Presulfurized sulfur-tolerant shift catalyst and preparation method

A sulfur-resistant shift, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the temporary or permanent loss of catalyst activity, incomplete catalyst vulcanization , catalyst bed flying temperature and other problems, to achieve the effect of good conversion activity and stability, good economic benefits and application prospects, and easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

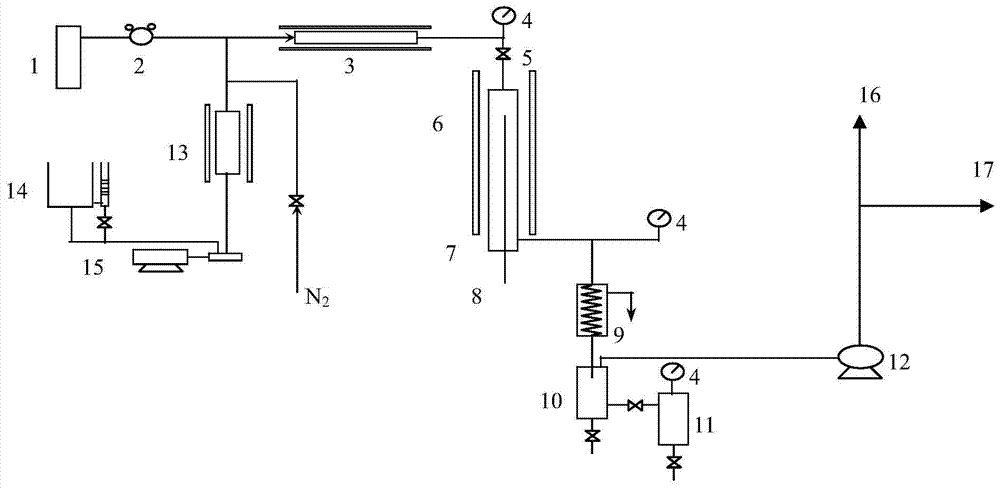

Method used

Image

Examples

Embodiment 1-7

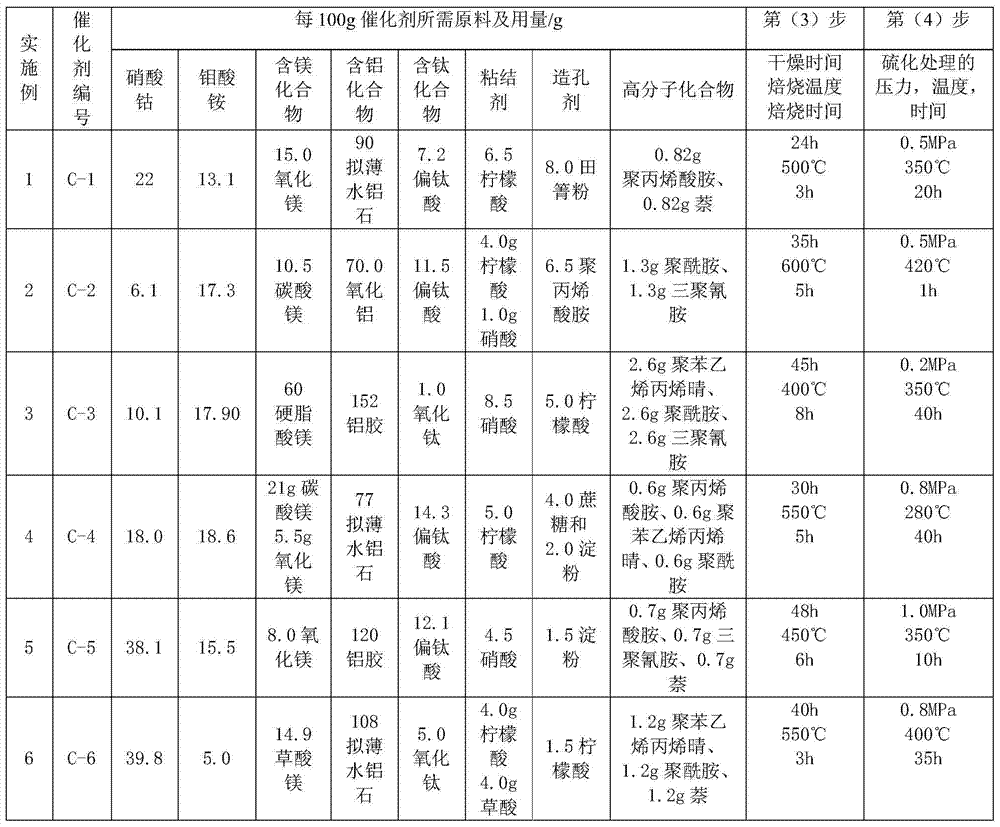

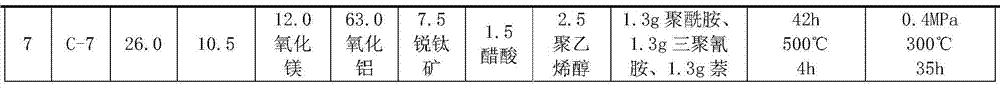

[0054] Catalysts C1-C7 are prepared by kneading method, active components, carrier materials, pore-forming agent and binder are mixed, shaped, dried, roasted, pre-sulfurized, and passivated to obtain finished catalysts.

[0055] Cobalt-containing compounds, with Co 8 o 9 In terms of molybdenum-containing compounds, as MoS 2 in terms of; magnesium-containing compounds, in terms of MgO; aluminum-containing compounds, in terms of Al 2 o 3 In terms of; titanium-containing compounds, as TiO 2 High carbon molecular compounds, in terms of C, the specific composition is shown in Table 1.

[0056] Concrete preparation steps are as follows:

[0057] (1) Preparation of active component solution:

[0058] Dissolve ammonium molybdate with deionized water to obtain solution A; dissolve cobalt nitrate with deionized water, then add binder into it, stir and dissolve to obtain solution B.

[0059] (2) Catalyst molding:

[0060] Mix the magnesium-containing powdery solid compound, alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com