A kind of alumina-based hydrorefining catalyst and its preparation method and application

A hydrorefining, alumina-based technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of increasing dispersibility and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

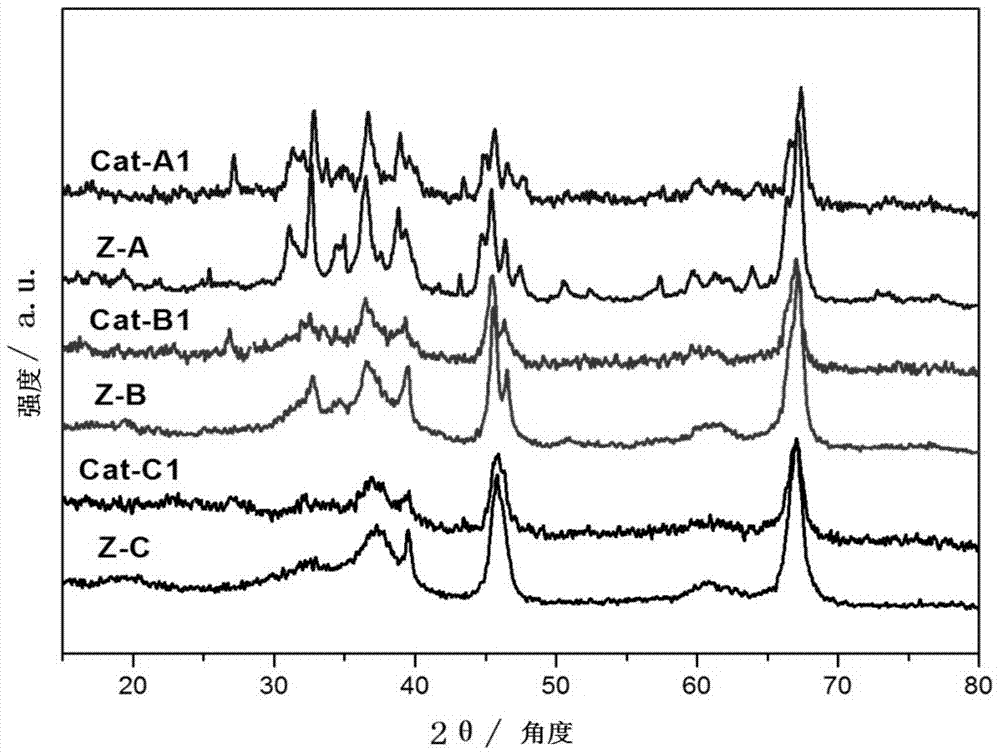

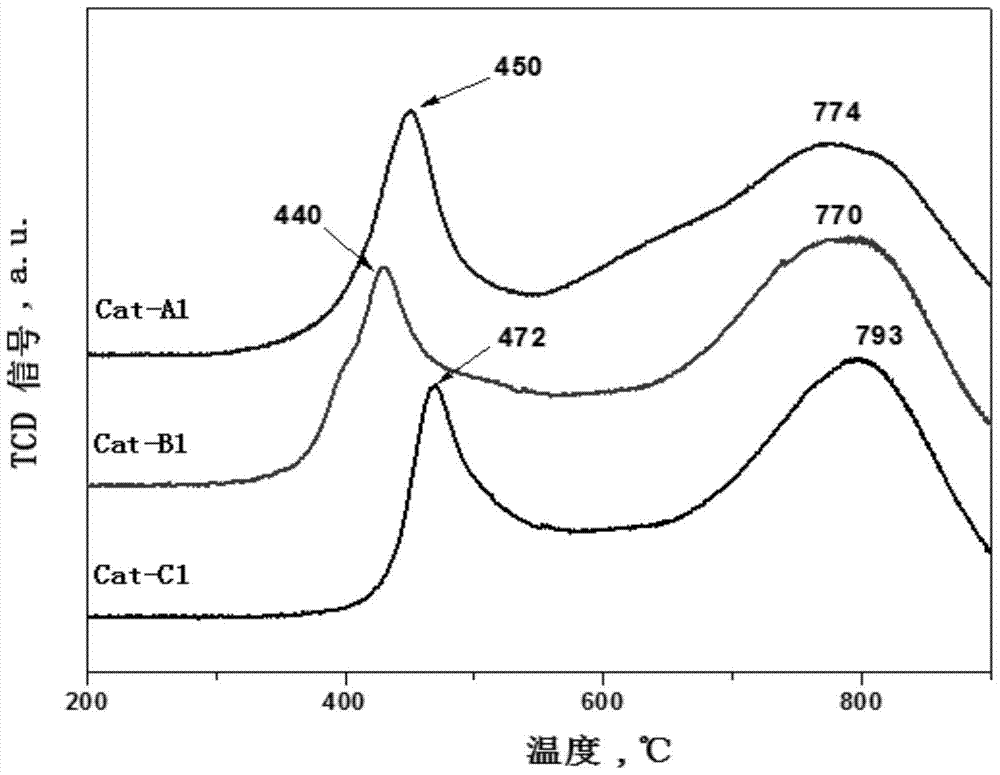

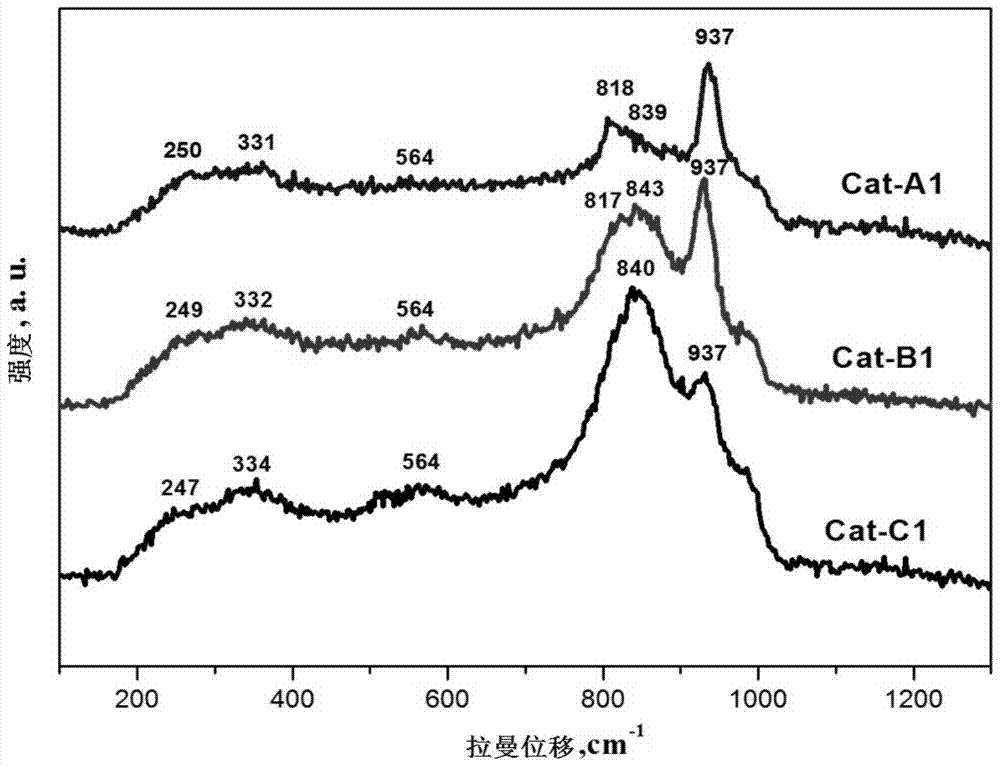

[0041] This embodiment provides an alumina-based hydrofinishing catalyst for FCC diesel, the preparation method of which comprises the following steps:

[0042] After mixing 30g of bomite powder and 1g of scallop powder, add 1g of concentrated nitric acid, 0.8g of phosphoric acid and an appropriate amount of water dropwise; after fully back-mixing in the extruder, extrude into a cylindrical shape with a diameter of 1.5mm; Dry at 110°C for 2 hours; then heat up to 1050°C at 2°C / min and bake at constant temperature for 6 hours to obtain θ-Al 2 o 3 Carrier (specific surface area is 121m 2 g -1 , the pore diameter is 20.5nm, the pore volume is 0.77cm 3 g -1 );

[0043] First, 6.6g of ammonium molybdate dissolved in 30g of water was used to impregnate θ-Al 2 o 3 Carrier, ultrasonically dispersed for 20 minutes, stirred for 5 minutes, dried at 110°C for 2h, calcined at 550°C for 6 hours, cooled to room temperature; then 4.5g of cobalt sulfate dissolved in 30g of water was use...

Embodiment 2

[0046] This embodiment provides an alumina-based hydrofinishing catalyst for FCC diesel, the preparation method of which comprises the following steps:

[0047] The preparation of catalyst carrier material and step-by-step impregnation of active metal in this embodiment are the same as in Example 1;

[0048] Dissolve 9.4g of EDTA in 30g of ammonia solution with a pH of 9, co-impregnate the catalyst loaded with cobalt and molybdenum, dry at 110°C for 6 hours, break or cut into required lengths according to the process requirements, and the carrier used is recorded as Z-A, the corresponding catalyst is recorded as Cat-A2.

Embodiment 3

[0050] This embodiment provides an alumina-based hydrofinishing catalyst for FCC diesel, the preparation method of which comprises the following steps:

[0051] Prepared by the method of Example 1 to obtain θ-Al 2 o 3 Carrier, first impregnated θ-Al with 6.6g ammonium molybdate dissolved in 30g water 2 o 3 Carrier, then ultrasonically disperse it for 20 minutes, stir for 5 minutes, dry at 110°C for 2h, bake at 550°C for 6 hours, and cool to room temperature; then dissolve 4.5g of cobalt sulfate in 30g of water to co-impregnate molybdenum-loaded θ -Al 2 o 3 Carrier, dried at 110°C for 2 hours, and calcined at 550°C for 6 hours;

[0052] Dissolve 3.1g of NTA in 30g of ammonia solution with a pH of 9, co-impregnate the catalyst loaded with cobalt and molybdenum, and dry at 110°C for 6 hours. According to the process requirements, it is broken or cut into the required length. The corresponding catalyst is recorded as Cat-A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com