High-hardness color ethylene-propylene-diene monomer (EPDM) suitable for microwave vulcanizing and preparation method thereof

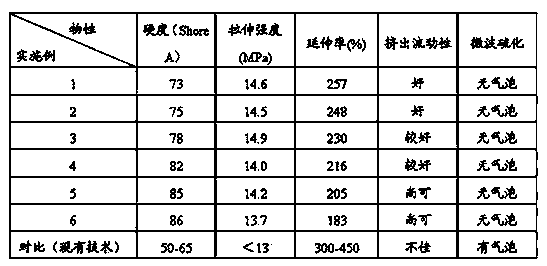

A technology of EPDM rubber and microwave vulcanization, which is applied in the field of rubber, can solve the problems of easy occurrence of air bubbles and insufficient hardness, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0026] Manufacture the high-hardness colored EPDM rubber adapting to microwave vulcanization involved in the present invention according to the following steps:

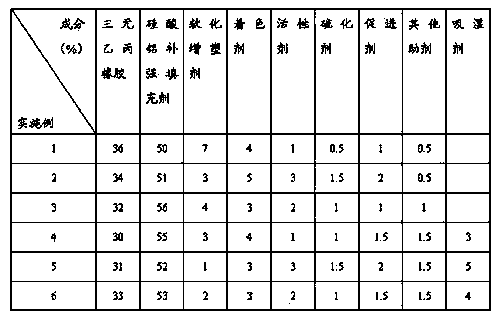

[0027] (1) Material preparation: According to the ratio in Table 1 below, weigh the aluminum silicate reinforcing filler, EPDM rubber and softening plasticizer separately and place them, and mix the colorant, active agent and other additives together to form batch A, and mix vulcanizing agent and accelerator together to form batch B;

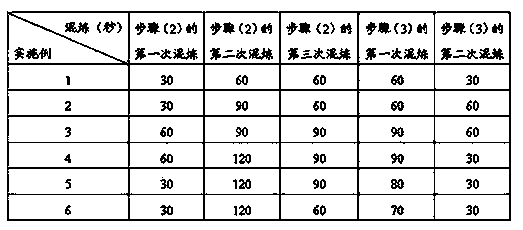

[0028] (2) The first mixing: put EPDM rubber and ingredient A into the internal mixer and mix for 30-60 seconds, then continue to mix with aluminum silicate reinforcing filler and softening plasticizer for 60-120 seconds , and then continue to mix for 60-90 seconds after cleaning, and then unload the material onto the feeder to discharge the sheet to make rubber compound A;

[0029] (3) The second mixing: Put the rubber compound A and ingredients B into the internal mixer and mix for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com