Multifunctional vacuum friction and wear testing machine

A friction and wear test, friction and wear technology, applied in the direction of testing wear resistance, etc., can solve the problems of inconvenient procurement and after-sales service, high market price, short test cycle, short vacuum time, test time and cost consumption reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

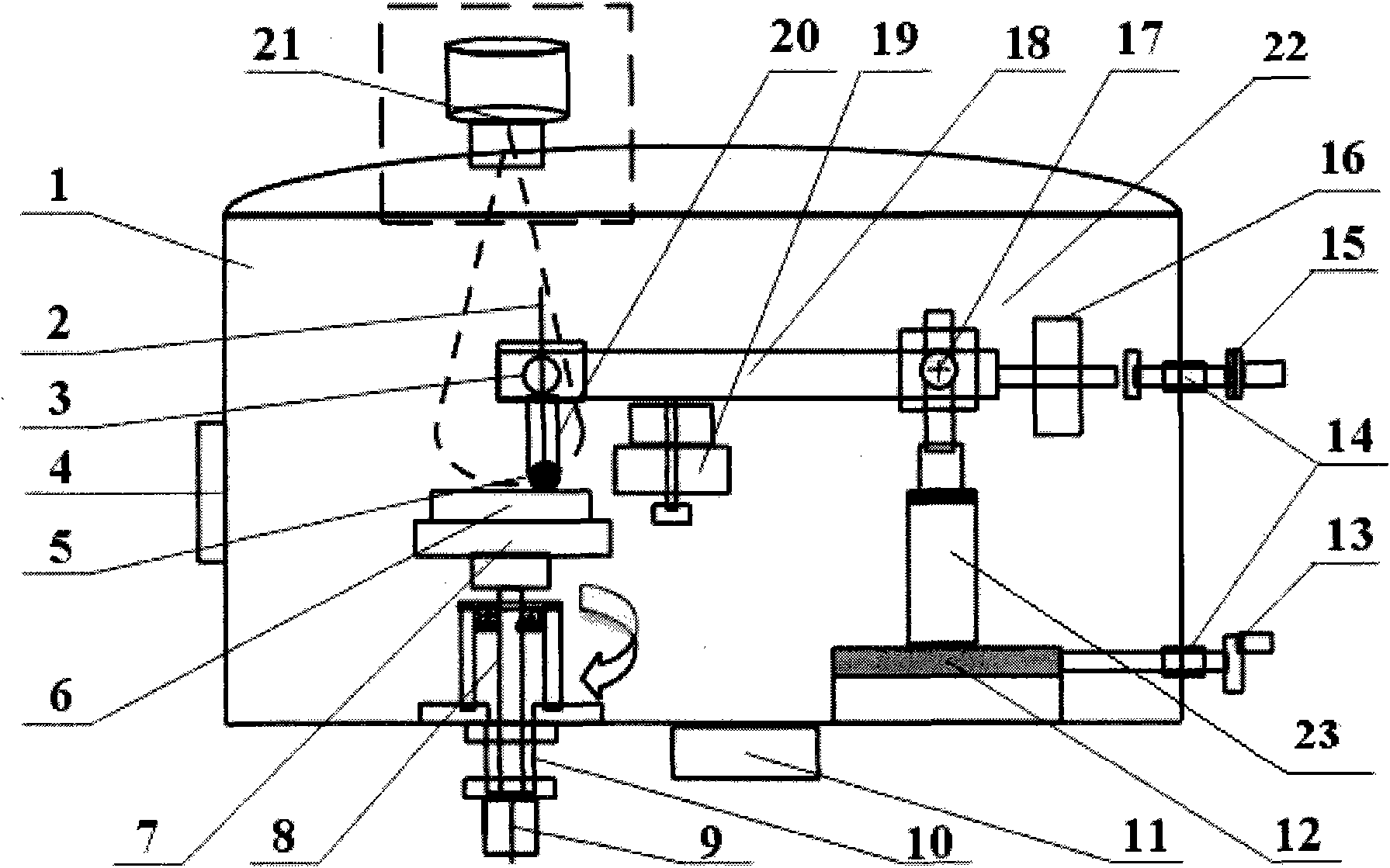

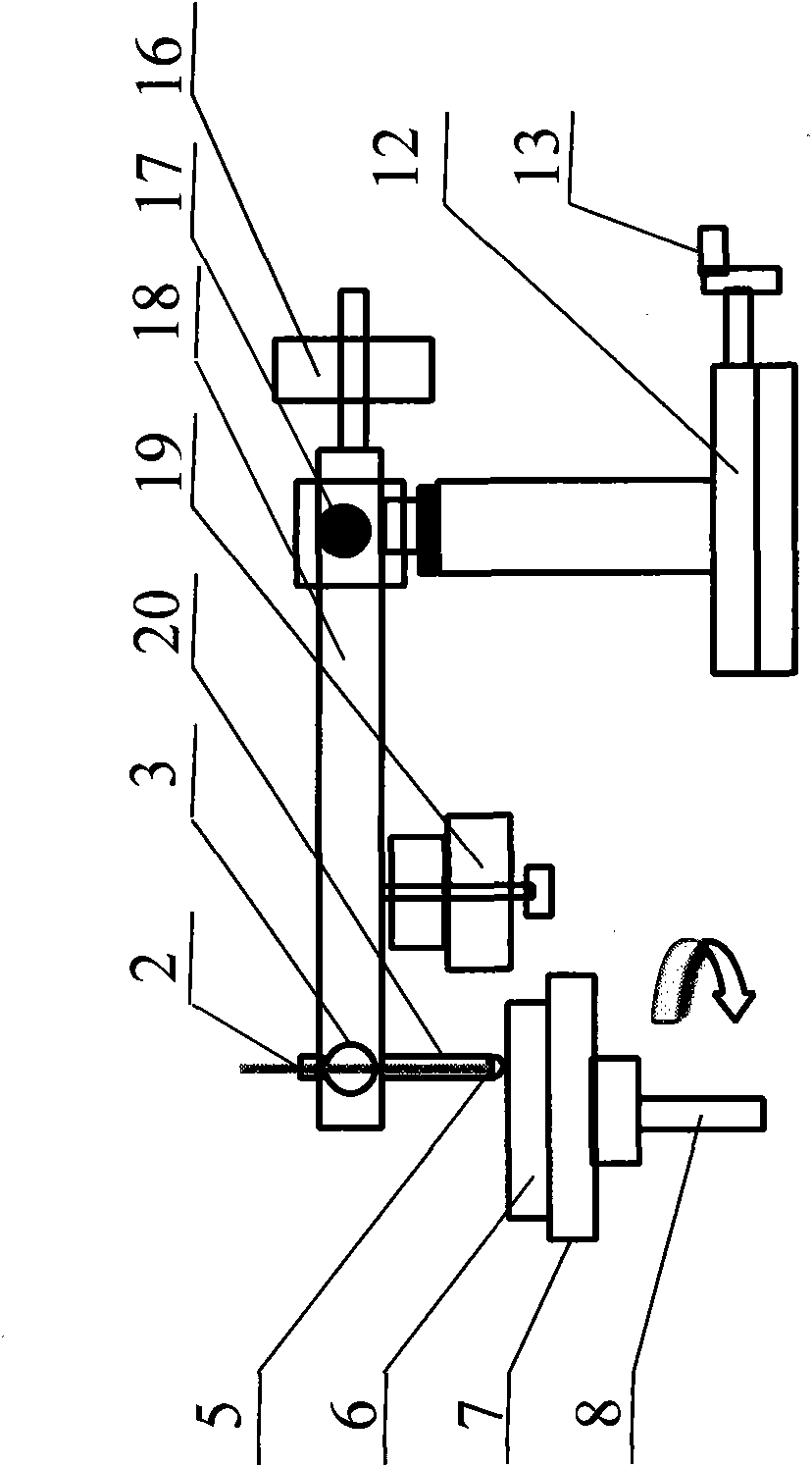

[0027] The testing machine of the present invention is composed of main parts such as a vacuum system, a friction and wear system, a power transmission system, a control system, and a data acquisition and processing system. figure 1 It is a structural schematic diagram of the vacuum friction and wear testing machine of the present invention. Such as figure 1As shown, the vacuum system of the testing machine includes: a vacuum chamber (1), at least one observation window (4) arranged on the side wall of the vacuum chamber (1), a vacuum pump interface flange (11) for connecting a vacuum pump, Spare interface (21), and a plurality of flanges for configuring functional parts, such as flanges for configuring vacuum measuring parts, installing vacuum lighting, equipped with manipulators, venting, etc.; friction and wear system includes: for fixing upper The lever structure (22) of the sample holder (20) is free to rotate in both horizontal and vertical directions. A sample platfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com