Halogen-free flame retardant insulating material for photovoltaic cables

A photovoltaic cable and insulating material technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of cable insulation material performance degradation, intermolecular chemical bond breakage, loss of polymer properties, etc., to achieve reasonable component distribution and equipment Less, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

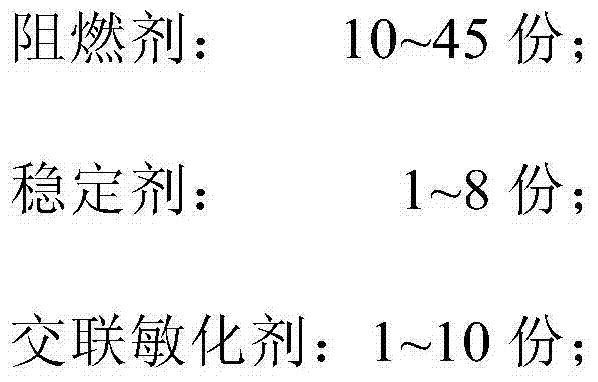

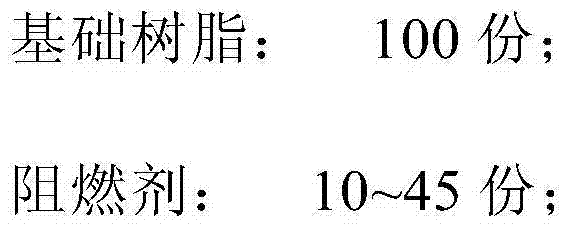

[0043] Each component name and each component parts by weight are as follows:

[0044]

[0045] The preparation method of the above-mentioned invention comprises the following processing steps:

[0046] Mix the flame retardant aluminum hydroxide, magnesium hydroxide, zinc borate, silicon dioxide, and expandable graphite in a high-speed mixer according to the proportion at high speed until the temperature reaches 110°C, add zinc stearate and stir for 3-6 minutes. Place the material, and mix it with high-density polyethylene, ethylene-methyl methacrylate copolymer, and additives except for the crosslinking agent triallyl isocyanurate, using an internal mixer for 10-15 minutes according to the proportioning ratio. The raw material is extruded and granulated with a twin-screw extrusion granulator of Nanjing Ruiya Polymer Equipment Co., Ltd. while it is hot, to obtain a masterbatch. The masterbatch is mixed with the cross-linking agent triallyl isocyanurate in proportion to wat...

Embodiment 2

[0048] Each component name and each component parts by weight are as follows:

[0049]

[0050]

[0051] The preparation method of the above-mentioned invention comprises the following processing steps:

[0052] Mix the flame retardant aluminum hydroxide, magnesium hydroxide, zinc borate, silicon dioxide, and expandable graphite in a high-speed mixer according to the proportion at high speed until the temperature reaches 110°C, add zinc stearate and stir for 3-6 minutes. The material is placed, and the high-density polyethylene, ethylene-methyl methacrylate copolymer, ethylene-vinyl acetate copolymer, and additives other than the crosslinking agent triallyl isocyanurate are used in an internal mixer according to the ratio. Preliminarily blend for 10-15 minutes to discharge the material, and extrude and granulate the material while it is hot with a twin-screw extrusion granulator of Nanjing Ruiya Polymer Equipment Co., Ltd. to obtain a masterbatch. The masterbatch is mix...

Embodiment 3

[0054] Each component name and each component parts by weight are as follows:

[0055]

[0056]

[0057] The preparation method of the above-mentioned invention comprises the following processing steps:

[0058] Mix the flame retardant aluminum hydroxide, magnesium hydroxide, zinc borate, silicon dioxide, and expandable graphite in a high-speed mixer according to the proportion at high speed until the temperature reaches 110°C, add zinc stearate and stir for 3-6 minutes. The material is placed, and the high-density polyethylene, ethylene-methyl methacrylate copolymer, ethylene-vinyl acetate copolymer, and additives other than the crosslinking agent triallyl isocyanurate are used in an internal mixer according to the ratio. Preliminarily blend for 10-15 minutes to discharge the material, and extrude and granulate the material while it is hot with a twin-screw extrusion granulator of Nanjing Ruiya Polymer Equipment Co., Ltd. to obtain a masterbatch. The masterbatch is mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com