Rubber sealing ring used for GIS composite apparatus and production method thereof

A technology of rubber sealing rings and combined electrical appliances, applied in the field of rubber materials, can solve problems such as low compression permanent deformation, and achieve the effects of long service life, long vulcanization time and uniform vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

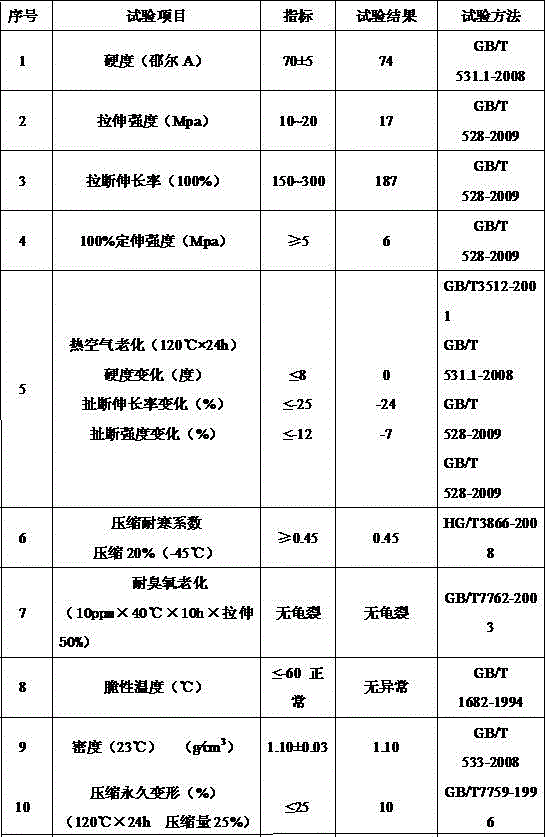

[0022] The rubber sealing ring for GIS combined electrical appliances is made of the following raw materials by weight: 100 parts of EPDM rubber; 5 parts of zinc oxide; 1 part of stearic acid; 25 parts of high wear-resistant carbon black; 30 parts of spray carbon black 6 parts of dioctyl sebacate; 1 part of antioxidant MB; 2.5 parts of vulcanizing agent BIPB.

[0023] The preparation method comprises the following steps:

[0024] (1) Weighing and batching according to the above ratio, and then put the weighed EPDM raw rubber into the internal mixer for 5 minutes to make the raw rubber obtain sufficient fluidity;

[0025] (2) Add zinc oxide, stearic acid, carbon black and other raw materials except vulcanizing agent to the above plasticized raw rubber, and continue banburying for 10 minutes to ensure that various raw materials are mixed evenly;

[0026] (3) Take out the mixed rubber material from the internal mixer, put it into the open mixer and pass it 5 times, so that the r...

Embodiment 2

[0029] The rubber sealing ring for GIS combined electrical appliances is made of the following raw materials by weight: 100 parts of EPDM rubber; 5 parts of zinc oxide; 1 part of stearic acid; 20 parts of high wear-resistant carbon black; 30 parts of spray carbon black ; 8 parts of dioctyl sebacate; 0.5 parts of antioxidant MB; 2.5 parts of vulcanizing agent BIPB.

[0030] The preparation method comprises the following steps:

[0031] (1) Weighing and batching according to the above ratio, and then put the weighed EPDM raw rubber into the mixer for 3 minutes to make the raw rubber obtain sufficient fluidity;

[0032] (2) Add zinc oxide, stearic acid, carbon black and other raw materials except vulcanizing agent to the above-mentioned plasticized raw rubber, and continue banburying for 5 minutes to ensure that various raw materials are mixed evenly;

[0033] (3) Take out the mixed rubber material from the internal mixer, put it into the open mixer and pass it through for 3 tim...

Embodiment 3

[0036] A rubber sealing ring for GIS combined electrical appliances, made of the following raw materials in parts by weight: 100 parts of EPDM rubber; 3 parts of zinc oxide; 2 parts of stearic acid; 20 parts of high wear-resistant carbon black; spray carbon black 30 parts; 8 parts of dioctyl sebacate; 1 part of antioxidant MB; 2 parts of vulcanizing agent BIPB.

[0037] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com