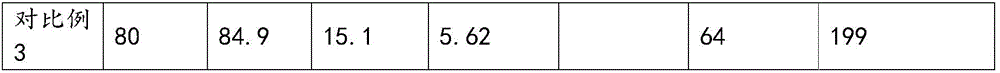

Examples

Embodiment 1

[0040] (1) Preparation of oxidation state catalyst:

[0041] Take by weighing 1000 grams of dry rubber powder and 30 grams of safflower powder and mix them evenly, then add 900 milliliters of aqueous solution containing 28 g of nitric acid, and extrude them into cylindrical wet bars with an outer diameter of φ1.4 mm on a plunger extruder. Then the cylindrical wet strip was dried at 120°C for 4 hours, and then calcined at 600°C for 3 hours to obtain carrier Z with a pore volume of 0.62mL / g and a specific surface area of 280m 2 / g.

[0042] Add 50g of ammonium metavanadate, 50g of manganese carbonate and 1000g of citric acid into 400mL of aqueous solution, heat and stir until completely dissolved to obtain 500mL of impregnation solution. Take 400g of the above-mentioned carrier Z, spray all the above-mentioned impregnating liquid evenly on the carrier Z, then put the obtained semi-dry catalyst into an oven and dry it at 120°C for 4 hours, and then place it in a ventilated tub...

Embodiment 2

[0051] (1) Preparation of oxidation state catalyst:

[0052] Take by weighing 1000 grams of dry rubber powder and 30 grams of safflower powder and mix them evenly, then add 900 milliliters of aqueous solution containing 28 g of nitric acid, and extrude them into cylindrical wet bars with an outer diameter of φ1.4 mm on a plunger extruder. Then the cylindrical wet strip was dried at 120°C for 4 hours, and then calcined at 600°C for 3 hours to obtain carrier Z with a pore volume of 0.62mL / g and a specific surface area of 280m 2 / g.

[0053] Add 28g of ammonium metavanadate and 18g of manganese carbonate into 350mL of citric acid aqueous solution, heat and stir until the ammonium metavanadate and citric acid are completely dissolved to obtain 500mL of impregnation solution. The same method as in Example 1 was used to impregnate the support Z to obtain the hydrodeoxygenation catalyst C2.

[0054] (2) Pretreatment before vulcanization

[0055] Phosphoric acid is selected as th...

Embodiment 3

[0061] (1) Preparation of oxidation state catalyst:

[0062] Take by weighing 1000 gram of dry rubber powder and 30 gram of asparagus powder and mix homogeneously, then add 900 milliliters of the aqueous solution that contains 28g nitric acid, extrude into the cylindrical wet strip of outer diameter φ 1.4mm on the plunger extruder. Then the cylindrical wet strip was dried at 120°C for 4 hours, and then calcined at 600°C for 3 hours to obtain carrier Z with a pore volume of 0.62mL / g and a specific surface area of 280m 2 / g.

[0063] Add 60g of ammonium metavanadate and 70g of manganese carbonate into 350mL of aqueous solution, heat and stir until the ammonium metavanadate and citric acid are completely dissolved to obtain 500mL of impregnation solution. The same method as in Example 1 was used to impregnate the carrier Z to obtain the hydrodeoxygenation catalyst C3.

[0064] (2) Pretreatment before vulcanization

[0065] Phosphoric acid is selected as the VA oxygen-contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com