Yaw brake machine tool

A technology of yaw brakes and processing machine tools, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve problems affecting the order production cycle and delivery time, hidden dangers of personal safety, and high labor intensity of workers, so as to reduce labor costs. Effect of cost and labor intensity, improvement of production efficiency and clamping accuracy, and improvement of tool processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

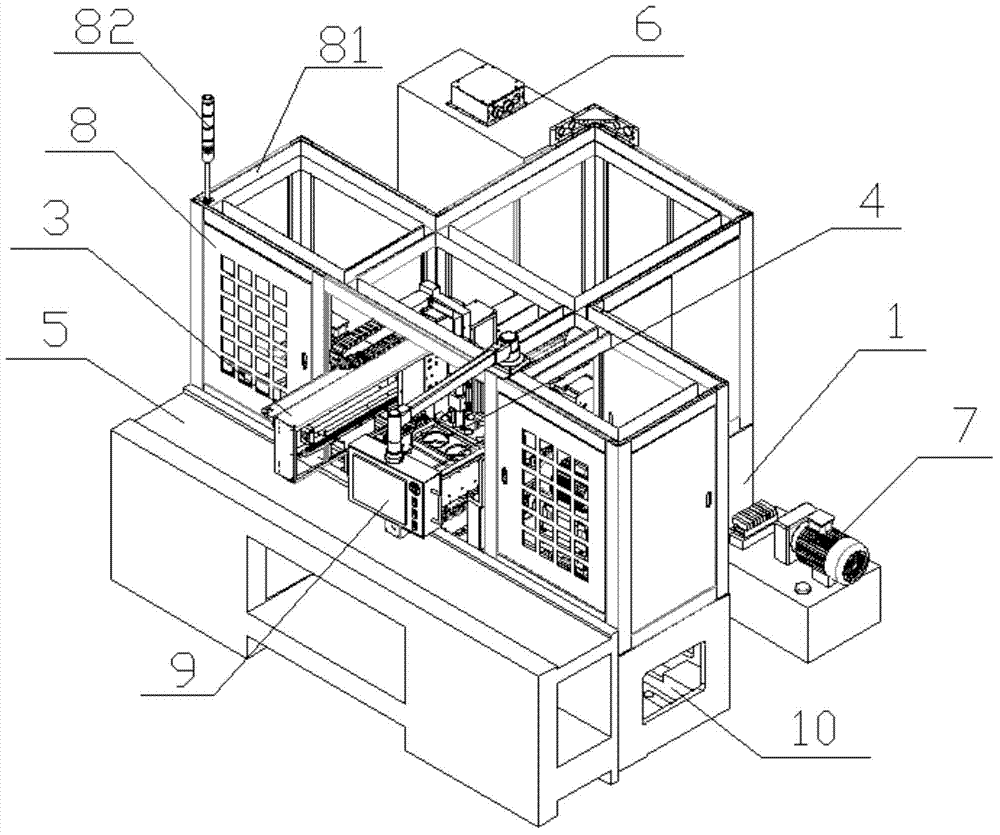

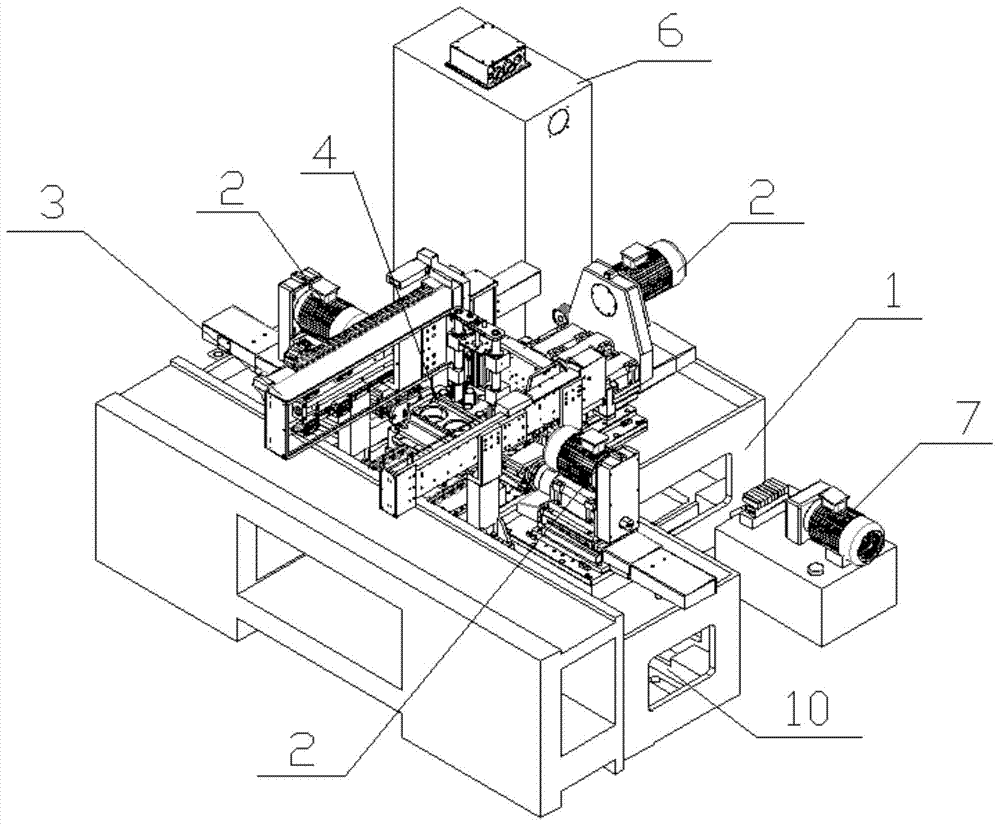

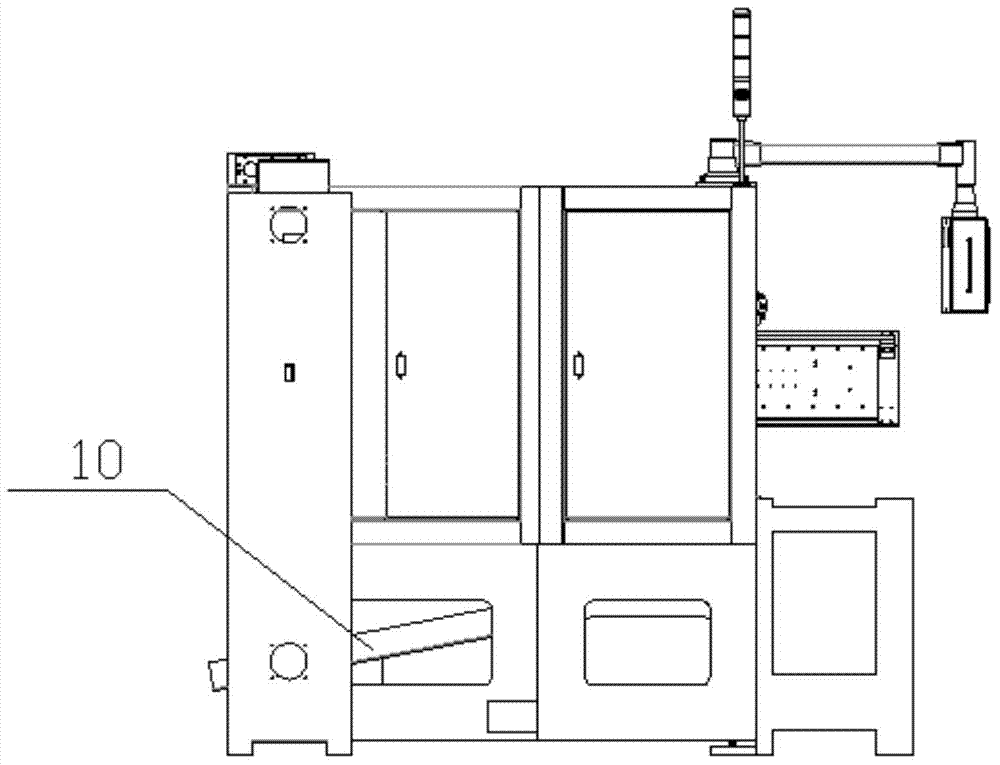

[0032] like figure 1 , figure 2 As shown, the yaw brake processing machine tool includes machine base 1, tool system 2, manipulator system 3, workpiece clamping auxiliary system 4, assembly line workbench 5, electrical control system 6 and hydraulic system 7, mast protection alarm system 8, operation Display unit 9. The machine base 1 has an inverted T-shaped structure; the tool system 2 consists of three tool units, left, right, and rear, which are respectively installed on the left, right, and rear positions of the inverted T-shaped machine base 1; the manipulator system 3 is located between the left and right tool units; the workpiece clamping auxiliary system 4 is fixed on the machine base 1, located below the manipulator system 7; the assembly line workbench 5 is fixed on the front end of the machine base 1, and the assembly line workbench 5 corresponds to A sensor (not shown) and a jacking cylinder (not shown) are arranged at the position of the manipulator; the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com