Modified alumina carrier and preparation method thereof

An alumina carrier and alumina technology, which is applied in the field of oil hydrogenation, can solve the problems of no significant increase in the amount of B acid, catalyst carbon deposition poisoning and deactivation, and reduced catalyst stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

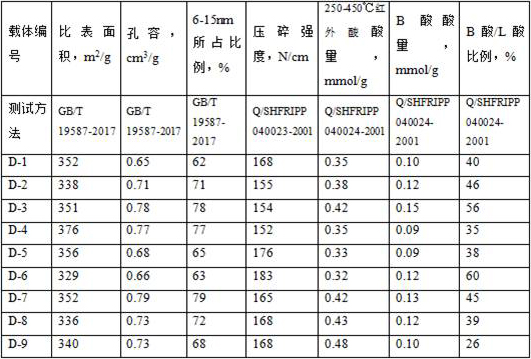

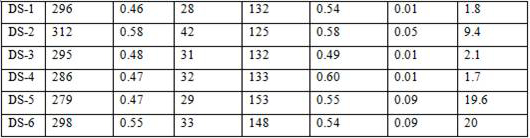

Examples

Embodiment 1

[0023]Add 9.5g of phosphoric acid into the reaction tank and place 1 L of deionized water as the bottom liquid, put 1 L of aluminum sulfate solution (concentration of 1mol / L) and 1 L of sodium hydroxide solution (concentration of 3.0mol / L) in In the raw material tank, the temperature of the reaction tank is controlled at 65°C. The aluminum sulfate solution was injected into the reaction tank at a rate of 12 mL / min, while the sodium hydroxide solution was injected and the rate was adjusted to keep the pH value of the reaction tank solution at 8.0, and the neutralization was completed after 120 min. Keep 65°C and pH constant at 8.0 in the reaction tank, aging treatment for 3h, washing with deionized water for 3 times, filtering, placing the filter cake in a 500ml solution containing 27.7g magnesium nitrate and 100g urea, fully stirring, and then Hydrothermal treatment at 150°C for 10 hours, filtration and drying at 120°C for 3 hours to obtain modified pseudo-boehmite.

[0024] ...

Embodiment 2

[0026] Add 20g of phosphoric acid into the reaction tank and place 1 L of deionized water as the bottom liquid, and place 1 L of aluminum sulfate solution (concentration of 1mol / L) and 1 L of sodium hydroxide solution (concentration of 3.0mol / L) in the raw material In the tank, the temperature of the reaction tank is controlled at 65°C. The aluminum sulfate solution was injected into the reaction tank at a rate of 12 mL / min, while the sodium hydroxide solution was injected and the rate was adjusted to keep the pH value of the reaction tank solution at 8.0, and the neutralization was completed after 120 min. Keep 65°C and pH constant at 8.0 in the reaction tank, aging treatment for 3h, washing with deionized water for 3 times, filtering, placing the filter cake in a 500ml solution containing 27.7g magnesium nitrate and 100g urea, fully stirring, and then Hydrothermal treatment at 150°C for 10 hours, filtration and drying at 120°C for 3 hours to obtain modified pseudo-boehmite. ...

Embodiment 3

[0029] Add 28.6g of phosphoric acid into the reaction tank and place 1 L of deionized water as the bottom liquid, put 1 L of aluminum sulfate solution (concentration of 1mol / L) and 1 L of sodium hydroxide solution (concentration of 3.0mol / L) in In the raw material tank, the temperature of the reaction tank is controlled at 65°C. The aluminum sulfate solution was injected into the reaction tank at a rate of 12 mL / min, while the sodium hydroxide solution was injected and the rate was adjusted to keep the pH value of the reaction tank solution at 8.0, and the neutralization was completed after 120 min. Keep 65°C and pH constant at 8.0 in the reaction tank, aging treatment for 3h, washing with deionized water for 3 times, filtering, placing the filter cake in a 500ml solution containing 27.7g magnesium nitrate and 100g urea, fully stirring, and then Hydrothermal treatment at 150°C for 10 hours, filtration and drying at 120°C for 3 hours to obtain modified pseudo-boehmite.

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com