Domestic gas hose, processing process thereof and special-purposed production device thereof

A technology for gas hoses and production equipment, applied in the directions of hoses, mechanical equipment, pipes, etc., can solve the problems of insufficient material supply and normal production, and achieve the effect of ensuring smooth material supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The invention provides a household gas hose, which consists of the following components in parts by weight:

[0045] NBR: 40;

[0046] PVC: 60;

[0047] Cross-linking agent: 0.6;

[0048] Stabilizer: 6;

[0049] Plasticizer: 30;

[0050] Reinforcing Filler: 40;

[0051] And it is mixed and extruded by the above-mentioned components. Under the distribution ratio of the components, the use performance and processing performance of the household gas hose are optimized.

Embodiment 2

[0053] A processing technology of the household gas hose of embodiment 1, comprising the steps of:

[0054] NBR preprocessing step A:

[0055] First, add a quantitative ratio of stabilizers, plasticizers and reinforcing fillers to NBR for mixing.

[0056] Add a crosslinking agent to the NBR after mixing for pre-crosslinking (semi-vulcanization),

[0057] Grinding the pre-crosslinked NBR into uniform small particles;

[0058] PVC pretreatment step B:

[0059] Add stabilizers, plasticizers, and reinforcing fillers in quantitative proportions to PVC, and knead and plasticize them in a high-speed mixer. At this time, the PVC mixture is in the form of loose powder;

[0060] The NBR particles pretreated in step A and the PVC plastic compound pretreated in step B are added to a high-speed mixer at a weight ratio of NBR:PVC of 40:60, mixed, preheated, and then extruded.

Embodiment 3

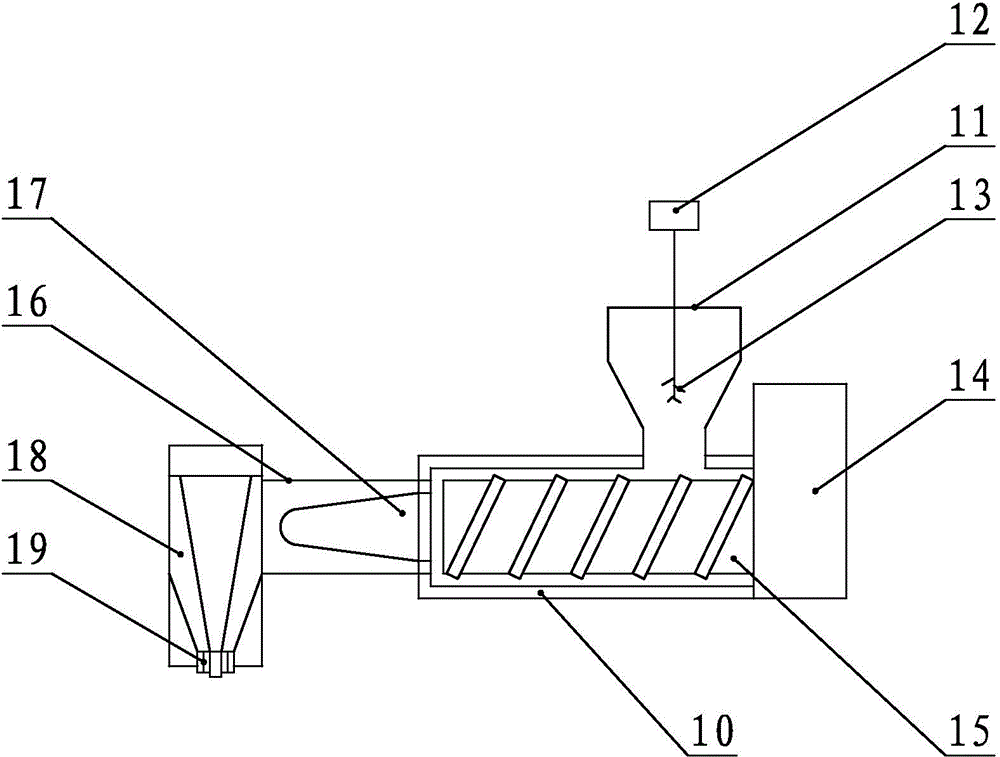

[0062] refer to figure 1, a special production equipment for household gas hoses based on Embodiment 2, including an extrusion cylinder 10, a hopper 11 arranged at the inlet end of the extrusion cylinder 10, a propeller 13 and a driving propeller 13 arranged in the hopper 11 The feeding motor 12, the extrusion screw 15 that is axially arranged in the extrusion cylinder 10, the extrusion motor 14 that is arranged at one end of the extrusion cylinder 10 and drives the extrusion screw 15, and the extrusion motor 14 that is arranged at the exit of the extrusion cylinder 10 Extrusion port 19 at the end.

[0063] Wherein, the outlet end of the extrusion barrel 10 is provided with a T-shaped head 18 with a trapezoidal extrusion channel, and the extrusion port 19 is located at the outlet end of the T-shaped head 18 at the end of the extrusion channel with a smaller radius.

[0064] Wherein, a heating tube 16 is arranged between the T-shaped head 18 and the extrusion barrel 10, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com