Low-hardness NBR (nitrile-butadiene rubber) sealing element material for automobile transmission converters and preparation method thereof

A technology for automobile gearboxes and converters, applied in the field of rubber seals, can solve the problems of ozone resistance and high resilience performance that cannot meet the ideal use requirements, and achieve the effects of refined preparation process, good oil resistance, and good temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

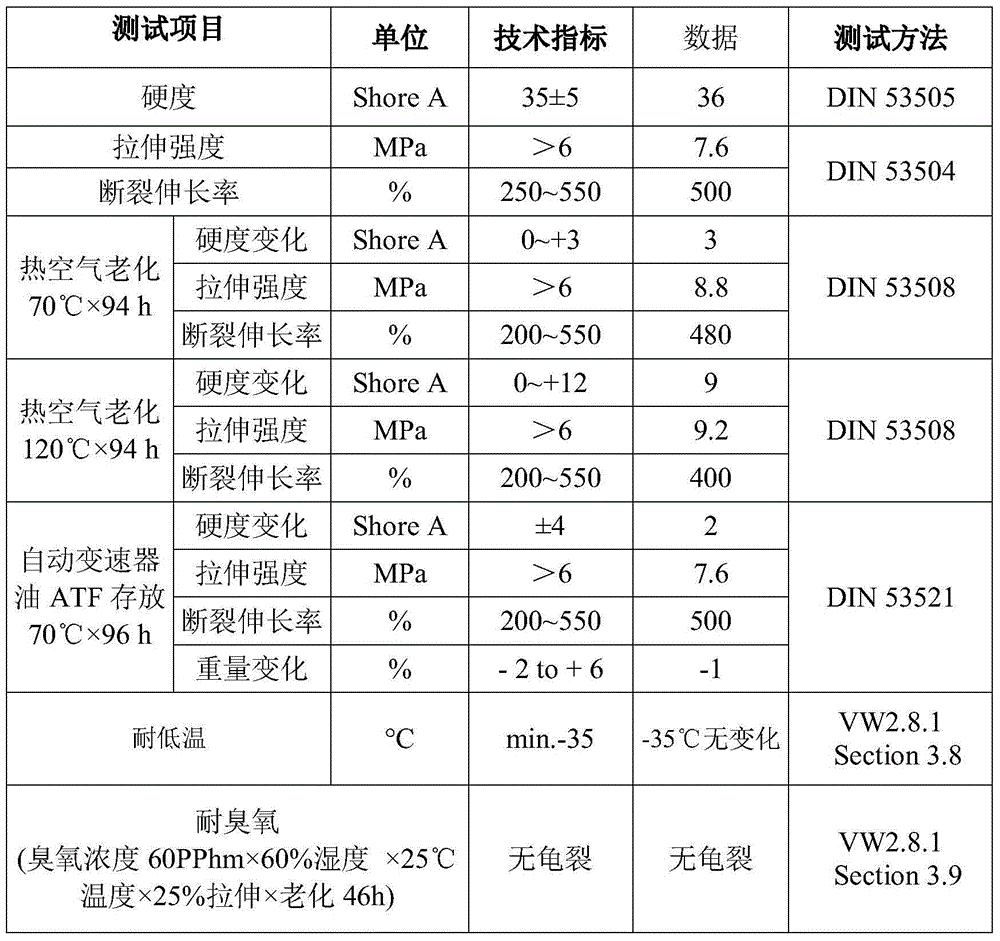

Embodiment 1

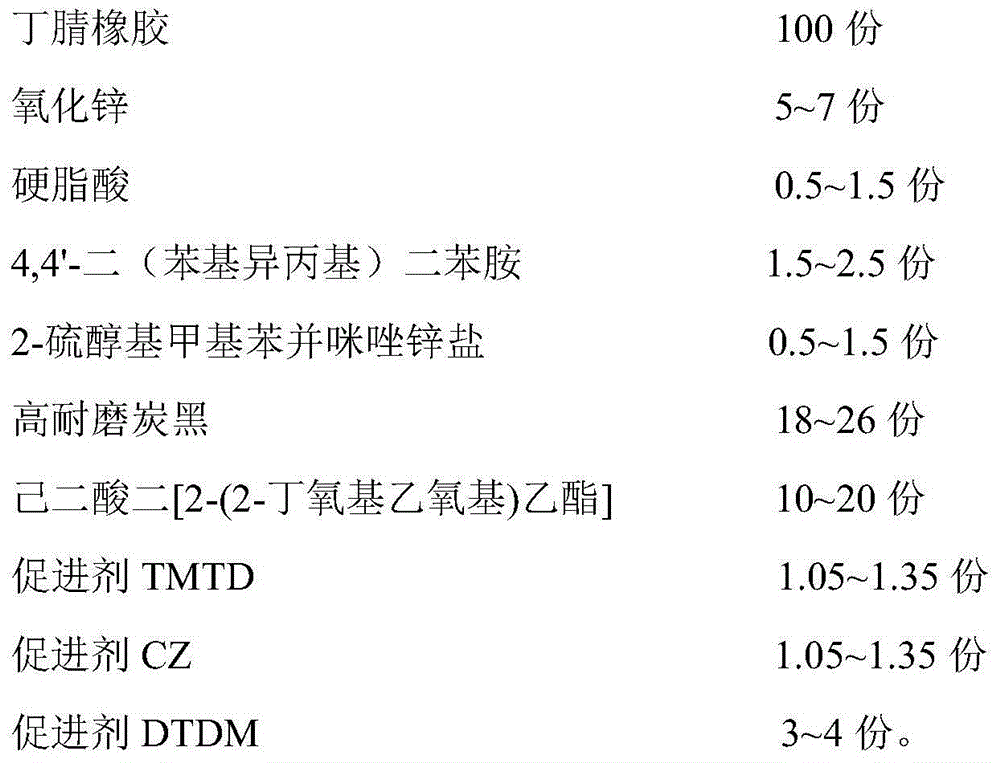

[0026] A kind of low-hardness NBR seal material for automobile transmission converter of the present embodiment, its mass ratio is as follows: 100 parts of nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 4,4'-bis(phenyl 2 parts of isopropyl) diphenylamine, 1 part of 2-mercaptomethylbenzimidazole zinc salt, 22 parts of high wear-resistant carbon black, bis[2-(2-butoxyethoxy) ethyl adipate Esters] 15 parts, accelerator TMTD 1.2 parts, accelerator CZ 1.2 parts, accelerator DTDM 3.5 parts.

[0027] Acrylonitrile-butadiene rubber is filled with 50 parts of liquid acrylonitrile-butadiene rubber in the present embodiment, and acrylonitrile content is 31.5%, and the Mooney viscosity ML (1+4) 100 ℃ of 100 ℃ is the nitrile-butadiene rubber of DN223 that Ruion company produces; Zinc is the indirect zinc oxide produced by Zhenjiang Baishui Chemical Co., Ltd.; stearic acid is produced by Malaysia Southern Oil Company; the supplier of bis[2-(2-butoxyethoxy)ethyl adipate] is S...

Embodiment 2

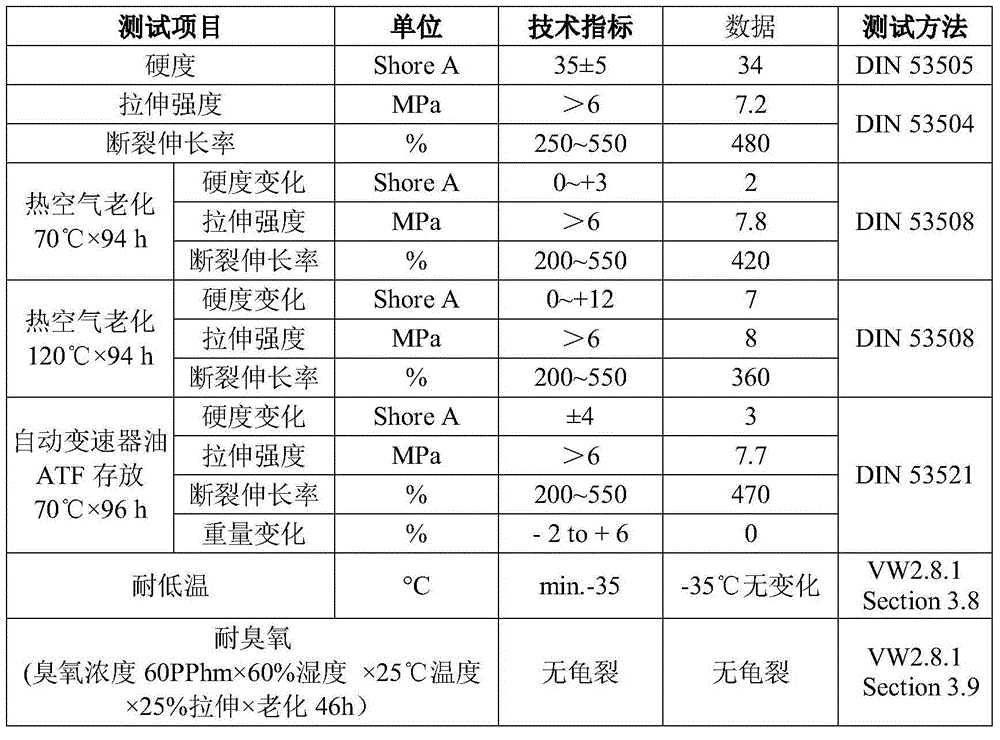

[0036] A kind of low-hardness NBR seal material for automobile transmission converter of the present embodiment, its mass ratio is as follows: 100 parts of nitrile rubber, 7 parts of zinc oxide, 1.5 parts of stearic acid, 4,4'-di(phenyl 2.5 parts of isopropyl) diphenylamine, 0.5 parts of 2-mercaptomethylbenzimidazole zinc salt, 18 parts of high wear-resistant carbon black, bis[2-(2-butoxyethoxy) ethyl adipate Esters] 10 parts, accelerator TMTD 1.05 parts, accelerator CZ 1.35 parts, accelerator DTDM 3 parts.

[0037] The source of each component raw material of this embodiment is identical with embodiment 1.

[0038] The process of preparing the low-hardness NBR seal material for the automotive gearbox converter in this embodiment is as follows:

[0039] Step 1, preparation of master batch rubber: prepare materials according to the above formula, and send all raw materials except accelerator TMTD and accelerator DTDM into the internal mixer to obtain master batch rubber;

[0...

Embodiment 3

[0045] A kind of low-hardness NBR seal material for automobile transmission converter of the present embodiment, its mass ratio is as follows: 100 parts of nitrile rubber, 6 parts of zinc oxide, 0.5 part of stearic acid, 4,4'-di(phenyl 1.5 parts of isopropyl) diphenylamine, 1.5 parts of 2-mercaptomethylbenzimidazole zinc salt, 26 parts of high wear-resistant carbon black, bis[2-(2-butoxyethoxy) ethyl adipate Esters] 20 parts, accelerator TMTD 1.35 parts, accelerator CZ 1.05 parts, accelerator DTDM 4 parts.

[0046] The source of each component raw material of this embodiment is identical with embodiment 1.

[0047] The process of preparing the low-hardness NBR seal material for the automotive gearbox converter in this embodiment is as follows:

[0048] Step 1, preparation of master batch rubber: prepare materials according to the above formula, and send all raw materials except accelerator TMTD and accelerator DTDM into the internal mixer to obtain master batch rubber;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com