Brake cable for electric vehicle

A technology of brake lines and electric vehicles, applied in the field of brake lines, can solve the problems of high friction of rubber tubes and steel cables, damage of rubber tubes, etc., and achieve the effects of good elasticity, reduced friction, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

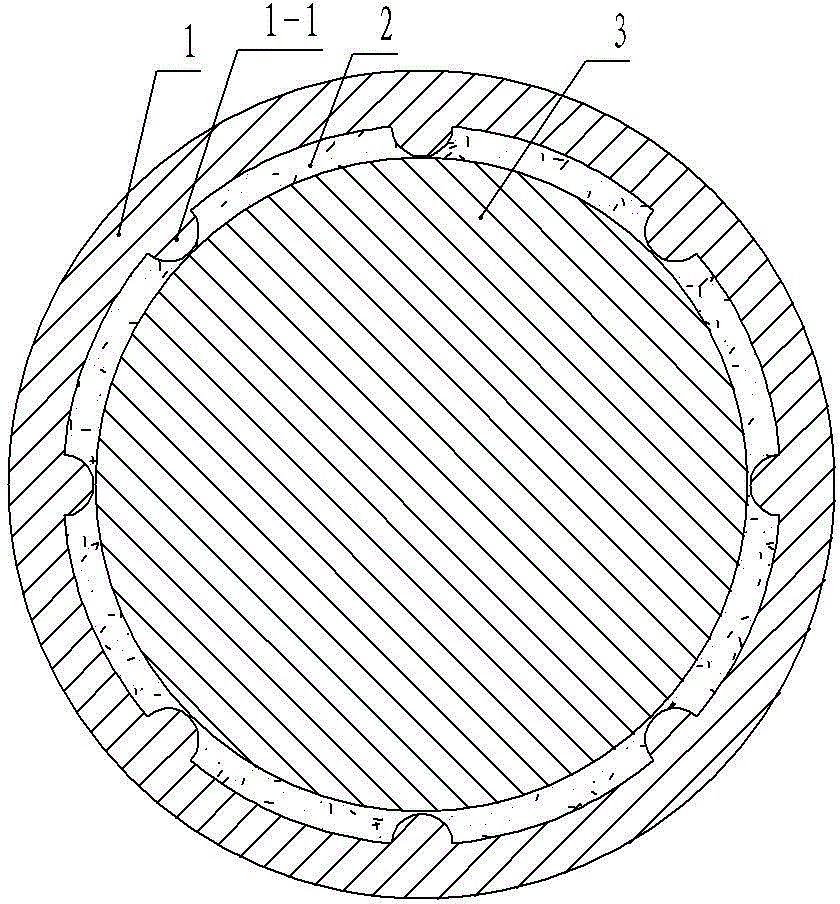

[0013] figure 1 The electric vehicle brake line shown includes a rubber tube 1 made of neoprene material and a steel cable 3 installed in the rubber tube 1. The inner wall of the rubber tube 1 is provided with a plurality of radial projections 1-1, A lubricating substance 2 is filled between the rubber tube 1 and the steel cable 3, and the lubricating substance 2 is lubricating grease. The brake line of the present invention has the functions of high strength, long life, corrosion resistance and light weight, and at the same time reduces the contact surface between the rubber tube and the steel cable sheath, thereby reducing the friction between the two, ensuring that the rubber tube not be damaged.

Embodiment 2

[0015] The rubber tube 1 is made of ethylene-propylene rubber; the lubricant 2 is talcum powder; the rest are the same as the first embodiment.

Embodiment 3

[0017] The rubber tube 1 is made of polyurethane rubber; the rest are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com