Fluoride rubber and plastic sealing material and preparation method thereof

A sealing material and fluororubber technology, applied in the field of special rubber and its preparation, can solve the problems of great influence on stability and high cost of fluororubber, and achieve the effects of stable properties, easy operation and retention of original characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Weigh 40kg of fluorine rubber; 1kg of calcium silicate; 15kg of carbon black; 5kg of magnesium oxide; 0.5kg of triethylenediamine, and 5kg of calcined clay.

[0019] b. Put the fluororubber in the internal mixer, under the condition of 150 ℃, masticate for 4 minutes; add carbon black, 1 / 3 of the amount of magnesium oxide, 1 / 3 of the amount, masticate for 8 minutes; then add the rest Magnesium oxide and calcium silicate, masticated for 6 minutes, shut down, turned over and discharged, and cooled to below 65°C for use;

[0020] c. Put the above-mentioned materials in an open mill, and add triethylenediamine under the condition of ≤65°C. After eating the materials, pass them thinly for 4 times, put on triangular bags for 5 times, and remove the slices.

Embodiment 2~6

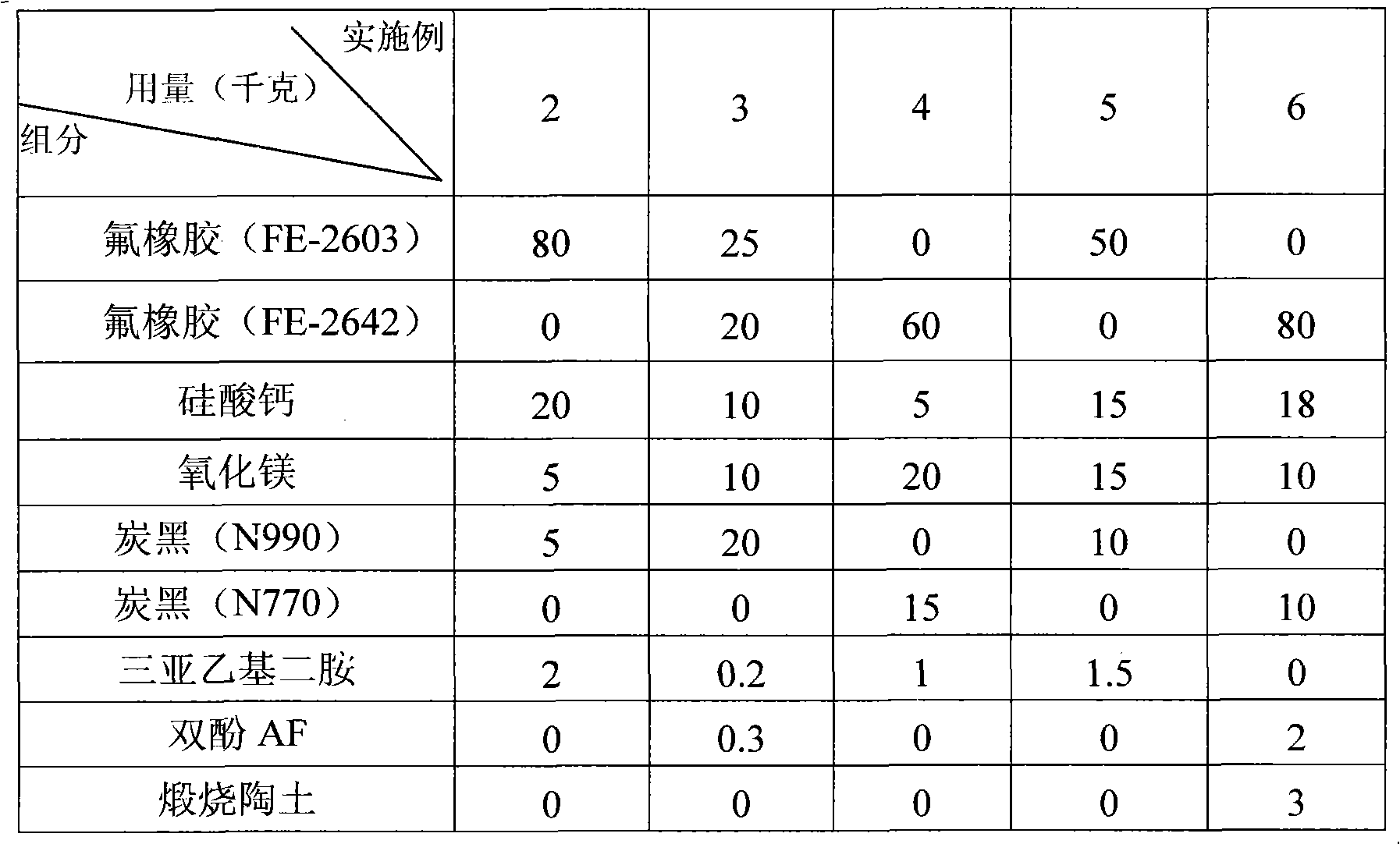

[0021] Embodiment 2~6 (see table 1)

[0022] Preparation method Example 1 is basically the same. Just formula consumption and process condition are different, but all within the scope described in the method of the present invention.

[0023] Table 1

[0024]

[0025] The beneficial effects of the present invention have been verified by the following test data (see Table 2 for details).

[0026] Vulcanization condition 175℃×4min Second stage 160℃×4h

[0027] Table 2

[0028] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com