Paper diaper pull-up water cooling coating component and method

A technology of water-cooling packs and diapers, applied in medical science, bandages, absorbent pads, etc., can solve the problems of inability to adjust the width of the cladding board and low applicability, and achieve the effect of rapid bonding and precise adjustment of the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

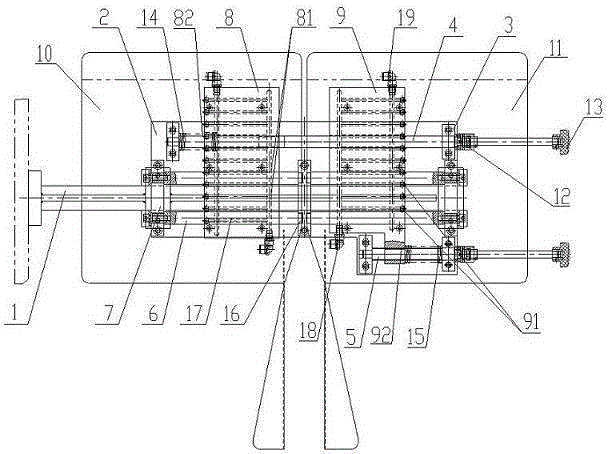

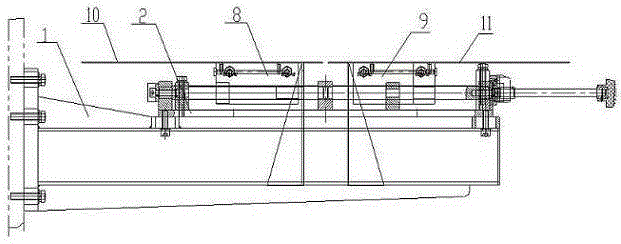

[0010] Embodiment 1: with reference to attached figure 1 with figure 2 . A water-cooled wrapping assembly for diaper protection. The water-cooled support plate 1 8 and the water-cooled support plate 2 9 move along the guide rail 6 under the adjustment of the long adjustment screw 4 and the short adjustment screw 5 respectively. The upper end of the water-cooled support plate 8 is provided with an inner wrapping Plate 10, the upper end of the water-cooled supporting plate 9 is provided with an outer cladding plate 11. The first water-cooling support plate 8 and the second water-cooling support plate 9 are provided with cooling water through-holes 17 distributed in the shape of a "several" and each cooling water through-hole 17 is provided with a water inlet joint 18 at one end and a water outlet at the other end. Connector 19. The surfaces of the cooling water holes 17 in the first water-cooled support plate 8 and the second water-cooled support plate 9 are nano-sprayed sur...

Embodiment 2

[0012] Example 2: On the basis of Example 1, the adjustment and cooling wrapping method of the water-cooled wrapping assembly of the diaper enclosure, (1) the inner wrapping plate 10 and the outer wrapping plate 11 pass the long adjusting screw 4 and the short adjusting screw 5 and digital position display to quickly and accurately adjust the distance between the inner cladding board 10 and the outer cladding board 11 to adapt to the products of the set specifications and sizes; (2) The protective non-woven fabric is cut by the cutting device The back one is divided into two, when passing through the water-cooled support plate one 8, the water-cooled support plate two 9, the protective elastic is cooled rapidly by the cold support plate one 8, the water-cooled support plate two 9 in the wrapping process, so that the rubber band and Wrapping nonwovens bond more quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com