Position adjustable lower die

An adjustable and mold base technology, which is applied in the field of mechanical devices, can solve the problems that fixed positioning pins cannot adjust the position of the lower die, etc., and achieve the effects of simple device structure, improved stamping accuracy, and improved position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

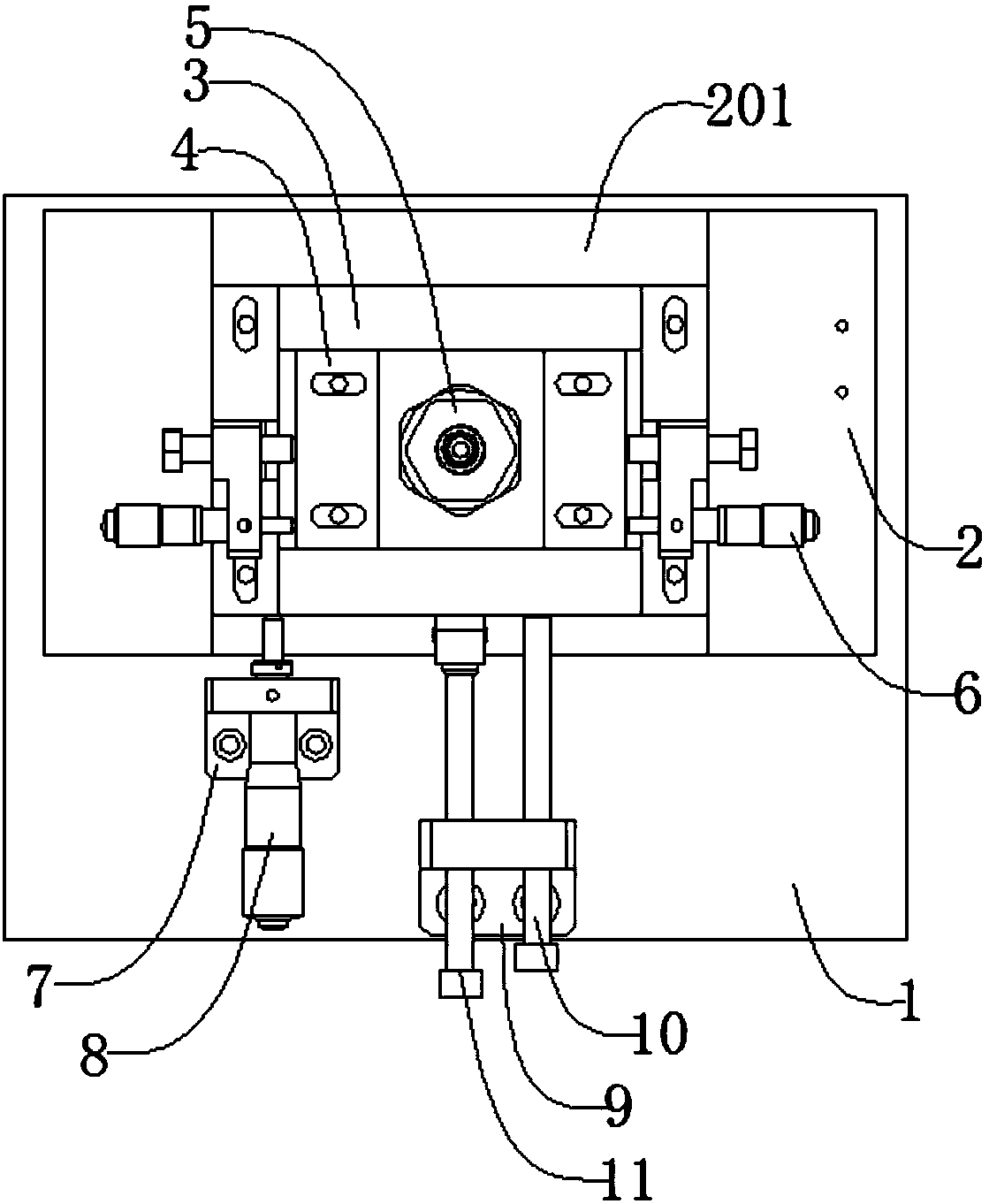

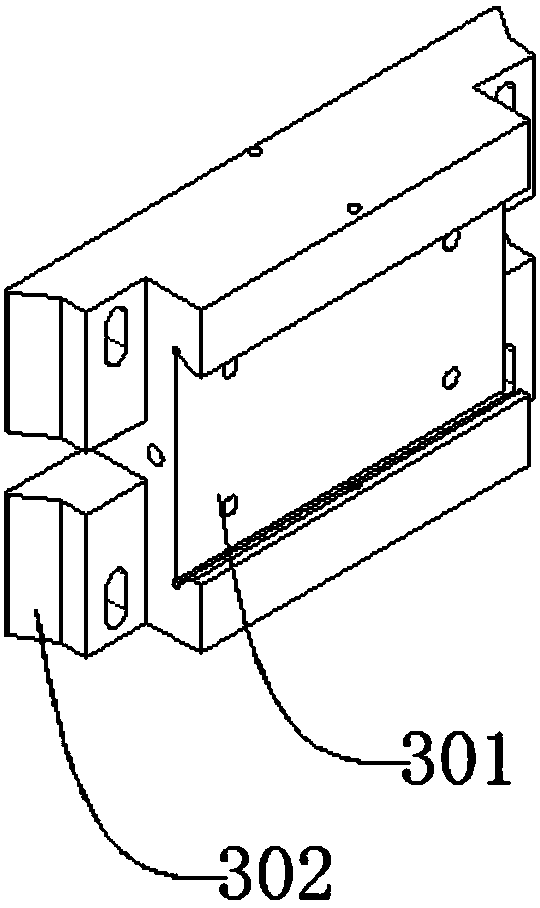

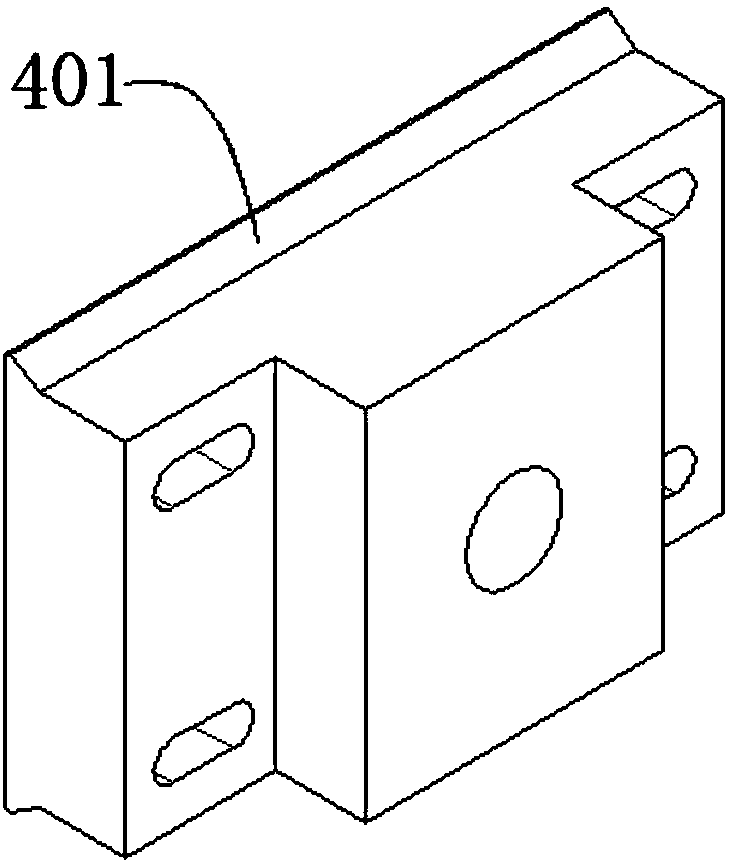

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a position-adjustable lower mold includes a bottom plate 1, a first fixed seat 2, a second fixed seat 3, a mold base 4, a lower mold 5, a horizontal fine-tuning mechanism 6, a first support 7, and a first millisecond Ruler knob 8, second support 9, longitudinal adjustment screw 10, longitudinal adjustment mechanism 11, the first fixed seat 2 is on the top of the bottom plate 1, the first fixed seat 2 is connected with the top plate 1 by bolts, the The second fixed base 3 is located at the top of the first fixed base 2, the second fixed base 3 is connected with the first fixed base 2 by bolts, the mold base 4 is located at the top of the second fixed base 3, and the mold base 4 is located at the top of the second fixed base 3. The seat 4 is connected with the second fixed seat 3 by bolts, the lower die 5 is located at the top of the die seat 4, the lower die 5 is threadedly connected with the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com