Formula and preparation method of inner glue in chlorinated polyethylene rubber tube

A technology for chlorinated polyethylene and polyethylene hoses, which can be used in hoses, pipes, machinery and equipment, etc., can solve problems such as non-conformity and short service life, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

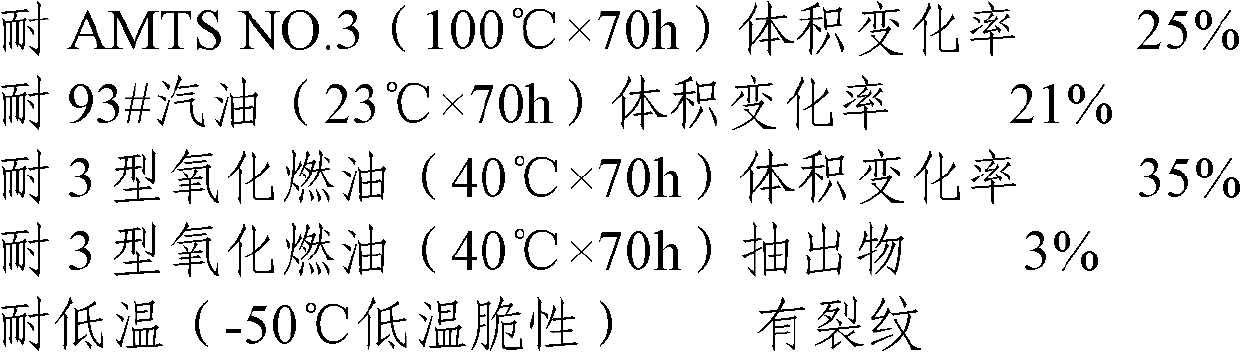

Embodiment 1

[0036] In parts by mass:

[0037] Chlorinated polyethylene (CM) 40 parts,

[0038] 60 parts of alloy glue,

[0039] Anti-aging agent 2 parts,

[0040] Semi-reinforced furnace black N774 60 parts,

[0041] 40 parts of modified nano kaolin,

[0042] 2 parts paraffin,

[0043] Cold-resistant plasticizer DOS 30 parts,

[0044] Magnesium oxide 5 parts,

[0045] Fatty acid amides NC 2 parts,

[0046] Two parts of dimercaptothiazole derivative TDD.

[0047] The first step is to put chlorinated polyethylene (CM) rubber, alloy glue and anti-aging agent into the rubber kneader by weight, keep the temperature at 100°C for 5 minutes, and then put magnesium oxide and paraffin into the kneader in turn. Mix the rubber in the kneader for 2 to 3 minutes, then put the modified nano-kaolin, semi-reinforcing furnace black and cold-resistant plasticizer into the kneader and mix the rubber for 4 to 5 minutes, then discharge the rubber, and beat 6 rolls, cooled to below 60°C for use;

[00...

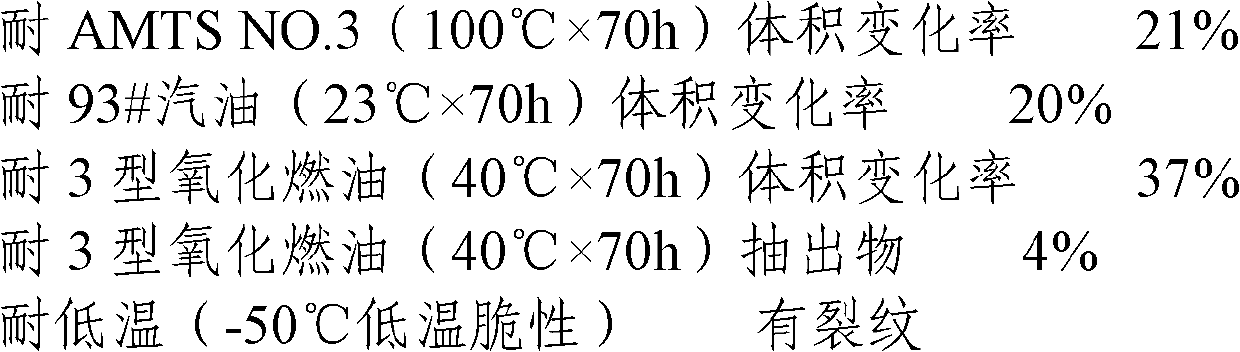

Embodiment 2

[0052] In parts by mass:

[0053] Chlorinated polyethylene (CM) 50 parts,

[0054] 50 parts of alloy glue,

[0055] Anti-aging agent 2 parts,

[0056] Semi-reinforced furnace black N774 60 parts,

[0057] 40 parts of modified nano kaolin,

[0058] 2 parts paraffin,

[0059] Cold-resistant plasticizer DOS 37 parts,

[0060] Magnesium oxide 5 parts,

[0061] Fatty acid amides NC 3 parts,

[0062] Dimercaptothiazole derivative TDD 3 parts.

[0063] The first step is to put chlorinated polyethylene (CM) rubber, alloy rubber and anti-aging agent into the rubber kneader by weight, keep the temperature at 120°C for 4 minutes, and then put magnesium oxide and paraffin into the kneader in turn. Mix the rubber in the kneader for 2 to 3 minutes, then put the modified nano-kaolin, semi-reinforcing furnace black and cold-resistant plasticizer into the kneader and mix the rubber for 4 to 5 minutes, then discharge the rubber, and beat 6 rolls, cooled to below 60°C for use;

[0064]...

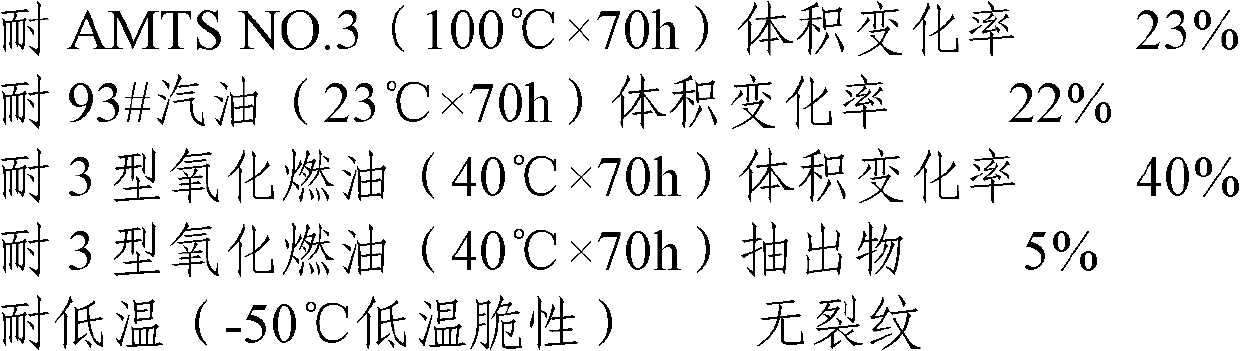

Embodiment 3

[0068] In parts by mass:

[0069] Chlorinated polyethylene (CM) 60 parts,

[0070] 40 parts of alloy glue,

[0071] Anti-aging agent 2 parts,

[0072] Semi-reinforced furnace black N774 60 parts,

[0073] 40 parts of modified nano kaolin,

[0074] 2 parts paraffin,

[0075] Cold-resistant plasticizer DOS 45 parts,

[0076] Magnesium oxide 5 parts,

[0077] Fatty acid amides NC 4 parts,

[0078]Dimercaptothiazole derivative TDD 4 parts.

[0079] The first step is to put chlorinated polyethylene (CM) rubber, alloy glue and anti-aging agent into the rubber kneader by weight, keep the temperature at 110°C for 5 minutes, and then put magnesium oxide and paraffin into the kneader in turn. Mix the rubber in the kneader for 2 to 3 minutes, then put the modified nano-kaolin, semi-reinforcing furnace black and cold-resistant plasticizer into the kneader and mix the rubber for 4 to 5 minutes, then discharge the rubber, and beat 6 rolls, cooled to below 60°C for use;

[0080] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com